6

© 2012 Finishing Brands UK Ltd.

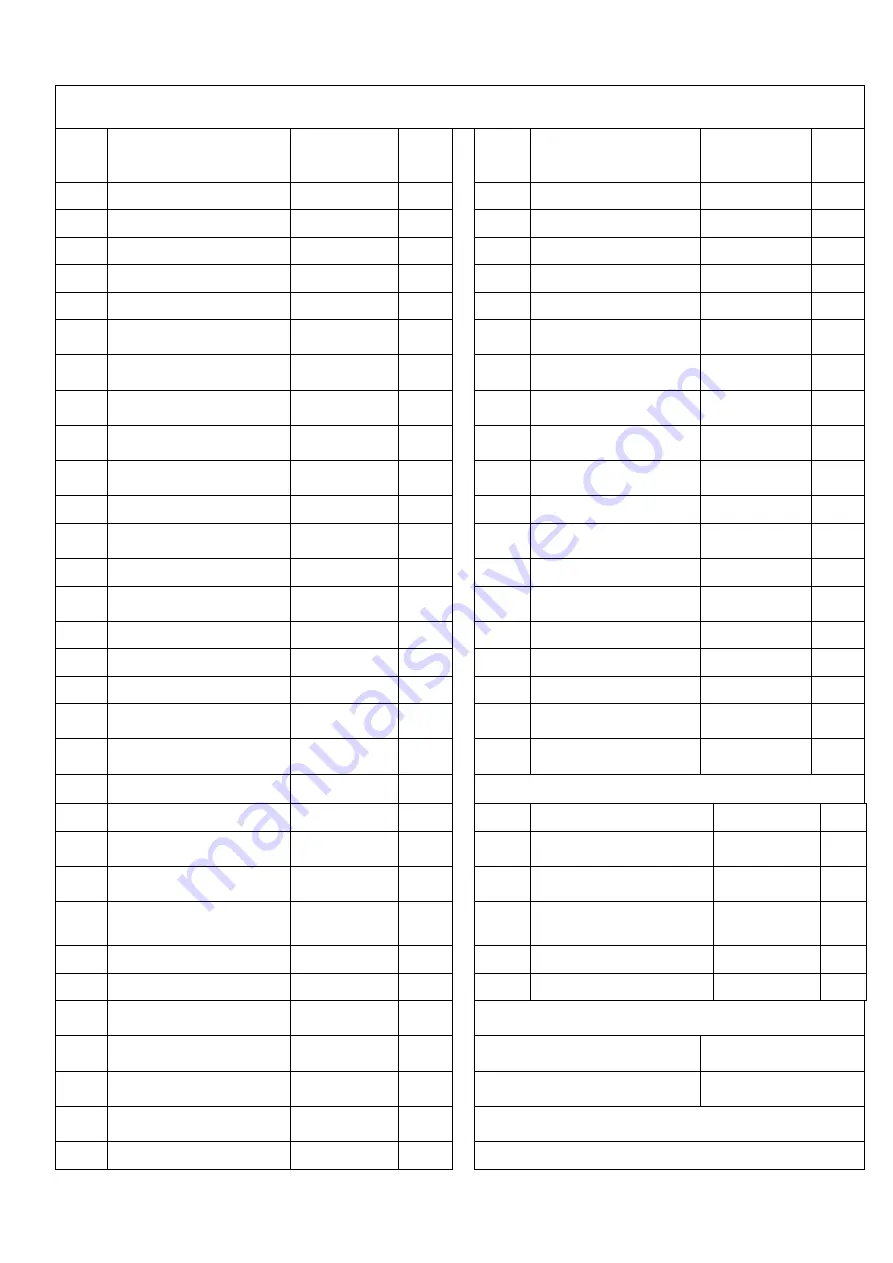

PARTS LIST

REF.

NO.

DESCRIPTION

PART NO.

QTY

REF.

NO.

DESCRIPTION

PART NO.

QTY

1

Air Cap Retaining Ring

-

1

32

Air Valve Poppet

-

1

2

Slip Ring

-

1

33

Air Valve Spring

-

1

3

Air Cap

-

1

34

Air Valve Spring Pad

-

1

4

Air Cap Retaining Clip

JGA-156-K5

1

35

Air Valve Seal

SN-34-K5

1

5

Retaining Ring Seal

-

1

36

Air Valve Assembly

SN-402-K

1

6

Aircap & Ring

See chart 1

p14

1

*37

Trigger Stud Screw

(T20 TORX)

-

1

7

Air Cap Retaining Ring &

Seals

ADV-403-K

1

38

Trigger

-

1

8

Fluid Nozzle

See chart 2

p14

1

*39

Trigger Stud

-

1

9

Separator

SP-626-K5

1

40

Trigger, Stud & Screw

Kit

SN-63-K

1

10

Fluid Nozzle Kit

See chart 2

p14

1

41

Spanner

-

1

*12

Body Bushing Seal

-

1

42

Air Inlet

SN-9-K

1

13

Body Bushing

-

1

43

Colour ID Ring Kit (4

Colours)

SN-26-K4

1

14

Body Bushing & Seal

SN-6-K

1

45

Stud and Screw kit

SN-405-K5

1

15

Fluid Needle

See chart 2

p14

1

46

Air valve Service Tool

-

1

*16

Needle Spring

-

1

47

Torx Key

SPN-8-K2

1

*17

Needle Spring Pad

-

1

54

Fluid Inlet Connector

-

1

18

Fluid Adjusting Knob

-

1

55

Lock Nut

-

1

19

Fluid Adjusting Knob,

Spring & Pad Kit

ADV-6-K

1

56

Seal

-

1

*20

Retaining Clip

-

2

57

Fluid Inlet Connector

Kit

ADV-7-K

1

21

Spreader Valve Body

-

2

Suction Cup Models only

*22

Spreader Valve Seal

-

2

58

Suction Cup

KR-566-1-B

1

23

Spreader Valve

Adjusting Knob

-

2

59

Cup Lid Gasket - kit of 3

KR-11-K3

1

*24

Spreader Valve Pin

-

2

60

Drip Check Diaphragm-

Kit of 5

KR-115-K5

1

25

Spreader & Airflow Valve

Assembly

ADV-401-K

2

61

Filter

– Kit of 10

KR-484-K10

1

*26

Needle Packing

-

1

62

Lid Assembly

KR-4001-B

1

*27

Packing Spring

-

1

63

Cup

KR-466-K

1

*28

Packing Nut

-

1

SERVICE PARTS

29

Packing, Spring &

Packing Nut Kit

SN-404-K

1

Spray Gun repair kit (includes

items marked *)

PRO-415-1

+29a Ceramic packing

ADV-406-K2

1

Seal and Pin Kit, kit of 5 (items

20, 22 and 24)

GTI-428-K5

30

Air Valve Body

-

1

+ Optional packing for ceramic applications included in

470 Aircap models only.

31

Air Valve Cage

-

1

For accessories, see page 17