2.2

ELECTROSTATIC DISCHARGE

CAUTION

FURNACE RELIABILITY HAZARD

Failure to follow this caution may result in unit

component damage. Electrostatic discharge can

affect electronic components. Take precautions

during furnace installation and servicing to

protect the furnace electronic control.

These

precautions will help to avoid exposing the control

to electrostatic discharge by putting the furnace,

the controls, and the technician at the same

electrostatic potential.

1. Disconnect all power to the furnace.

Multiple

disconnects may be required. DO NOT TOUCH

THE CONTROL OR ANY WIRE CONNECTED

TO THE CONTROL PRIOR TO DISCHARGING

YOUR BODY’S ELECTROSTATIC CHARGE TO

GROUND.

2. Firmly touch the clean, unpainted, metal surface of

the furnace chassis which is close to the control.

Tools held in a person’s hand during grounding will

be satisfactorily discharged.

3. After touching the chassis, you may proceed to

service the control or connecting wires as long as

you do nothing to recharge your body with static

electricity (for example; DO NOT move or shuffle

your feet, do not touch ungrounded objects, etc.).

4. If you touch ungrounded objects (and recharge your

body with static electricity), firmly touch a clean,

unpainted metal surface of the furnace again before

touching control or wires.

5. Use this procedure for installed and uninstalled

(ungrounded) furnaces.

6. Before removing a new control from its container,

discharge your body’s electrostatic charge to

ground to protect the control from damage. If the

control is to be installed in a furnace, follow items

1 through 4 before bringing the control or yourself

in contact with the furnace. Put down all used and

new controls before touching ungrounded objects.

7. An ESD service kit (available from commercial

sources) may also be used to prevent ESD

damage.

2.3

LOCATION

This furnace must :

• Be installed so the electrical components are

protected from water;

• Not be installed directly on any combustible

material other than wood flooring;

• Be located close to the chimney or vent and

attached to an air distribution system.

Refer to

section 7

Place the unit so that proper venting can be achieved,

with a minimum number of elbows, in accordance with

the instructions in this manual. The furnace should be

located as close to the chimney (vertical venting) or to

the outside vent wall (horizontal venting) as possible.

When installing the furnace, provisions must be made

to ensure the supply of adequate combustion and

ventilation air in accordance with the “air for combustion

and ventilation” section of the National Fuel Gas Code,

NFPA 5/ANSI Z223. c1 or applicable provisions of the

local building code.

2.3.1

Clearance and accessibility

Installations must provide ample space for servicing and

cleaning. Always comply with minimum fire protection

clearances shown in table 2 or on the furnace rating label.

Clearances must also accomodate an installation’s gas,

electrical, drain trap and venting/combustion air piping. If

the combustion air is installed to the side of the furnace,

additionnal clearance must be provided.

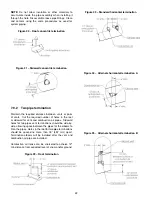

2.3.2

Location relative to cooling

equipement

The cooling coil can either be installed in the supply air

duct or in the return air duct. If the coil is installed in

the supply air duct, it must be at a minimum of 6" over

the furnace’s primary heat exchanger. This will avoid

potential error codes due to heated refrigerant when the

gas furnace is on. It also allows for a more laminar airflow

through the coil. The cooling coil base can be purchased

through your local distributor. See part list tables for the

appropriate item number.

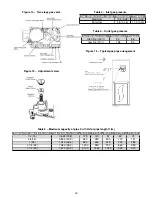

Table 2 – Minimum clearance

Position

Clearance in (mm)

Rear

0

Front

1

24 (610)

All sides of supply plenum

2

1 (25)

Sides

3

0

Vent

0

Top of furnace

1 (25)

1- For servicing or cleaning, a 24" front clearance is

required.

2- For at least the first 3 ft of plenum from furnace

3-Unit connections (electrical, drain trap and combustion

air) may necessitate greater clearances than the

minimum clearances listed above.

7

Summary of Contents for C105-1-D

Page 24: ...Figure 26 Alternate horizontal termination C Figure 27 Venting gasket 23...

Page 25: ...Figure 28 Direct vent clearance 24...

Page 26: ...Figure 29 Other than Direct vent clearance 25...

Page 34: ...Figure 32 Single Stage PSC Wiring diagram...

Page 35: ...Figure 33 Two Stage PSC Wiring diagram...

Page 36: ...Figure 34 Single Stage ECM Wiring diagram...

Page 39: ...Figure 35 Dimensions 38...

Page 40: ...Figure 36 Exploded view CXX 1 X part 1...

Page 41: ...Figure 37 Exploded view CXX 1 X part 2...

Page 43: ...Figure 38 Exploded view Cxx 1 D part 1...

Page 44: ...Figure 39 Exploded view Cxx 1 D part 2...

Page 46: ...Figure 40 Exploded view Cxx 2 D part 1...