SB-2-199-F Page 3

PARTS REPLACEMENT

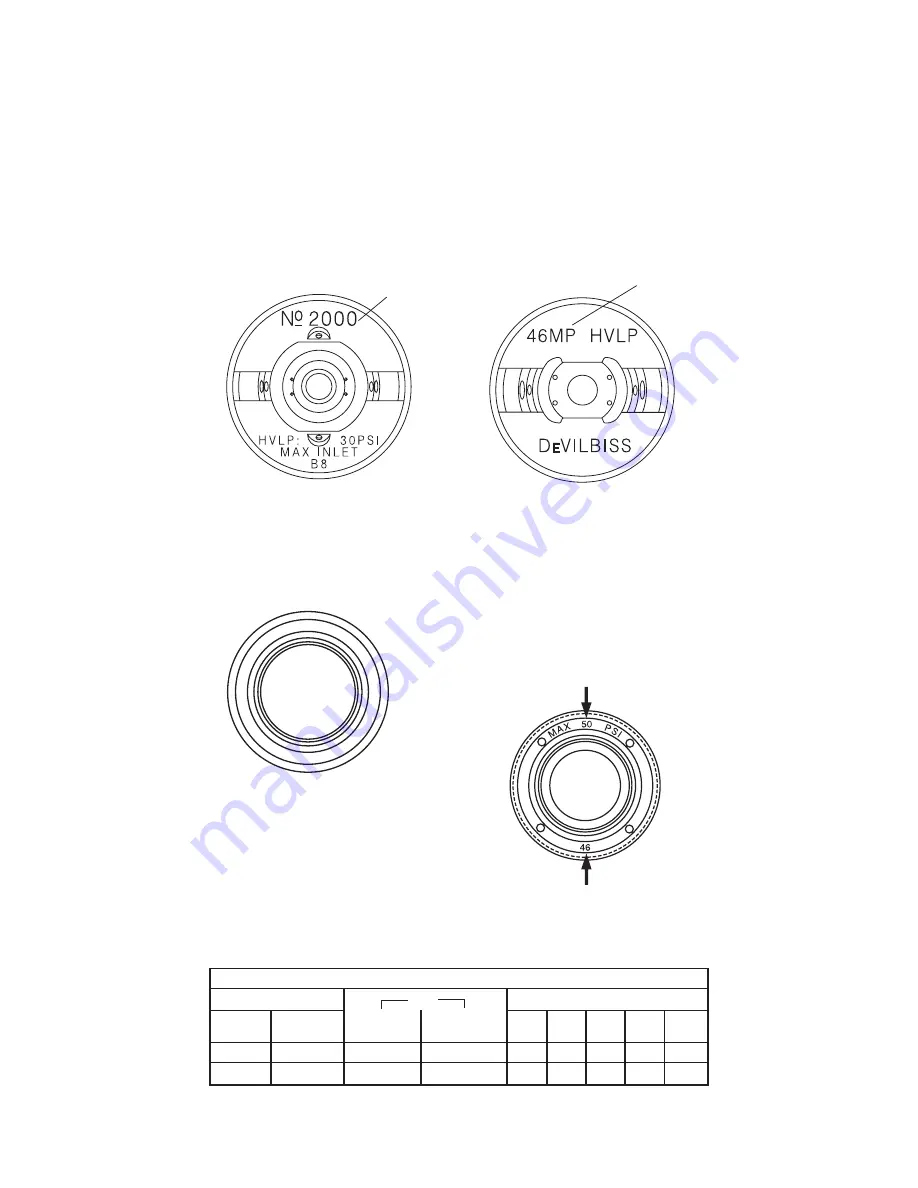

Figure 1 Air Cap and Baffle Identification

NOTE:

The baffle is specially designed to

give the required performance for the

correct air cap. Use of incorrect baffle

and air cap will result in substandard

performance and/or improper air cap

pressures. (See Chart 1 for ordering

correct baffle.)

Air Cap No.

Maximum air pressure required to

assure compliance of 10 PSI max. cap

pressure – this reading must be taken at

the spray gun handle inlet fitting.

No. 2000 Air Cap

No. 46MP Air Cap

Air Cap No.

The 46MP Air Cap doesn't have mark-

ings showing the maximum air pressure

required to assure compliance of 10

PSI max. cap pressure. That value is

located on the front of the baffle. (See

view below.)

NOTE:

The baffle used with the #2000 cap

doesn't have any markings on it. The

maximum air pressure required to

assure compliance of 10 PSI max. cap

pressure is located on the face of the

air cap. (See view above.)

Baffle for #2000 Air Cap

Baffle for #46MP Air Cap

Air cap number located on face of cap.

Cap number must correspond with

baffle number to assure 10 PSI cap

pressure.

Maximum air pressure required to

assure compliance of 10 PSI max. cap

pressure – this reading must be taken

at the spray gun handle inlet fitting.

Chart 1

Air Cap & Baffle Combinations

No. Stamped on Parts

Set

CFM@ Cap Pressure

Air Cap

Ref. No. 4

Ref. No. 6

Part No.

Baffle

Air Cap

Baffle Assy. 2 psi 4 psi 6 psi 8 psi 10 psi

2000

(Not Stamped)

GTI-407-2000

GTI-425 7.3 10.4 12.8 14.7 16.5

46MP

46

GTI-407-46MP *JGPV-401-46-50 8.5 13.0 16.5 19.8 22.5

*Note: Baffle seal not used with JGPV-401-46-50 baffle.