Page 8 SB-2-252-J

6/04

©Copyright 2004, ITW

Printed in U.S.A.

NIOSH-Certified, for

respiratory protection

in atmospheres not

immediately dangerous

to life.

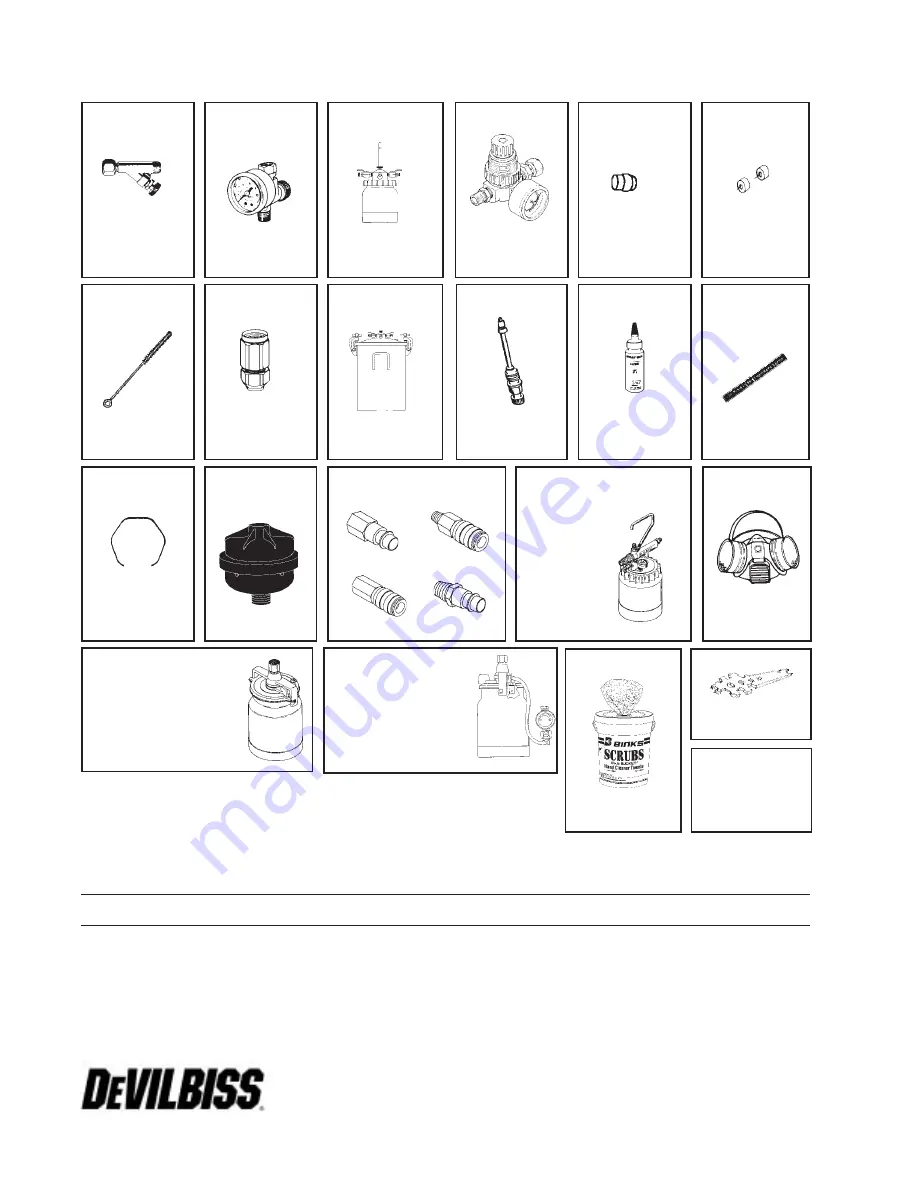

TGC-545 (Aluminum) TLC-555

(Teflon Lined)

TSC-595 S.S. 2 Qt. Drip-Free

Suction Cup

Provides greater

degree of control

over cup fluid

pressure.

Millennium 3000

Twin Cartridge

Paint Spray Respirator

KB-555 (Aluminum) &

KB-545-SS (S/S) 2 qt. Pressure

Feed Cup With Regulator

Cup has a unique, two position

valve which permits selection of

either a drip-free or conventional

open vent mode.

JGA-444 Fluid Tube

This tube combines the

fluid and air hoses at gun

handle preventing drag-

ging hoses over work, twist-

ing line and improving

overall gun handling.

TLC-576 Aluminum Cup

(Teflon Lined) &

TSC-591Stainless Steel Cup

1 Qt. pressure feed cups.

3/8" NPS (F), cam lock lid.

Requires KK-4980 air regulator

kit.

Quick Disconnect Approved for

HVLP Guns (Air)

High Flow Ball and Ring Type

HC-4419 1/4"

NPS(F)

HC-4699

1/4" NPT(M)

HC-1166

1/4" NPT(M)

HC-4700

1/4" NPT(F)

Enables user to control

and reduce air usage at

the gun. Ideal for low

pressure spraying.

P-H-5516 Air

Adjusting Valve

HARG-510 Air

Regulator

Use to maintain nearly

constant outlet pressure

despite changes in inlet

pressure and down-

stream flow.

HD-503

SolventSaver™

Hose/Gun Cleaner

Used when abrasive

materials are sprayed

(i.e. porcelain enamel).

Use (2) JGA-52 packings

in place of JGV-463

packing.

JGA-52-K10

Leather Packings

VS-531 Low

Pressure

Strainers

QMGZ

SolventSaver™

Hose/Gun Cleaner

GTI-415 Air

Adjusting Valve

Installs into gun to en-

able user to control and

reduce air usage at the

gun. Replaces JGA-132

plug.

Spray Gun Lube

SSL-10 (2 oz.

bottle)

Compatible with all

paint materials: con-

tains no silicone or pe-

troleum distillates to

contaminate paint.

MSDS sheet available

upon request.

2 Qt Hose/Gun Cleaner

used to clean the inside

of hose, fluid passage-

ways of gun & other

paint equipment.

The VS-531 Low Pres-

sure Fluid Strainer pro-

vides a final filter for

trapping foreign par-

ticles in the paint sup-

ply.

2 Gallon galvanized tank

used to clean the inside

of hose and material

passages of the gun.

ACCESSORIES

Provides reduced

spring force (4 lbs.

verses 6 lbs.) for easier

trigger pull.

MSA-4-K10 Fluid

Needle Spring

(replaces MBD-19)

Joins any single piece

DeVilbiss air cap MBC-

368 or MSA-1 retaining

ring. Helps prevent

parts loss and provides

easier assembly.

JGA-156-K10

Spring Clip

HAF-507

Whirlwind™

In-Line Air Filter

Removes water, oil, and

debris from the air line.

This 3 piece packing

can be used in place of

Ref. (18) JGV-463, 2

piece packing.

JGA-4035-K5

Optional 3 Piece

Packings

HAV-500 or

HAV-501

Adjusting Valve

(HAV-501 SHOWN)

HAV-500 does not have

pressure gage. Use to

control air usage at gun.

42884-214-K5 3/8"

42884-215-K10 5/8"

Cleaning Brushes

These brushes are help-

ful in cleaning threads

and recesses of gun

body.

WR-103 Wrench

Contains all necessary

tip, hose and nut sizes

used on

or with gun.

Scrubs® are a pre-

moistened hand cleaner

towel for painters.

No water is needed.

29-3100 Scrubs

®

Hand Cleaner Towels

WARRANTY

This product is covered by DeVilbiss' 1 Year Limited Warranty.

DeVilbiss Worldwide Sales and Service Listing: www.devilbiss.com

ITW Industrial Finishing

DeVilbiss has authorized distributors throughout the world. For

technical assistance or the distributor nearest you, see listing below.

U.S./Canada Technical Service Office:

195 Internationale Blvd., Glendale Heights, IL 60139

Toll-Free Telephone: 1-888-992-4657 (U.S.A. and Canada only)

Toll-Free Fax: 1-800-368-8401