7

COOLING MEDIUM*

AMBIENT

TEMPERATURE

MULTIPLIER

°

F

°

C

80

27

1.12

90

32

1.06

100

38

1.00

110

43

0.94

INLET COMPRESSED AIR CONDITIONS

INLETINLET TEMPERATURES

PRESSURES

80

°

F

90

°

F

100

°

F

110

°

F

120

°

F

psig

kgf/cm

2

27

°

C

32

°

C

38

°

C

43

°

C

49

°

C

50

3.5

1.35

1.05

0.84

0.69

0.56

80

5.6

1.50

1.17

0.95

0.79

0.66

100

7.0

1.55

1.23

1.00

0.82

0.70

125

8.8

1.63

1.31

1.07

0.91

0.74

150

10.5

1.70

1.37

1.13

0.95

0.80

175

12.3

1.75

1.42

1.18

0.99

0.84

200

14.0

1.80

1.47

1.22

1.03

0.89

3.1 Condenser coil—Clean off accumulated dust

and dirt monthly.

3.2 Moisture separator—Replace filter element

when pressure drop across dryer is excessive

or annually.

3.3 Check separator daily to be sure automatic drain

is discharging.

3.4 Blow down separator weekly by pushing test

button on control panel.

3.4 Rebuild drain mechanism annually.

To facilitate service, maintenance kits are available.

3.0 MAINTENANCE

SIZING

Determining dryer capacity at actual operating conditions

To determine the maximum inlet flow capacity of a dryer

at various operating conditions, multiply the rated capacity

from Table 1 by the multipliers shown in Table 2.

Example: How many scfm can an air-cooled model 400

handle when compressed air to be dried is at 200 psig and

100

°

F; ambient air temperature is 80

°

F; and a 40

°

F dew

point temperature is desired?

Answer: 400 x 1.22 x 1.12 x 1.1 = 601 scfm.

TABLE 2

Air capacity correction factors (Multipliers)

MODEL

200

250

300

400

500

750

Rated capacity of

60 Hz

200

250

300

400

500

750

air-cooled models (scfm) 50 Hz

170

210

250

340

420

630

TABLE 1

Rated capacity (scfm) and pressure drop @ 100 psig inlet

pressure, 100

°

F inlet temperature, and 100

°

F ambient

temperature

*Air-cooled models; water-cooled models use 1.15 multiplier if cooling

water is below 35

°

C, 95

°

F.

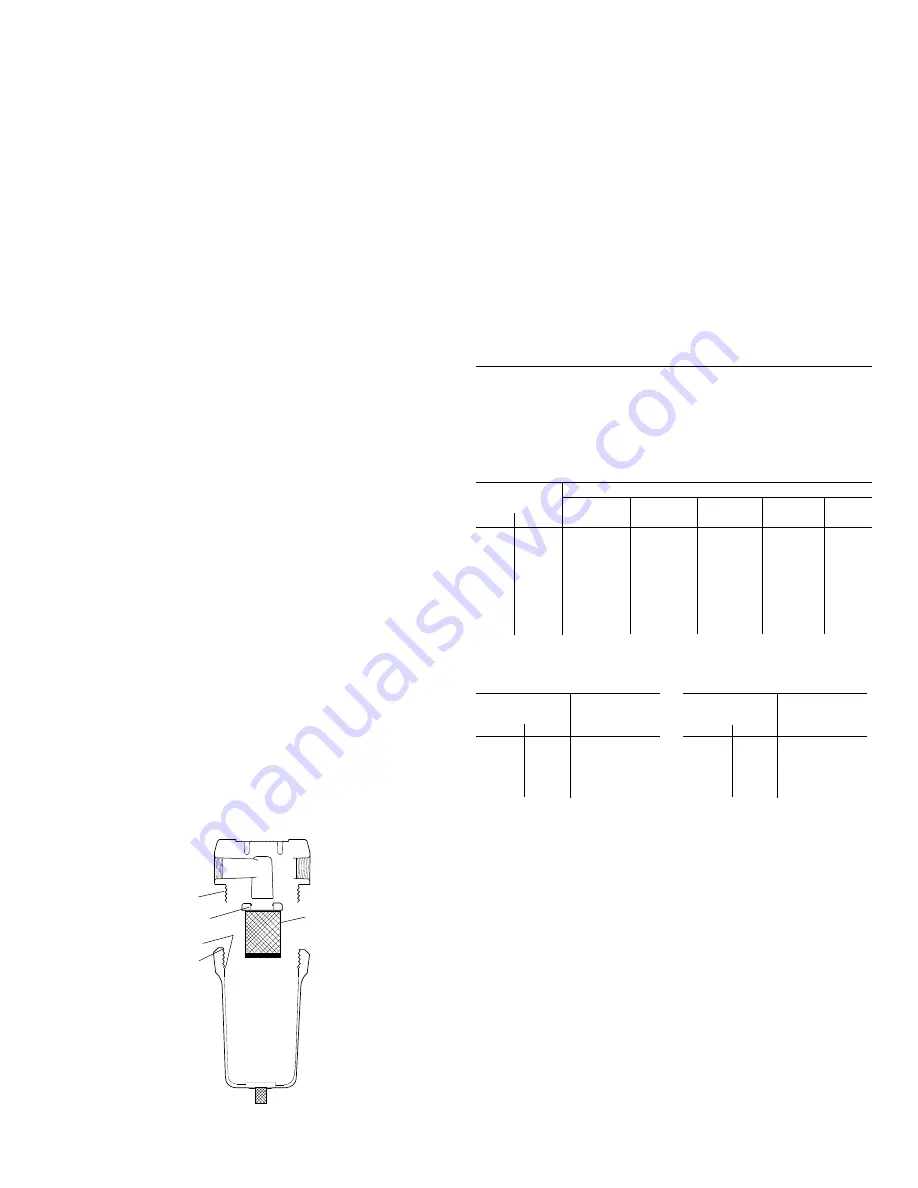

Element o-ring

Separator Element

Bowl o-ring

Threads

Threads

OUTLET DEWPOINT

DEWPOINT

TEMPERATURE

MULTIPLIER

°

F

°

C

38

3

1.0

40

4

1.1

45

7

1.2

50

10

1.3

Dryer Driven Mode- the contacts will be energized

and de-energized in parallel with the refrigeration

compressor of the dryer. Therefore, if the refrigera-

tioncompressor is on, the contacts are energized; if

the refrigeration compressor is off (manually or by a

system fault condition), the contacts will be de-

energized.

NOTE: It is the responsibility of the end-user to properly

design the system control circuitry when using the

auxiliary contact feature.

To select Schedule Driven or Dryer Driven modes:

1.

De-energize unit and disconnect the power

supply to the dryer.

2.

Remove the cabinet panels as necessary to

provide access to the Monitor panel.

3.

On the rear of the circuit board, locate the

jumper pins labeled JA and JB.

4.

Move the jumper to the appropriate setting:

Schedule Driven: jumper position JA

Dryer Driven: jumper postion JB

5.

Wire the auxiliary device into the terminals

1 (Normally Open), 2 (Common) and/or 3

(Normally Closed) on the terminal block TB2.

See wiring diagram for details.

6.

Reinstall the cabinet panels.

7.

Energize the unit.

For Sales & Service Call: 705-722-5747 Ext.1