S-9

4.

SERVICE MODE

• This mode is used to check, specify, adjust and register service functions.

4-1.

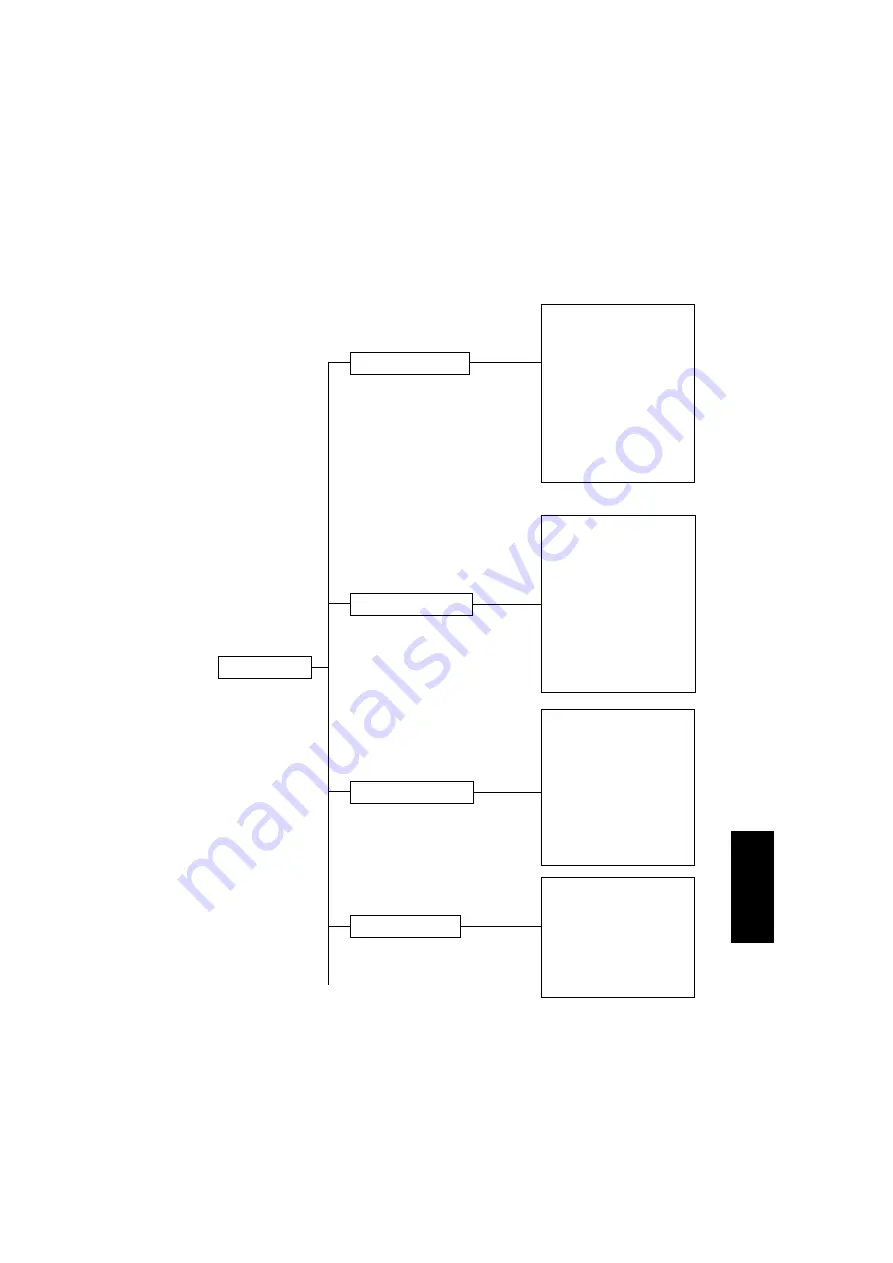

Service Mode Function Tree

Service Mode

Service’s Choice

SHIPMENT DESTINATION

LEADING EDGE ERASE

TRAILING EDGE ERASE

VERTICAL EDGE ERASE

FLS PAPER SIZE

GDI TIMEOUT

TONER EMPTY STOP

PRE-ROTATION

FUSER TEMP.Ad

PRN MAIN REGIST

PRN SUB REGIST

CCD MAIN ZOOM

CCD SUB ZOOM

CCD MAIN REGIST

CCD SUB REGIST

ADF SUB ZOOM

ADF MAIN REGIST

ADF SUB REGIST

ADJUST

COUNTER

DISPLAY

TOTAL COUNTER

PM COUNTER

I/C COUNTER

APPLICATION COUNTER

SCAN COUNTER

PRINTER JAM COUNTER

ADF JAM COUNTER

TROUBLE COUNTER

~

MAIN F/W VER.

ENGINE F/W VER.

MAIN RAM SIZE

SERIAL NO.

CUSTOMER ID

TC TYPE

Summary of Contents for D 16G

Page 1: ...DEVELOP SERVICE MANUAL OPTIONS D 16G 4986 7991 00 ...

Page 2: ......

Page 4: ......

Page 10: ......

Page 11: ...GENERAL ...

Page 12: ......

Page 20: ......

Page 21: ...MECHANICAL ELECTRICAL ...

Page 22: ......

Page 54: ......

Page 55: ...MAINTENANCE ...

Page 56: ......

Page 66: ......

Page 67: ...DIS REASSEMBLY ADJUSTMENT ...

Page 68: ......

Page 116: ......

Page 117: ...CONTROL PANEL SERVICE MODE DESCRIPTIONS ...

Page 118: ......

Page 122: ...S 4 2 3 PWB IF Interface Board 4980S004AA USB port IEEE1284 parallel port ...

Page 142: ......

Page 143: ...TROUBLESHOOTING ...

Page 144: ......

Page 184: ...DEVELOP Copyright 2003 Develop Printed in Germany ...

Page 185: ...AF 11 Service Manual ...

Page 188: ...GENERAL ...

Page 190: ...MECHANICAL ELECTRICAL ...

Page 199: ...DIS REASSEMBLY ADJUSTMENT ...

Page 215: ...TROUBLESHOOTING ...

Page 224: ...PF 125 Service Manual ...

Page 226: ...GENERAL ...

Page 228: ...MECHANICAL ELECTRICAL ...

Page 233: ...DIS REASSEMBLY ADJUSTMENT ...