ElectroVap RTH-V2

23

Pictures and values are not contractual - The devices may be subject to changes without notice

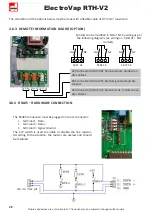

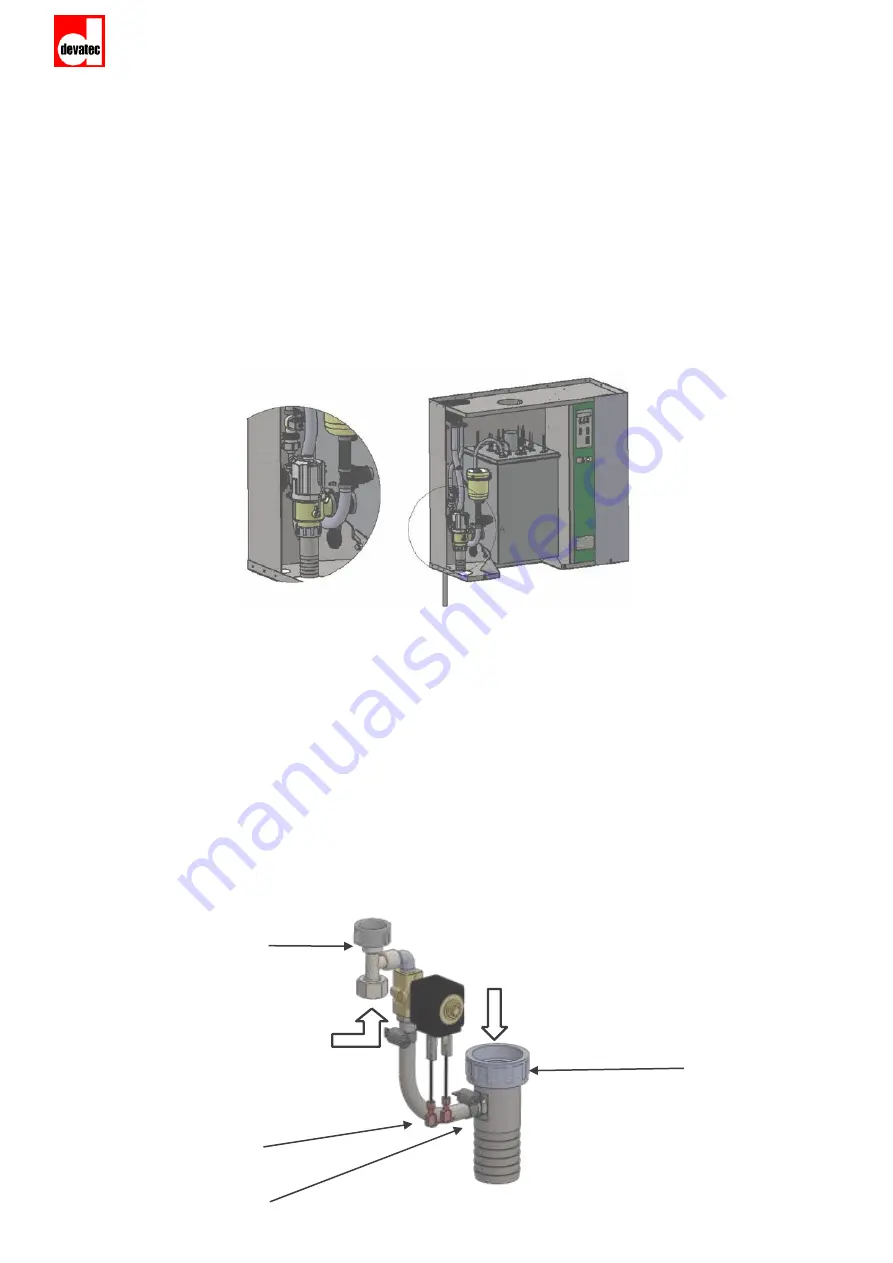

3.7 WATER COOLING KIT OPTION

3.7.1 Functioning

This equipment cools the humidifier's drain water and provides an outlet temperature below 65°C with a

supply water of 15 ° C at a distance of 1 m after the cooling kit.

Each time the humidifier is drained, the valve (7) of the cooling kit opens, and cold water is injected into the

tube (11), allowing the drain water to cool.

3.7.2 Installation

The water cooling kit option it is installed on the water inlet valve through a 3/4’’ plastic connection (4), while

the other side is installed on the drain valve through a 1’’ 1/2 plastic connection (12), the electrical connection

for the valve (7). The cooling inlet valve is electrically supplied by connection to the drain valve coil.

THIS OPTION CAN BE ADDED TO AN EXISTING INSTALLATION.

Option—Drain water cooling kit (ref: 311800540)

Humidifier drain valve outlet

Cold water inlet

4

7

11

12

Summary of Contents for ElectroVap

Page 1: ...RESISTIVE STEAM HUMIDIFIER RTH 5 to 50 kg h TECHNICAL MANUAL ...

Page 2: ......

Page 30: ......