6. Deburr the inside and outside of the pipe.

7. Chamfer the outside edge of pipe for better

distribution of primer and cement.

8. Clean and dry all surfaces to be joined.

9. Check dry fit of the pipe and mark insertion depth

on the pipe.

10. After the pipes have been cut and preassembled,

apply a generous layer of cement primer to the pipe

fitting socket and end of the pipe to insertion mark.

Quickly apply approved cement to end of the pipe

and fitting socket (over primer). Apply cement in a

light, uniform coat on the inside of socket to prevent

build-up of excess cement. Apply second coat.

11. While cement is still wet, twist pipe into the socket

with 1/4” turn. Be sure the pipe is fully inserted into

the fitting socket.

12. Wipe excess cement from the joint. A continuous

bead of cement will be visible around perimeter of

a properly made joint.

13. Handle pipe joints carefully until cement sets.

14. Horizontal portions of the venting system shall be

supported to prevent sagging. Support any piping

at a minimum of every 5 ft. using perforated metal

hanging strap or commercially available hangars

designed to support plastic pipe.

15. Prevent condensate from accumulating in the pipes

by sloping the combustion air piping and vent piping

downward toward furnace a minimum of 1/4” per

linear ft. with no sags between hangers.

16. Complete the vent installation by installing the

required termination.

allowed termination.

17. Use appropriate methods to seal the openings

where combustion air pipe and vent pipe pass

through roof or sidewall.

8.8

COMBUSTION AIR

Use a 90° elbow or two medium-radius sweep elbows to

keep the inlet downward and prevent the entry of rain.

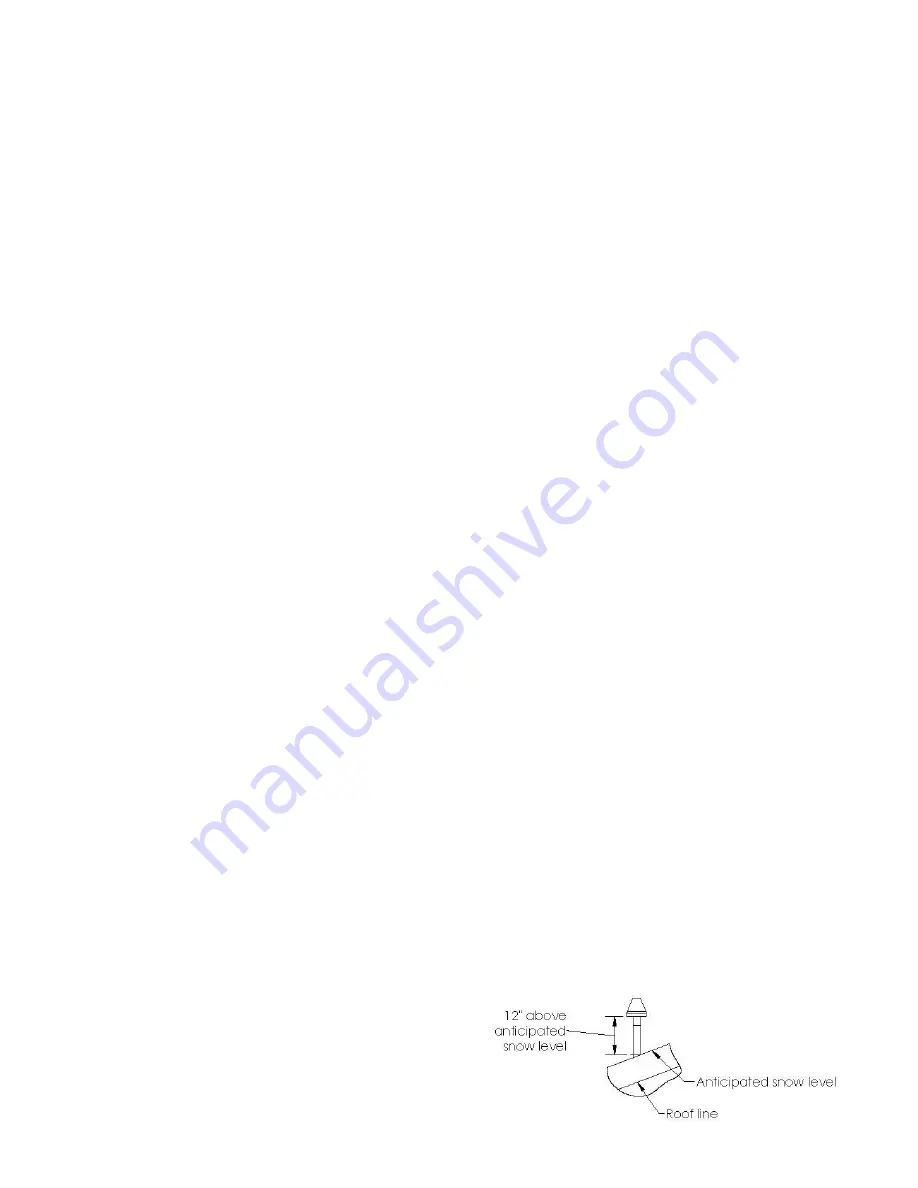

The inlet opening of the combustion air termination must

be a minimum of 12” above the anticipated level of snow

accumulation.

Horizontal combustion air pipe should have a drain

tee assembly and trap installed in the as close to

the furnace as possible.

This is to drain any water or

condensate that may enter the furnace vestibule area.

8.9

VENT TERMINATION

All clearance specified in this manual are in accordance

with the current CSA B149.1, Natural and Propane

Installation Code and the current ANSI Z223.1/NFPA 54,

National Fuel Gas Code. For clearance not specified

in these codes, clearance should be in accordance with

local installation codes and the requirements of the gas

supplier and the instructions in this manual.

A vent for this appliance shall not terminate:

-over public walkways;

-near soffit vents or crawl space vents or other areas

where condensate or vapor could create a nuisance or

hazard;

-near regulators, relief valves, or other equipment where

condensate or vapor could be detrimental to their

operation;

See figures 25 and 26 for venting clearance.

8.9.1

Concentric vent

Concentric vent can cause ice build up at the termination

and cause the furnace to shut off. Especially this high

efficiency furnaces having an input below 15,000 BTU/hr.

In these installations, flue gases are not expelled at a

velocity to prevent ice formation and residual energy in

the flue is not high enough to prevent ice formation. If

a concentric vent is to be use with these low input, intall

a 1.5" diameter pipe within the 2" diameter pipe

in the

concentric

. Vent before the concentric shall remain 2"

diameter. This will enhance flue gas speed at the end of

the pipe and will reduce the risk of ice build up.

It might be necessary to add a heat strip

within

the

termination.

For multiple concentric installation, spacing of minimum

12" between each concentric is required.

Figures 18

and 19 show the required clearance for concentric

installation.

For installation through the roof or side wall, cut one 4”

(102 mm) diameter hole for 2” (51 mm) kit, or one 5”

(127 mm) diameter hole for 3” (76 mm) kit in the desired

location. Loosely assemble concentric vent/combustion

air termination components together following the kit

instructions.

Slide the assembled kit with rain shield

REMOVED through the hole in the wall or roof flashing.

NOTE

: Do not allow insulation or other materials to

accumulate inside the pipe assembly when installing it

through the hole. Disassemble loose pipe fittings. Clean

and cement using the same procedures as used for

system piping.

Figure 18 – Roof concentric termination

21

Summary of Contents for CC15-M-V

Page 18: ...Figure 17 Wiring Diagram 18...

Page 23: ...Figure 25 Direct vent clearance 23...

Page 24: ...Figure 26 Other than Direct vent clearance 24...

Page 34: ...12 PART LIST Figure 27 Exploded view...

Page 35: ...Figure 28 Exploded view continued...

Page 36: ...Table 19 Part list Chinook Compact...

Page 37: ...Table 20 Part list continued...

Page 38: ...13 NOTES 38...

Page 39: ...39...

Page 40: ...40...