9

deliver a temperature rise within the range specified on the

rating plate, between the return and supply pressure at the

external duct static pressure noted on the rating label.

Adjust the fan speed ACCORDING TO THE OIL INPUT

SELECTED, so that the temperature rise is within the range

specified on the rating plate (see Table 2). Consult the

wiring diagram for speed changes on the direct drive motor.

In the oil mode, the blower start / stop is controlled by a

helical bi-metal Fan-Limit Control, which is adjusted to start

at 110°F and stop at 90°F. These are factory set li mits and

must not be changed or tampered with.

3.2.5

Limit Control check

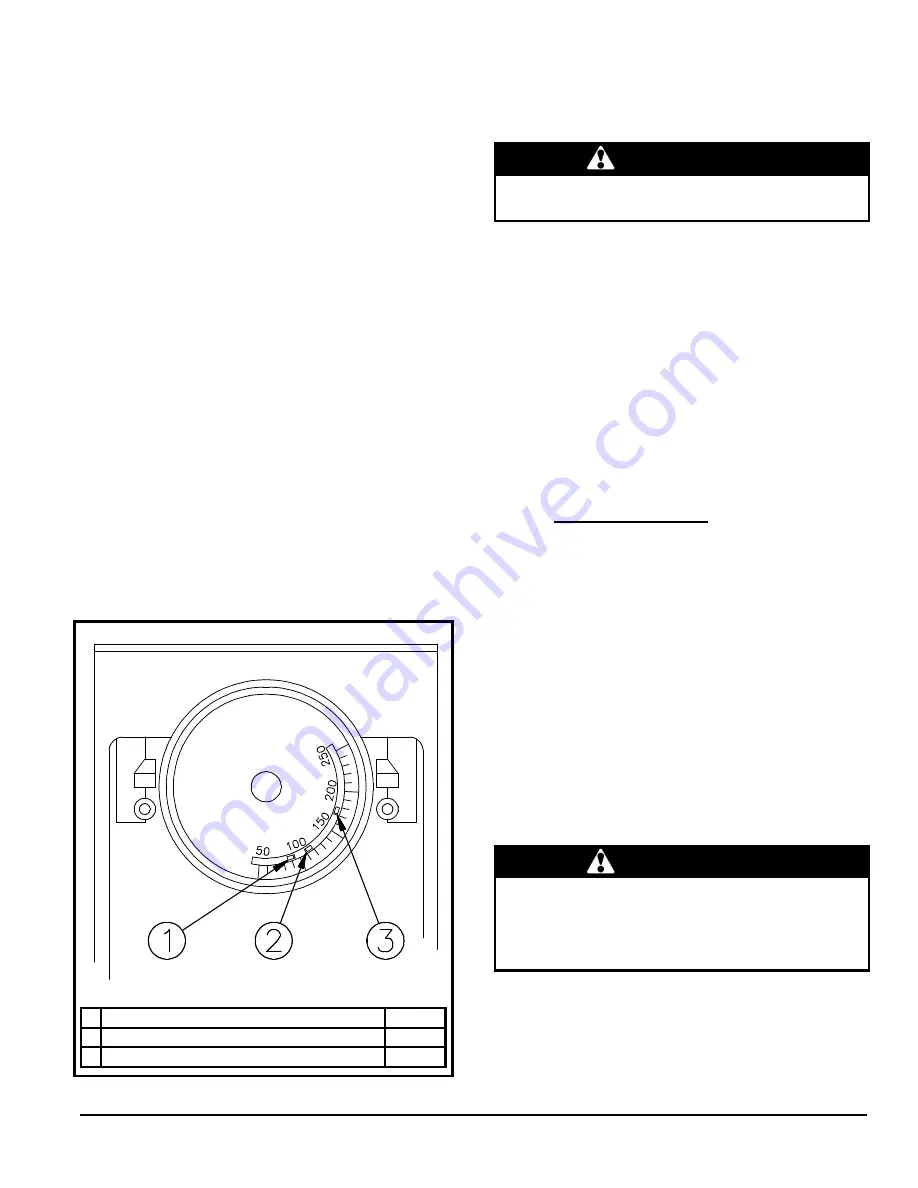

The Limit Control is factory adjusted according to Figure 1.

After the furnace has been in operation for at least 15

minutes, restrict the return air supply by blocking the filters or

closing the return registers and allow the furnace to shut

down on high limit. The burner will shut OFF and the main

blower should continue to run.

Remove the restriction and the burner should come back on

in a few minutes.

Constant Blower Switch

This furnace is equipped with a constant low speed blower

option. Whenever the room thermostat is not calling for

heating or cooling, the blower will run on low speed in order

to provide air circulation. If this constant blower option is not

desired, the rocker switch on the side of the control box can

be used to turn off this feature.

Figure 1 : Limit Control adjustment

DNS-0355 Rev A

1 Limit “FAN OFF”

90°F

2 Limit “FAN ON”

110°F

3 Limit “HI”

190°F

3.2.6

Limit Control adjustment

Changing the Low Limit "FAN ON" and limit "HI" on the Fan

limit control can cause malfunction of the furnace and cause

premature wear of the heat exchanger.

CAUTION

Modification of the factory set limits will void the

warranty.

3.2.7

BVSO performance test

The purpose of the following test is to check that the

electrical outlet on the furnace, designated to the BVSO, is

functional.

1. Start up the burner;

2. Remove the three-pole plug from the BVSO outlet on

the furnace;

3. The burner must shut-off immediately, while the blower

continues to run to the end of the cool-down cycle.

If the test is not in line with the above, call a QUALIFIED

SERVICE TECHNICIAN.

4.0 MAINTENANCE

This furnace should never be operated without an air filter.

Disposable filters should be replaced at least once a year. If

equipped to provide cooling, filters should be replaced a

minimum of twice a year.

In order to avoid injuries, be sure to cut the power to the unit

before commencing maintenance work.

For optimum performance, the oil burner nozzle should be

replaced at least once a year. Contact an authorized service

technician if you are unsure of this procedure.

The procedure for the installation and/or replacement of a

nozzle is outlined in the oil burner instruction manual that is

supplied with the furnace.

After replacing the nozzle, the burner should be adjusted in

accordance with the “COMBUSTION CHECK” section of this

manual.

WARNING

Be sure to turn all power “OFF” upstream from the unit

when servicing the furnace, unless power is required for

specific operations. Failure to comply with this

CAUTION can result in bodily harm and/or cause a fire

hazard.

4.1

HEAT EXCHANGER CLEANING

Ordinarily, it is not necessary to clean the heat exchanger or

flue pipe every year, but it is advisable to have a qualified

service technician check the unit before each heating

season to determine whether cleaning or replacement of

parts is required.

Summary of Contents for LOW-BOY AME15-79

Page 16: ...16 Figure 5 D montage du tiroir d l ment...

Page 17: ...17 Figure 6 Diagramme lectrique...

Page 18: ...18 Figure 7 Liste de pi ces B50047 Rev A...

Page 35: ...15 Figure 5 Element drawer removal...

Page 36: ...16 Figure 6 Electrical Diagram...

Page 37: ...17 Figure 7 Parts List B50047 Rev A...

Page 40: ...20...