ElectroVap MC

EG/HG commissioning

Software assistant

30

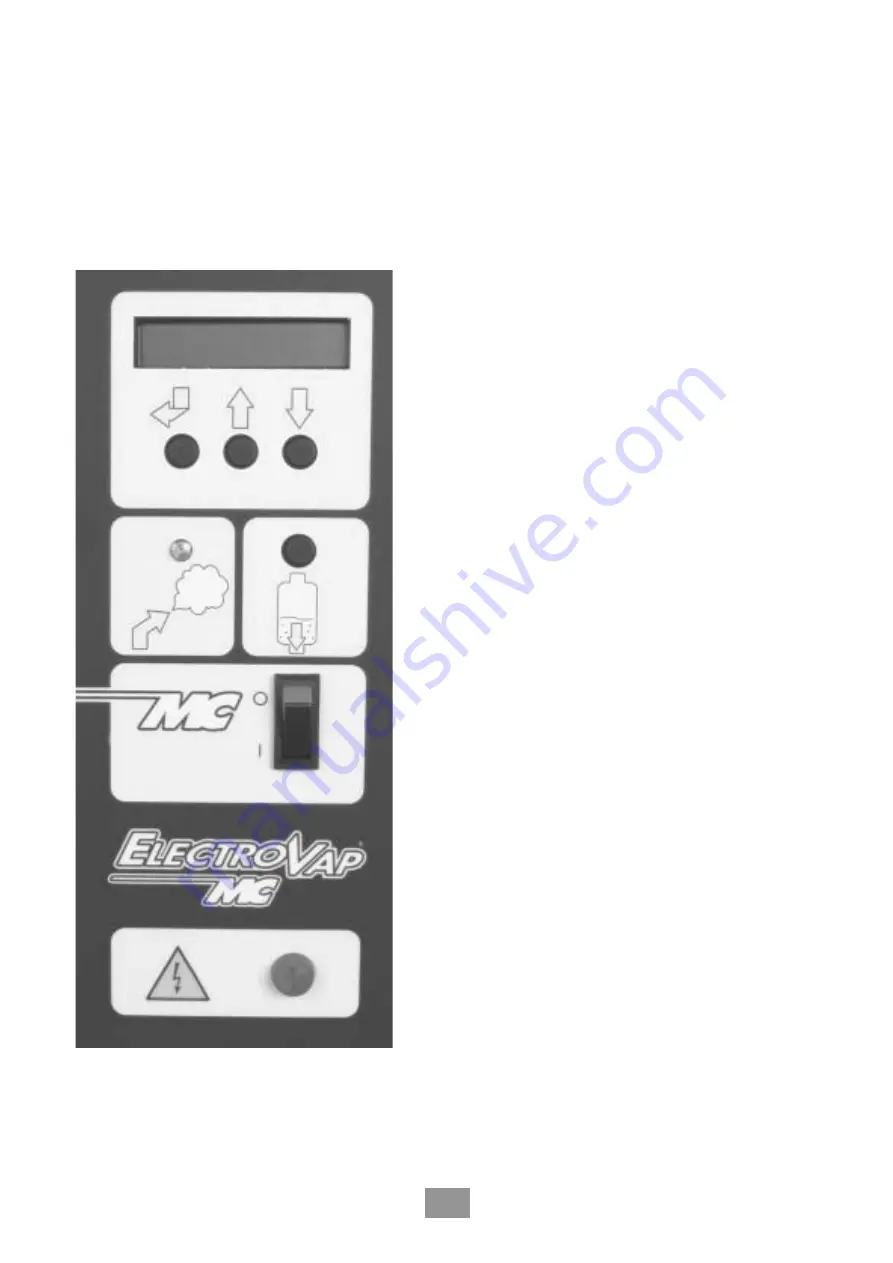

Checking and Switching on

.

1

- After completion of the installation inspection,

switch on the water supply to the unit..

2

- Switch on the main power supply.

3

- The power lamp must be illuminated.

4

- Switch on the main power supply I/0 on I.

The display will default to show the rate of steam

produced.

The steam bath unit offers 3 main menus:

USER INFORMATION

The User Information menu (steam generator

status) provides information on the operation

status of the unit. No parameter can be changed

from within this menu.

HUMIDIFIER CONDITION

(Steam Generator Configuration) menu provides

information only regarding the unit set up. No

parameters can be changed from within this

menu.

CHANGING PARAMETER

The changing parameter System menu

allows all operating parameters to be

adjusted. An access code is required to gain

entry (2 3 4).