33 Pictures for illustrating purposes only

E

LECTRO

V

AP

MC2

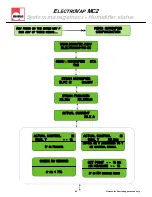

Installation - Step 5

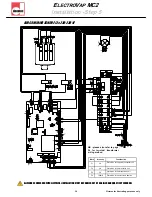

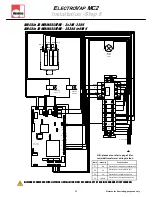

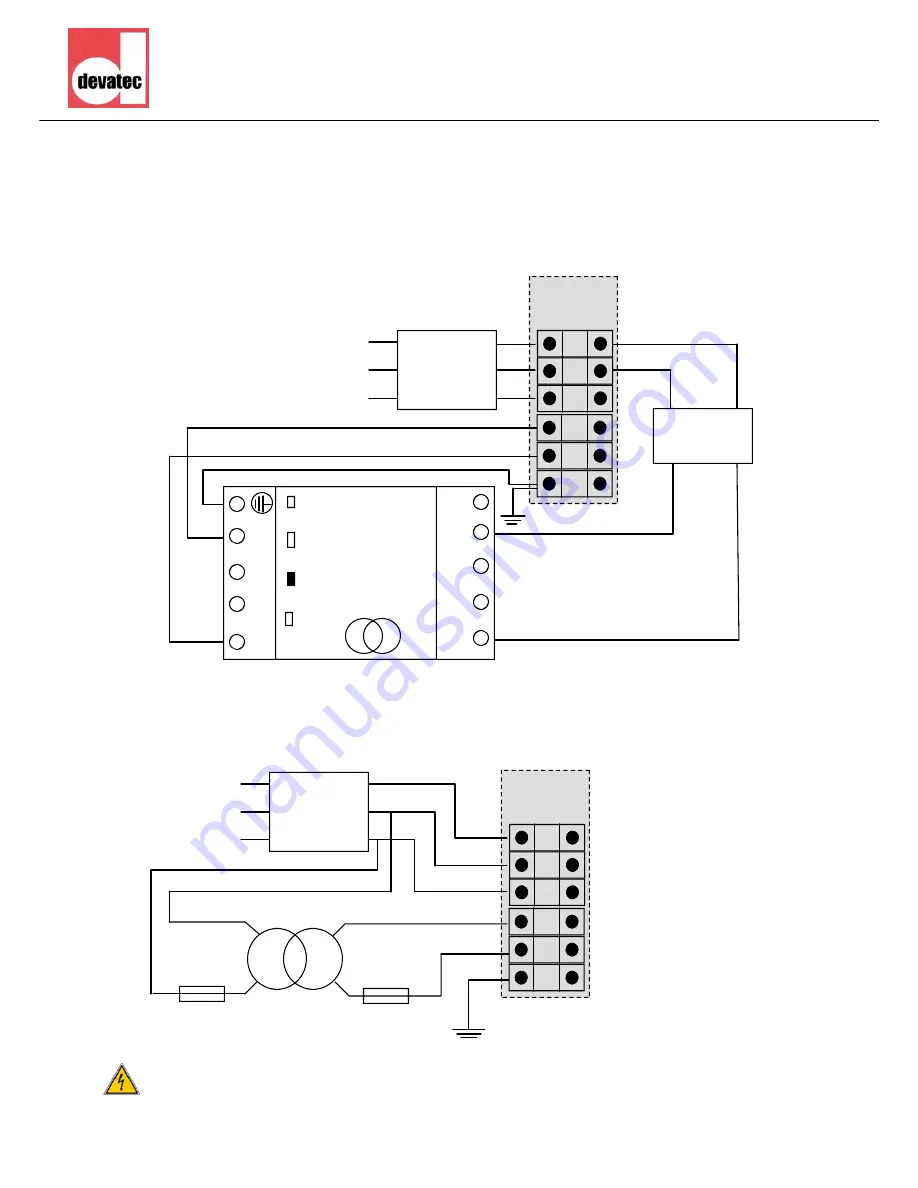

TRANSFOMER (OPTION)

The ELMC 5 to 90 humidifiers are electrically supplied in G + N. In case a neutral line is not

available, this can however be easily substitued by the use of our optional transfomer preventing the

installation of a specific neutral line.

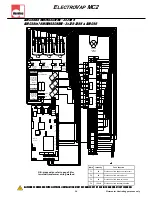

1

2 3

4

+15V

0V

-15V

230V

400V

J1

J2

J3

J4

42

42

41

41

39

39

40

40

Primary circuit

protection

External

protection

power

Power

3x380-

400VAC

50-60Hz

Transformer

Prim: 400V

Sec: 230V

f: 50/60Hz

S=100VA

ALL WORKS CONCERNED WITH ELECTRICAL INSTALLATION MUST BE CARRIED OUT BY A SKILLED AND QUALIFIED PERSONNEL

The neutral is not earthed. In this case, we advocate the installation of a transformer

L2

L1

N

L3

L

PE

ELMC 5

to 90

WITH NEUTRAL « I T »

External

protection

power

Power

3 x-XXX

VAC

50-60Hz

L2

L1

N

L3

L

PE

ELMC 5

to 90

F2: 2A

F1

T

T: Transformer

Prim: XXXV

Sec: 230V

f: 50/60Hz

S=100VA