14

© 2013 Finishing Brands UK Ltd.

Troubleshooting Possible Problems in Operation

²³´µ¶ ·

¶ ³´

² ¸¹º»

²³¼¼»

²

·

¶ ³´

R

bottom

Heavy

C '

"

$

pattern

R

'

"

$

"

C C

O

Obstruction on top or bottom of

"

nozzle.

Cap and

/ /"

$

O

Left or right side horn holes plugged.

Dirt on left or right side of fluid

//"

O

"

O

-

%

'

-metallic

point.

Clean.

Clean.

Clean. Ream with non

¢

metallic

O

Clean.

½¾ ½¿ À½ Á

à Ä

ÅÆ ½

Å Ã

Ç

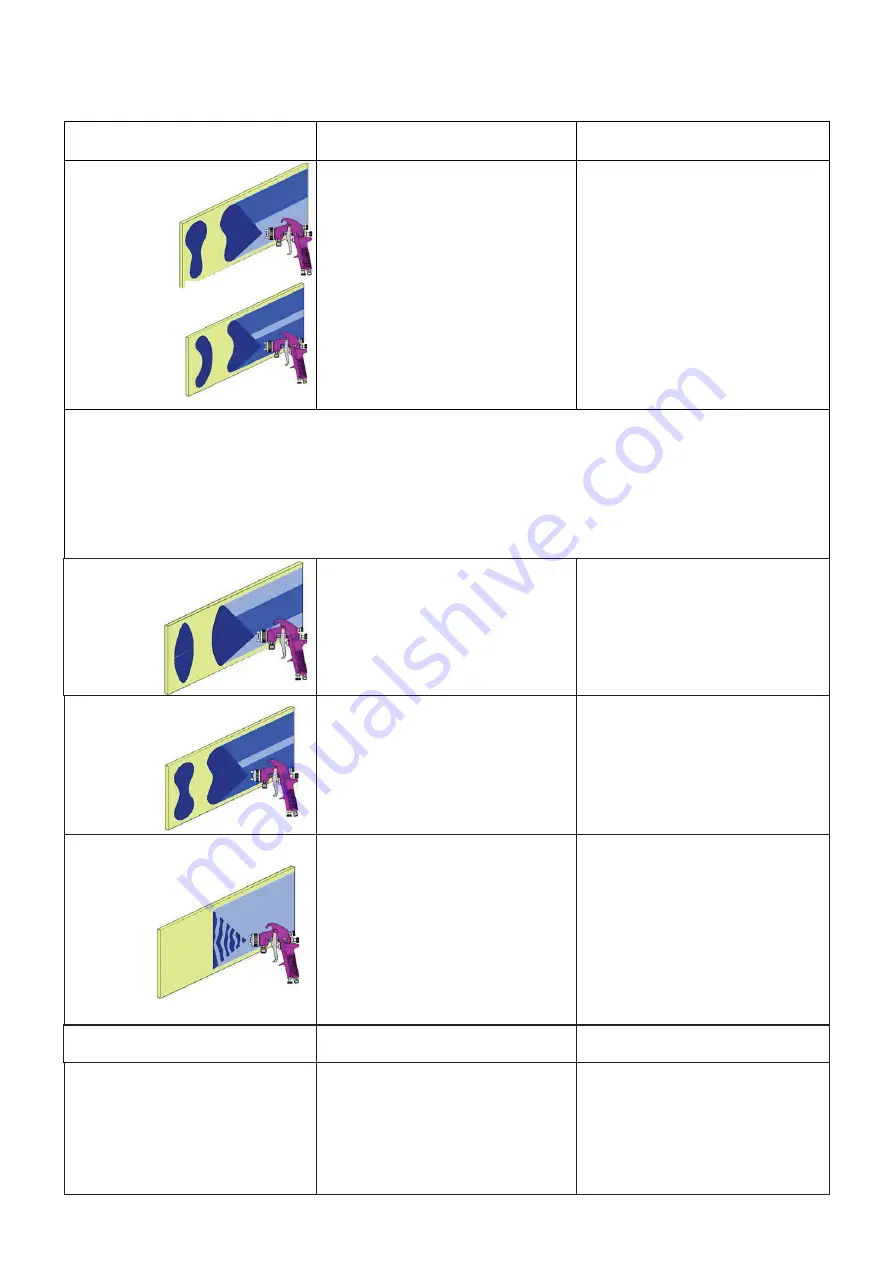

-heavy, bottom-heavy, right-heavy, and left-heavy patterns:

1. Determine if the obstruction is on the air cap or the

"

nozzle. Do this by making a test spray pattern.

T

'

7

rotate the cap one

¢

half turn and spray another pattern. If the defect is inverted, obstruction is on the air cap.

"

'

$

$

"

$

O

"

$

'

A

F

$

$

'

hole opening;

#

washing with solvent.

2. If the defect is not inverted, it is on the

"

nozzle. Clean nozzle. If problem persists, renew nozzle.

R

centre

S

F

$

"

$

too

low.

Atomising pressure too low.

Material too thick.

T

"

A

%

$

a

'

correct pattern.

Increase pressure.

Thin to correct consistency.

S "

$

patter

ir pressure too high.

Fluid adjusting knob turned in

far.

Spreader adjusting valve set too

'

C

'

O

-

C

"

C

'

"

O

Turn out counter clockwise to

'

correct pattern.

Turn in clockwise to achieve

correct pattern.

¤

A

or fluttering spray

; $

C

fluid nozzle/seat

Loose or broken cup

"

nipple

N

"

"

"

"

%

§#$

"

passage

; $

"

needle packing nut

0

C

"

needle packing

T

C '

"

Tighten or replace cup

-

"

l

R

"

C '

&

A

"

$

'

with solvent

T

C '

-

"

6

# ## "

$

"

/ /"

C '

O

T

C '

1 4

–

20 nm (13-15 ft-

"

#$

O

"

"

A

C

C

lid

"

"

$

O

Dirty cup

"

O

Cracked cup or lid.

6

$

'

"

O

Clean.

Replace cup and lid.