6

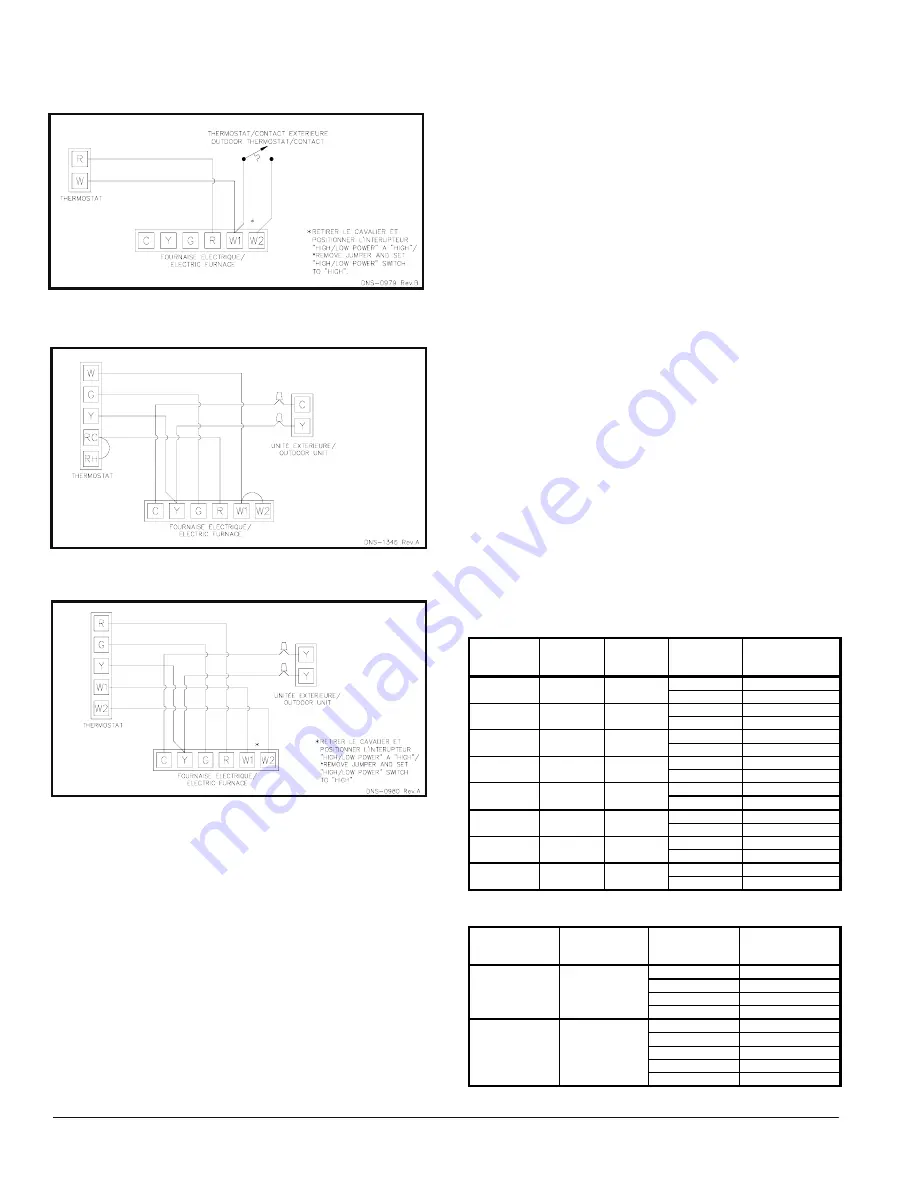

Figure 6: 1-stage thermostat with outdoor control for 2-

stage function, electric heating only

Figure 7: 1-stage thermostat, electric heat and cooling

application

Figure 8: 2-stage thermostat, electric heating and air

conditioning

2.5.2.

Ducts and filters

The ducts must be sized such a way as to accommodate the

specified airflow and the available static pressure. Refer to

the applicable local and/or national installation codes.

Insulate the ducts that lead through non-heated areas. Use

flexible supply and return air connectors to avoid the

transmission of vibration. To make the unit run even quieter,

the installer should:

1. Use two elbows between each outlet and the supply and

return air plenum;

2. Cover the vertical sections of the supply and return air

duct with soundproofing material;

3. Use baffles in short radius elbows;

4. Use flexible hangers to suspend the ducts.

The

SUPREME

furnace is equipped with a filter frame for the

blower compartment. It must be installed on the outside of

one of the three sides or the bottom of the furnace. Once

the location of the installation has been determined, use the

four square knockouts for ease of cutting the opening.

A heat pump or an air conditioner can be added to this

furnace, in either the supply or return air duct. Carefully

follow the instructions provided with these appliances to

ensure proper installation and hook-up to the electric

furnace. Refrigerant and drainage pipes must in no way

hinder access to the furnace panels.

2.6 SUPPLY

AIR

ADJUSTMENTS

On units equipped with 4-speed blower motors, the supply

air must be adjusted based on heating/air conditioning

output and the static pressure of the duct system. For the

desired airflow, refer to the Table 1 and 2, as well as the

Tables 4 and 5 for the airflow based on static pressure.

For the adjustment of the airflow on heating mode, to obtain

the temperature rise described in the technical specification

table (Table 3), the red wire must be positioned on the

terminal corresponding to the LOW, MED-LOW, MED-HIGH

or HIGH blower speed. Blower speeds are adjusted in

factory for 0.5 inch static pressure.

For the adjustment of the airflow on air-cooling mode, to

obtain a sufficient airflow (350 to 450 CFM per Ton), the blue

wire must be positioned on the terminal corresponding to the

LOW, MED-LOW, MED-HIGH or HIGH blower speed.

Blower speeds are adjusted in factory for 0.5 inch static

pressure.

Table 1: Supply air adjustment on heating mode

FURNACE

INPUT

POWER

KW

HP

MOTOR

STATIC

PRESSUR

E (in. w.c)

RECOMMENDE

D BLOWER

SPEED

0.2 LOW

SUP10 10 1/3

0.5 LOW

0.2 MED-LOW

SUP15 15 1/3

0.5 MED-LOW

0.2 MED-LOW

SUP18 18 1/3

0.5 MED-LOW

0.2 MED-LOW

SUP20 20 1/3

0.5 MED-HIGH

0.2 MED-HIGH

SUP23 23 1/3

0.5 MED-HIGH

0.2 MED-LOW

SUP20 20 1.0

0.5 MED-LOW

0.2 MED-LOW

SUP23 23 1.0

0.5 MED-LOW

0.2 MED-LOW

SUP27 27 1.0

0.5 MED-LOW

Table 2: Supply air adjustment on air cooling mode

FURNACE HP

MOTOR

COOLING

CAPACITY

(0.5” w.c.)

RECOMMENDED

BLOWER SPEED

1.5 LOW

2.0 MED-LOW

2.5 MED-HIGH

SUP10, 15, 18,

20 and 23

1/3

3.0 HIGH

2.5 LOW

3.0 MED-LOW

3.5 MED-HIGH

4.0 HIGH

SUP20, 23 and

27

1.0

5.0 HIGH

Summary of Contents for SUPREME SUP10-M2401A

Page 11: ...11 Figure 9 Furnace dimensions...

Page 12: ...12 Figure 10 Wiring diagram 3 wires 10 kW...

Page 13: ...13 Figure 11 Wiring diagram 3 wires 15 kW...

Page 14: ...14 Figure 12 Wiring diagram 3 wires 18 20 kW...

Page 15: ...15 Figure 13 Wiring diagram 3 wires 23 kW...