7 — ENG

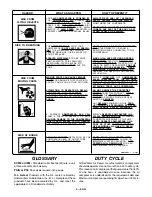

Air Hose

The air hose attached to your compressor has an integral

pressure adjusting valve at the working end of the hose.

Should service or replacement be required, make sure that

the pressure adjusting valve is present in the air hose line.

It is normal for the adjustable pressure valve to release air

during operation.

Do not modify the plug that has been provided. If it

does not fit the available outlet, the correct outlet

should be installed by a qualified electrician.

If repairing or replacing cord or plug, the grounding

wire must be kept separate from the current-carrying

wires. Never connect the grounding wire to a flat blade

plug terminal. The grounding wire has insulation with

an outer surface that is green - with or without yellow

stripes.

If these grounding instructions are not completely

understood, or if in doubt as to whether the compres

sor is properly grounded, have the installation checked

by a qualified electrician.

Do not allow hose to become kinked or pinched at

any time. This is important to avoid damage to your

compressor and to maintain pressure adjusting valve

control.

120 Volts, 15 Amps

120 Volt Models

Compressed air from the outfit may contain water

condensation. Do not spray unfiltered air at an item

that could be damaged by moisture. Some air

operated tools or devices may require filtered air.

Read the instructions for the air tool or device.

1. Before plugging in the air compressor, set the adjust-

able pressure valve to "10" PSI. Make sure the "ON/

OFF" switch is in the "OFF" position.

2. Connect the air tool or accessory to the air hose.

Tighten securely.

3. Plug the power cord into the grounded outlet.

4. Start the compressor by setting the "ON/OFF" switch

to the "ON" position.

5. Check the manufacturer's maximum pressure rating

for the air tool, accessory or vehicle tire being used.

The air compressor outlet pressure must never exceed

the maximum pressure rating.

6. Slowly increase the pressure setting of the adjustable

pressure valve. You should be able to hear and feel air

pressure being relieved by the adjustable pressure

valve. If pressure is not being relieved, turn the air

compressor off immediately. The pressure valve must

be replaced.

OPERATING PROCEDURES

INSTALLATION AND BREAK-IN PROCEDURES

DO

NOT

REPLACE THE HOSE WITH STANDARD

HOSE THAT IS NOT EQUIPPED WITH THE PRES-

SURE ADJUSTING VALVE. THE APPROPRIATE

HOSE ASSEMBLY FOR YOUR COMPRESSOR IS

AVAILABLE AT SEARS.

TOO MUCH AIR PRESSURE COULD CAUSE AN

AIR TOOL OR VEHICLE TIRE TO RUPTURE OR

EXPLODE. CAREFULLY FOLLOW STEPS 5 AND 6

EACH TIME YOU USE YOUR COMPRESSOR.

Summary of Contents for FA100

Page 11: ...11 ENG SERVICE NOTES...