4

If the static pressure is high in the supply duct because of a

large duct system or the addition of a cooling coil, it is

suggested to close down the louvers until the noise or the

vibration is decreased to a normal level. To limit the airflow

or to increase the temperature differential, it is possible to

close down the louvers. Open up the louvers to have the

reverse effect. To adjust the louvers, push green levers and

engage tack to another hole. It is suggested to place both

louvers at the same position to insure uniform air distribution

through the elements.

2.1

POSITIONING THE FURNACE

WARNING

Fire and explosion hazard.

The furnace must be installed in a level position, never

where it will slope toward the front.

Do not store or use gasoline or any other flammable

substances near the furnace.

Non-observance of these instructions will potentially

result in death, bodily injury and/or property damage.

CAUTION

This furnace is not watertight and is not designed for

outdoor installation. It must be installed in such a

manner as to protect its electrical components from

water. Outdoor installation will lead to a hazardous

electrical condition and to premature failure of the

equipment.

If the furnace is installed in a basement or on a dirt floor, in a

crawl space for example, it is recommended to install the

unit on a cement base 2.5 cm to 5.0 cm (1’’ to 2’’) thick.

The unit must be installed in an area where the ambient and

return air temperatures are above 15

˚

C (60

˚

F). In addition,

the heater should also be located close to the center of the

air distribution system.

2.2

CLEARANCES TO COMBUSTIBLE MATERIAL

2.2.1. Heating

unit

The furnace is approved for zero clearance to combustible

material regardless of the heating capacity.

2.2.2.

Supply air ducts

Ducts for furnaces with a heating capacity up to and

including 20 k W, can be installed with a zero clearance to

combustible material.

Ducts for furnaces of 23 kW or more must have a clearance

of 25 mm (1’’) to combustible material for the first 0.9 m (36’’)

of duct. Thereafter the clearance can be zero.

Units of 23 kW and up, installed in the downflow position

must use a DFB-FEM downflow base, which is especially

designed for this purpose. It ensures that the required

clearances are being adhered to.

2.3 CONFIGURATIONS

This furnace requires suitable ductwork.

In upflow installation, the return duct may be installed to the

back, on the left, or on the right of the unit.

In downflow or horizontal installation, the return duct may be

installed to the back, on the left side, on the right side or

under the unit.

In all configuration, the supply duct shall be installed on the

top of the unit.

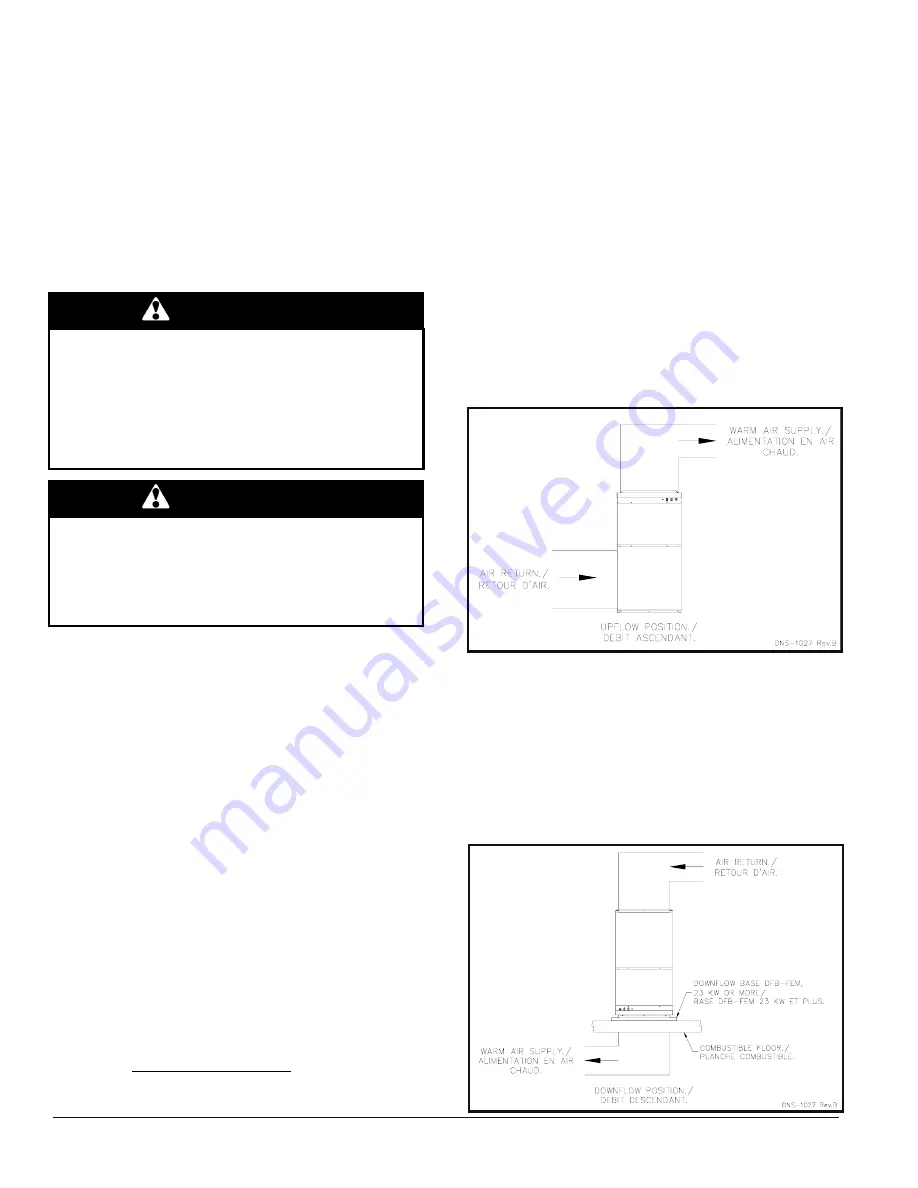

2.3.1. Upflow installation

The return duct may be installed to the back, on the left side

or on the right side of the unit. Care should be taken not to

damage the wires inside, while cutting the opening. Install

the filter rack supplied with the unit according to the

instructions provided with it. It is also recommended to

install the blower door before handling or moving the unit.

Refer to Figure 1 for additional details.

Figure 1: Upflow installation

2.3.2. Downflow

installation

The return duct may be installed to the back, on the left side,

on the right side or under the unit.

When the furnace is installed in the downflow position on a

combustible floor, the clearances from combustibles

materials must be adhered to. The downflow base DFB-

FEM can be used to ensure these clearances. Refer to

Figure 2 and the installation instructions provided with the

base.

Figure 2: Downflow installation

Summary of Contents for SUPREME SUP10-M2401A

Page 11: ...11 Figure 9 Furnace dimensions...

Page 12: ...12 Figure 10 Wiring diagram 3 wires 10 kW...

Page 13: ...13 Figure 11 Wiring diagram 3 wires 15 kW...

Page 14: ...14 Figure 12 Wiring diagram 3 wires 18 20 kW...

Page 15: ...15 Figure 13 Wiring diagram 3 wires 23 kW...