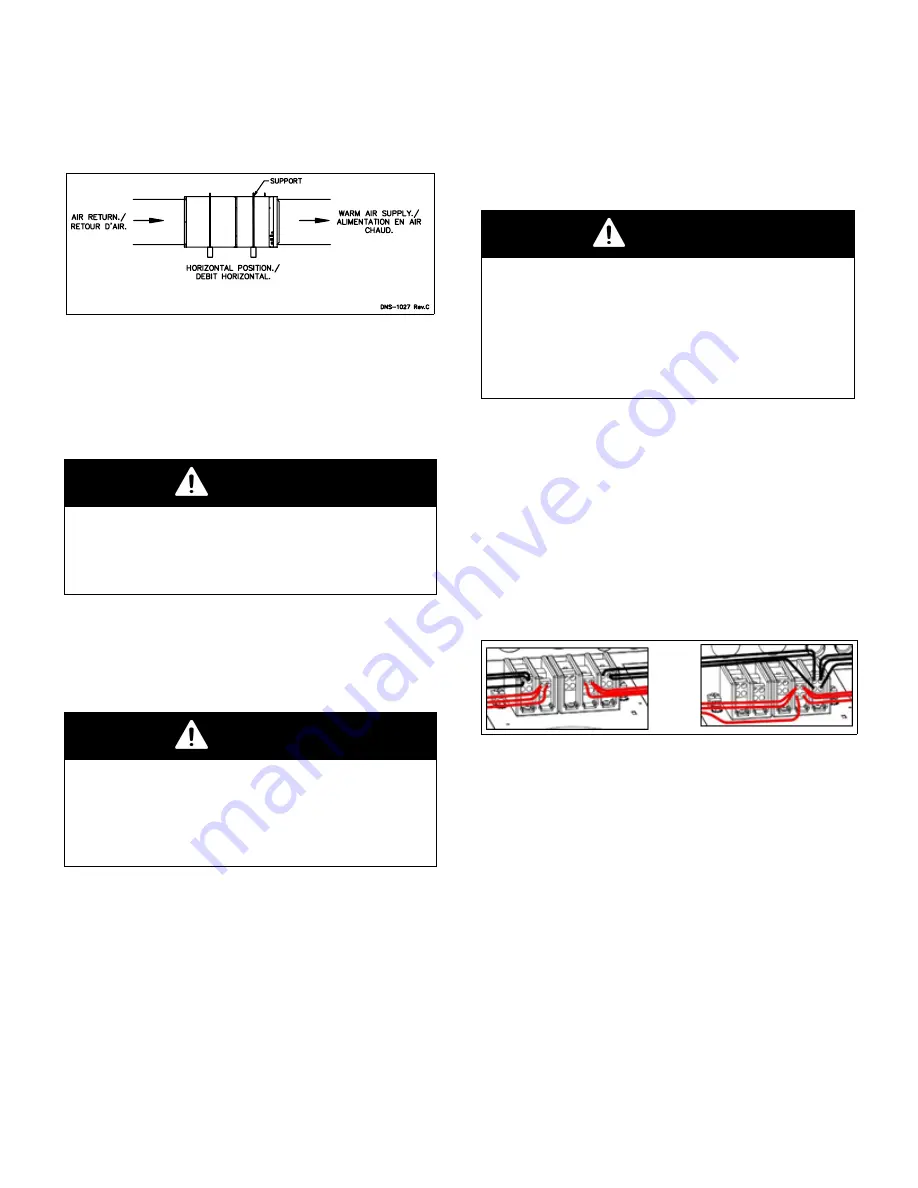

either suspended or on a combustible floor with a choice

of right or left discharge, the clearances from combustible

material must be adhered to. Refer to Figure 3 for addi-

tional details.

Figure 3: Horizontal Configuration

2.3.4

Suspended installation

The furnace can be hanged to the ceiling in either up-

flow, downflow or horizontal. Make sure to mount it ap-

propriately and to respect the clearances to combustible

material.

WARNING

The furnace must be properly secured especially

when installed above living space.

Failure to follow this rule can result in death, bod-

ily injury and/or property damage.

2.4

ELECTRICAL SYSTEM

The S

UPREME

furnace is completely pre-wired and all

field wiring must be connected to the terminal blocks on

the unit. It requires 2 service wires of 120/240 - 208 volts.

WARNING

R

ISK OF FIRE

The conductor sizing must conform to the last edi-

tion of the local or national codes.

Failure to follow this rule can result in death, bod-

ily injury and/or property damage.

Power supply to the unit can be done using cop-

per or aluminum wires. The wire size must be decided in

accordance to unit power consumption, the over current

protection type and capacity, the wire type and length,

and the environment where the unit is installed. If an alu-

minum wire is used, other precautions must be taken to

insure the conformity of the installation. In all cases, all

the factors affecting the wire gauge must be considered

and the installation codes followed.

The exterior of the unit must have an uninterrupted

ground to minimize the risk of bodily harm. A ground

terminal is supplied with the control box for that purpose.

A connector is supplied on the ground terminal to ground

an added accessory.

In the event that wires inside the unit require replace-

ment, these must be copper wires only with same tem-

perature rating and sizes as originals.

2.4.1

Conversion from two wires to one

wire supply for models 25kW and

more

WARNING

R

ISK OF FIRE

When using one terminal block on models of 25kW

and higher, the installation must be performed

with copper wire ONLY in order to comply with the

Canadian electrical code. The usage of an alu-

minum or copper wire is acceptable on models

25kW and lower.

Move all wires from the two pole terminal to the

three pole terminal following the corresponding colors as

shown in Figure 4.

The breaker and the supply conductors must be sized by

adding the ampacities of the two terminals indicated on

the nameplate. Refer to electrical diagram Figure 16.

Figure 4: Conversion from two to one supply wires

2.5

INSTALLATION OF THE

THERMOSTAT

A thermostat must be installed to control the temperature

of the area to be heated. Follow the instructions supplied

with the thermostat. Some thermostats need to connect

the C terminal on the furnace and thermostat. Install the

thermostat on an interior wall in a location where it will

not be subject to direct sunlight, lamps, air diffusers, fire-

places, etc. Seal openings in walls to avoid air currents

that may influence the operation of the thermostat. Also

refer to the wiring diagrams provided with the heating/air

conditioning unit. The connections must be made as in-

dicated on Figure 5 to Figure 9. Refer to the electrical

diagram (Figure 16).

4