CONDITION

CONDITION

CAUSE

CORRECTION

A

1. No pressure at the gun.

1. Check air and coating material lines.

2. Gun passages blocked.

2. Clean.

B & C

1. Coating material build-up on air

1. Clean air cap or nozzle.

cap or nozzle.

D

1. Coating material too thick or too much.

1. Thin or reduce coating material flow.

E

1. Not enough coating material.

1. Reduce atomising air pressure or

increase coating material flow.

F

1. Insufficient material in tank, cup or

1. Fill tank/cup, or clear obstruction.

an obstruction in the hose.

2. Gun material passage blocked.

2. Clean.

3. Worn seal (4).

3. Replace.

4. Loose or damaged nozzle.

4. Tighten or replace.

G

1. Incorrect air pressure on diaphragm

1. Increase air pressure to at leased

0.5 bar (8 lbf/in

2

) above coating

material pressure.

2. Seat (5) dirty or worn.

2. Clean or replace.

3. Damaged or worn diaphragm (6).

3. Replace.

4. Air leak from valve (13).

1. Replace ‘0’ ring (12).

SERVICE CHECKS

SB-E-2 -660 – © ITW LTD 1994

7

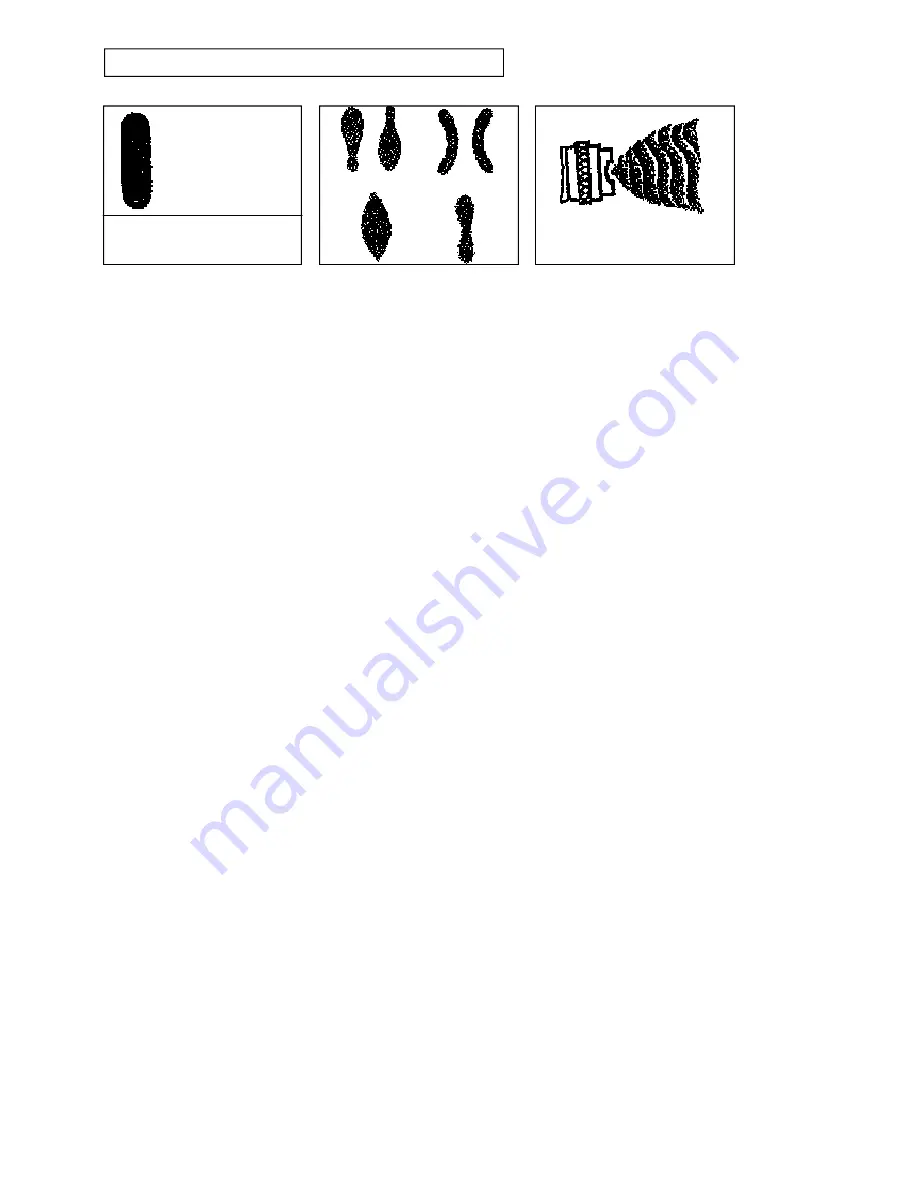

NORMAL SPRAY PATTERN

A

Will not spray

B

C

D

E

G

Dripping from nozzle (2)

F

Fluttering Spray