© 2005 ITW Finishing Systems and Products

8

clean and free from damage. Build

up of dried paint can distort the

spray pattern.

6. Lubrication – stud/screw (6), needle

(9) and air valve (11) should be

oiled each day.

Replacement of Parts

E

E

Nozzle (2) and Needle (9) –

Remove

parts in the following order: 7, 8, 9, 1

and 2. Replace any worn or damaged

parts and re-assemble in reverse order.

Recommended tightening torque for

nozzle (2) 9.5-12 Nm (80-100 lbf in).

Packing –

Remove parts 7, 8, 9.

Unscrew cartridge (4). Fit new cartridge

finger tight. Re-assemble parts 9, 8,

and 7 and tighten cartridge (4) with

spanner sufficient to seal but to allow

free movement of needle. Lubricate

with gun oil.

Air Valve Seal Kit (16) - (Refer to

photos 1 to 28 and fig 2)

1. Remove Adjusting Knob (7), Spring

(8), and Needle (9).

2. Loosen Housing (10).

3. Remove Housing (10) and Airvalve

Spring.

4. Remove Valve (11).

5. Using Service Tool SPN-7, engage

groove behind the Valve Seat.

6. Remove Valve Seat.

7. Push out the Front Airvalve Seal

with a finger.

8. Turn the Gun upside down and let

the Seal fall out.

9. Fit New Front Seal to Service Tool.

10. Fit new Seal to gunbody and press

firmly to ensure Seal is engaged.

11. Fit New Valve Seat to Service Tool.

Groove must face outwards.

12. Fit Valve Seat to Gunbody.

13. Remove Rear Airvalve Seal from

housing (10) with a hooked

instrument.

14. Fit new Seal to Service Tool.

15. Fit Seal to Housing (10).

16. Replace Valve (11).

17. Replace Valve Spring and screw in

Housing (10).

18. Tighten Housing.

19. Fit Needle (9).

20. Fit Spring (8) and Knob (7).

21. Adjust Needle Packing (4) with

Spanner sufficient to seal but to

allow free movement of needle.

Lubricate with gun oil.

Spreader valve (5) – Caution:

always

ensure that the valve is in the fully open

position by turning screw fully counter-

clockwise before fitting to body.

Air cap / Nozzle Selection

Refer to coating material manufacturers

recommendations or ITW Finishing UK

Website:

www.itweuropeanfinishing.com

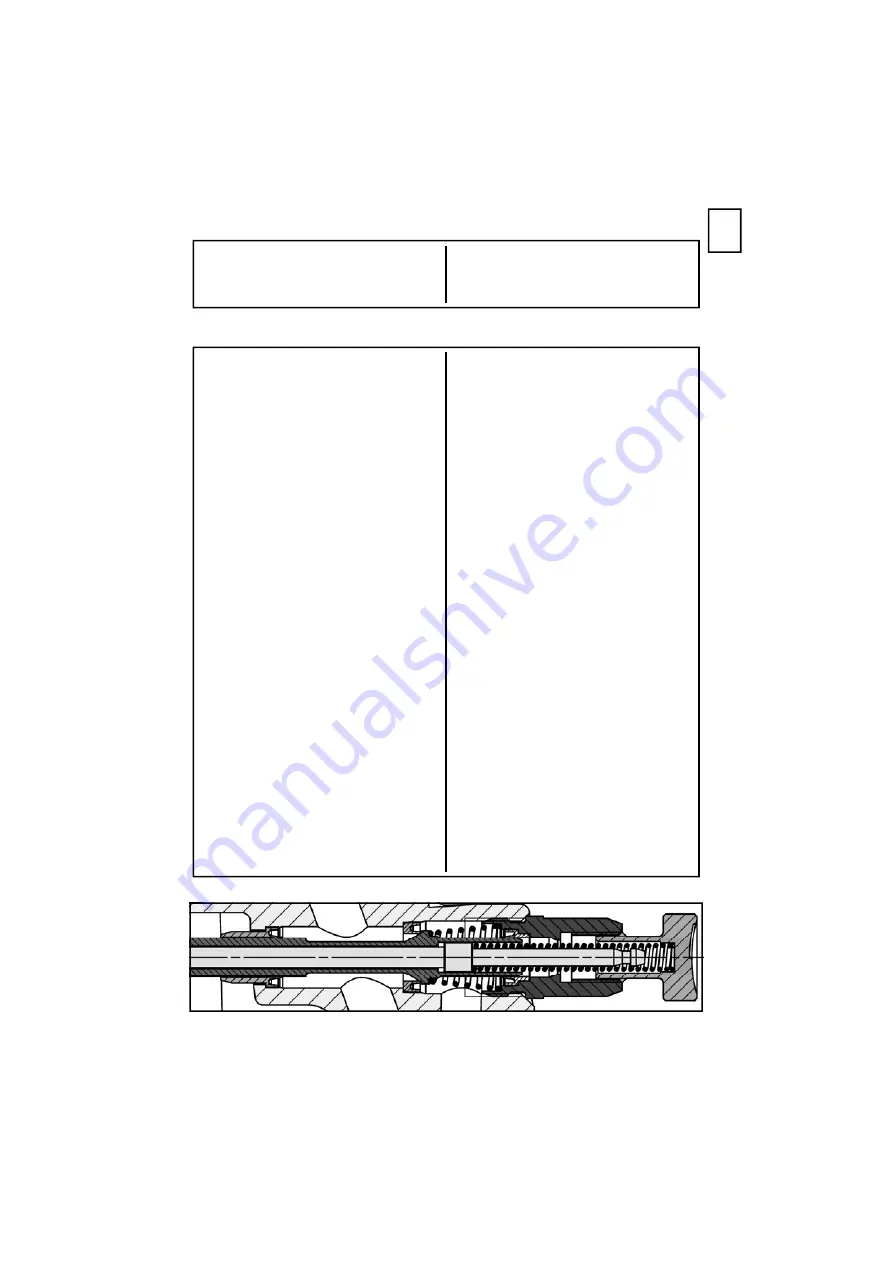

FIG 2