4 — ENG

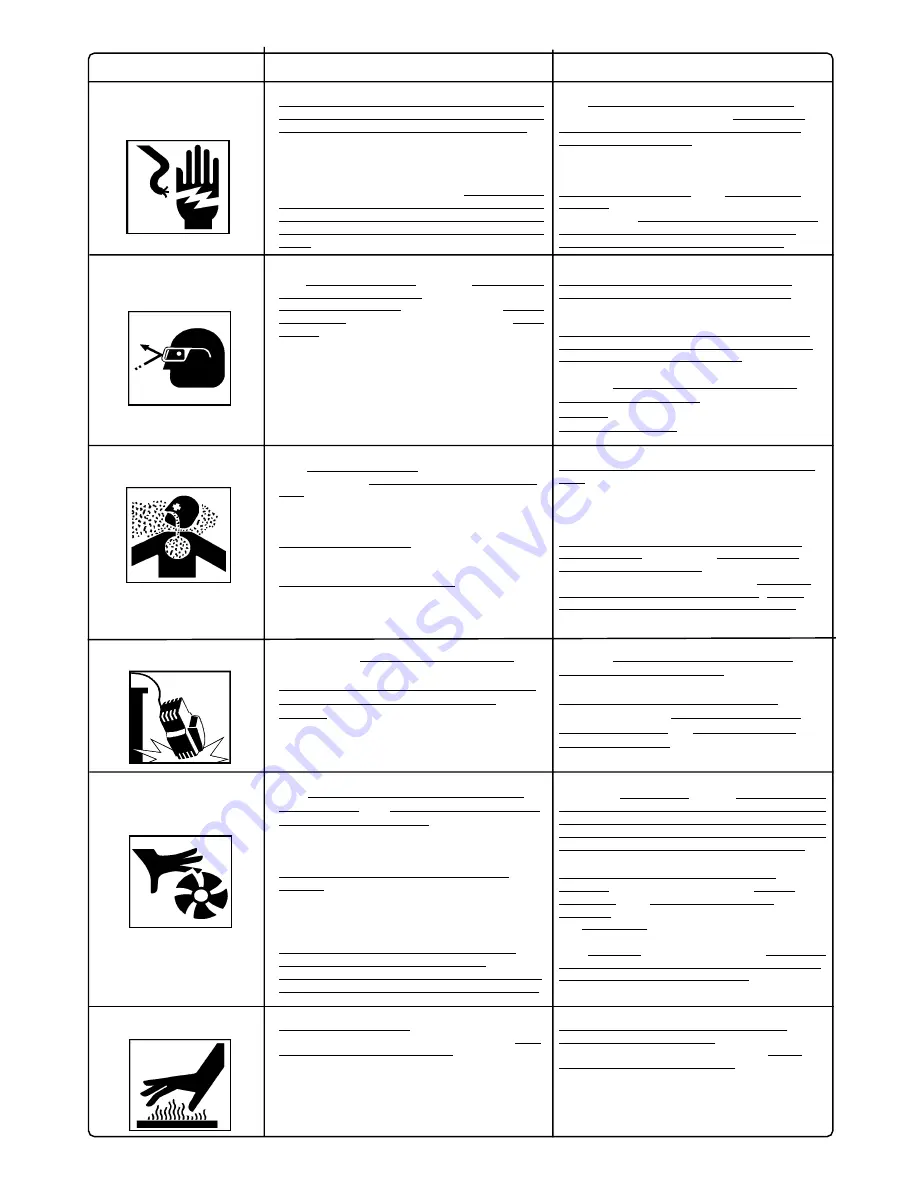

HAZARD

RISK OF ELECTRICAL

SHOCK (cont’d)

RISK FROM

FLYING OBJECTS

RISK TO BREATHING

RISK OF FALLING

RISK FROM

MOVING PARTS

RISK OF BURNS

WHAT CAN HAPPEN

REPAIRS ATTEMPTED BY UNQUALIFIED

PERSONNEL CAN RESULT IN SERIOUS

INJURY OR DEATH BY ELECTROCUTION.

ELECTRICAL GROUNDING:

FAILURE TO

PROVIDE ADEQUATE GROUNDING TO THIS

PRODUCT COULD RESULT IN SERIOUS

INJURY OR DEATH FROM ELECTROCU-

TION.

SEE GROUNDING INSTRUCTIONS.

THE

COMPRESSED AIR

STREAM

CAN CAUSE

SOFT TISSUE DAMAGE

TO EXPOSED SKIN

AND CAN PROPEL

DIRT, CHIPS,

LOOSE

PARTICLES

AND SMALL OBJECTS AT

HIGH

SPEED

, RESULTING IN PROPERTY DAMAGE

OR PERSONAL INJURY.

THE

COMPRESSED AIR

FROM YOUR

COMPRESSOR

IS NOT SAFE FOR BREATH-

ING!

THE AIR STREAM MAY CONTAIN

CARBON MONOXIDE, TOXIC VAPORS OR

SOLID PARTICLES.

SPRAYED MATERIALS

SUCH AS PAINT,

PAINT SOLVENTS, PAINT REMOVER,

INSECTICIDES, WEED KILLERS, ETC..

CONTAIN HARMFUL VAPORS

AND POI-

SONS.

A PORTABLE

COMPRESSOR CAN FALL

FROM A TABLE, WORKBENCH OR ROOF

CAUSING DAMAGE TO THE COMPRESSOR

WHICH COULD RESULT IN SERIOUS

INJURY.

THE

COMPRESSOR CYCLES AUTOMATI-

CALLY WHEN

THE

PRESSURE SWITCH IS IN

THE ON/AUTO POSITION

MOVING PARTS CAN CAUSE SERIOUS

INJURY

OR DAMAGE IF THEY COME INTO

CONTACT WITH YOU OR YOUR CLOTHING.

ATTEMPTING TO OPERATE OR REPAIR

COMPRESSOR WITH PROTECTIVE

SHROUDS REMOVED CAN EXPOSE YOU TO

MOVING PARTS AND ELECTRICAL SHOCK.

TOUCHING EXPOSED

METAL SUCH AS THE

COMPRESSOR HEAD OR OUTLET TUBE

CAN

RESULT IN SERIOUS BURNS.

HOW TO PREVENT IT

ANY

ELECTRICAL WIRING OR REPAIRS

REQUIRE ON THIS PRODUCT

SHOULD BE

PERFORMED BY AUTHORIZED SERVICE

CENTER PERSONNEL.

IN ACCORDANCE

WITH NATIONAL AND LOCAL ELECTRICAL

CODES.

MAKE CERTAIN THAT

THE

ELECTRICAL

CIRCUIT

TO WHICH THE COMPRESSOR IS

CONNECTED

PROVIDES PROPER ELECTRI-

CAL GROUNDING, CORRECT VOLTAGE

AND ADEQUATE FUSE PROTECTION.

ALWAYS WEAR ANSI Z87.1 APPROVED

SAFETY GLASSES WITH SIDE SHIELDS

WHEN USING THE COMPRESSOR.

NEVER POINT ANY NOZZLE OR SPRAYER

TOWARD ANY PART OF THE BODY OR AT

OTHER PEOPLE OR ANIMALS.

ALWAYS

TURN THE COMPRESSOR OFF

AND BLEED PRESSURE

FROM THE AIR LINE

BEFORE

ATTEMPTING MAINTENANCE,

ATTACHING TOOLS

OR ACCESSORIES.

NEVER INHALE AIR FROM THE COMPRES-

SOR

EITHER DIRECTLY OR FROM A BREATH-

ING DEVICE CONNECTED TO THE COMPRES-

SOR.

WORK IN AN AREA WITH GOOD CROSS-

VENTILATION.

READ AND

FOLLOW THE

SAFETY INSTRUCTIONS

PROVIDED ON THE

LABEL OR SAFETY DATA SHEETS

FOR THE

MATERIAL YOU ARE SPRAYING.

USE A

NIOSH/MSHA APPROVED RESPIRATOR

DESIGNED FOR USE WITH YOUR SPECIFIC

APPLICATION.

ALWAYS

OPERATE COMPRESSOR IN A

STABLE SECURE POSITION

TO PREVENT

ACCIDENTAL MOVEMENT OF THE UNIT.

NEVER OPERATE COMPRESSOR ON A

ROOF OR OTHER ELEVATED POSITION.

USE ADDITIONAL AIR HOSE TO REACH

HIGH LOCATIONS.

ALWAYS

TURN OFF

THE

COMPRESSOR,

BLEED PRESSURE FROM THE AIR HOSE,

AND UNPLUG FROM ELECTRICAL OUTLET

BEFORE PERFORMING MAINTENANCE OR

ATTACHING TOOLS AND ACCESSORIES.

DO NOT REMOVE THE PROTECTIVE

COVERS

FROM THIS PRODUCT.

NEVER

OPERATE

THE

COMPRESSOR WITH

GUARDS

OR COVERS WHICH ARE DAMAGED

OR

REMOVED.

ANY

REPAIRS

REQUIRED ON THIS

PRODUCT

SHOULD BE PERFORMED BY AUTHORIZED

SERVICE CENTER PERSONNEL.

NEVER TOUCH ANY EXPOSED METAL

PARTS ON COMPRESSOR

DURING OR

IMMEDIATELY AFTER OPERATION.

COM-

PRESSOR WILL REMAIN HOT

FOR SEVERAL

MINUTES AFTER OPERATION.

TMPCPOL — 3/11/97