© 0303

300200054-en-00.fm

Page Page 3

●

Open the bleeding screws 8.

●

Remove the filter cartridges 5 from the filter housing and clean the inside

of the filter housing.

●

Insert new filter cartridges in the housing and replace the covers in

reverse order, be careful with the gaskets.

●

Open the bleeding screws 8 and run the hand pump until fuel emerges

without air bubbles. Close the bleeding screws 8 again whilst continuing

pumping. Drain surplus fuel from the side.

●

Set the tap on both filters to open.

●

Check the filters for leaks during operation.

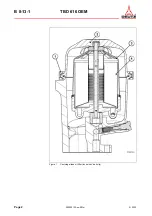

Figure 4

Middle screws and cover

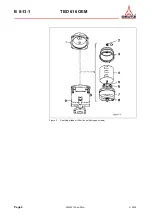

Figure 5

Filter cartridges

3

8

4

5

Summary of Contents for TBD 616 OEM

Page 1: ...Operating Instructions TBD 616 OEM Operating Instructions TBD 616 OEM ...

Page 2: ......

Page 138: ...Chapter 8 Page 6 300200137 en 00 fm 0103 Technische Angaben TBD 616 OEM ...

Page 154: ...Page 6 300200048 en 00 fm 0303 B 0 1 5 TBD 616 OEM This page intentionally left blank ...

Page 176: ...Seite Page 8 300200051 en 00 fm 0303 B 7 3 1 TBD 616 OEM This page intentionally left blank ...

Page 178: ...Seite Page 2 300200052 en 00 fm 0303 B 7 4 16 TBD 616 OEM This page intentionally left blank ...

Page 190: ...Page Page 2 300200060 en 00 fm 0303 B 7 10 4 TBD 616 OEM This page intentionally left blank ...

Page 194: ...Page 4 300200055 en 00 fm 0303 B 8 1 2 TBD 616 OEM This page intentionally left blank ...

Page 198: ...Page 4 300200056 en 00 fm 0303 B 8 10 4 TBD 616 OEM This page intentionally left blank ...

Page 210: ...Page 8 300200036 en 00 fm 0303 B 9 0 4 TBD 616 OEM This page intentionally left blank ...

Page 212: ...Page 2 300200029 en 00 fm 0303 B 9 1 1 Diesel Engines This page intentionally left blank ...

Page 214: ...Page Page 2 300200059 en 00 fm 0303 B 9 1 2 TBD 616 OEM This page intentionally left blank ...

Page 216: ...Page 2 300200125 en 00 fm 0303 B 9 7 11 TBD 616 OEM This page intentionally left blank ...

Page 218: ...Page 2 300200126 en 00 fm 0303 B 9 7 12 TBD 616 OEM This page intentionally left blank ...

Page 222: ...Page 2 300200061 en 00 fm 0303 B 11 0 1 TBD 616 OEM This page intentionally left blank ...

Page 224: ...Page 2 300201137 en 00 fm 0303 B 11 0 2 Dieselmotoren This page intentionally left blank ...

Page 244: ...Page Page 12 300200062 en 00 fm 0303 B 12 2 1 TBD 616 OEM This page intentionally left blank ...