4

© 2007 ITW Finishing Systems and Products

Parts List

Ref. No

Description

Part Number

Qty

1

Air Cap/Retaining ring

See Chart 2

1

1a

Spring Clip - Kit of 5

JGA-156-K5

1

+2

Nozzle

See Chart 3

1

3

Seal

JGD-402-K

1

+3a

Baffle seal—Kit of 5

GTI-33-K5

1

+4

Spring Adjusted Needle Packing

GTI-445-K2

1

5

Spreader Valve

GTI-405-K

1

6

Stud and Screw - Kit of 5

GTI-408-K5

1

+7

Needle

See Chart 3

1

+8

Spring - Kit of 5

GTI-409-K5

1

9

Bushing

JGA-17

1

10

Needle Adjusting Screw

GTI-414-K

1

11

Valve Assembly

JGK-449

1

12

Trigger

GTI-108

1

13

Connector

JGA-158

1

14

Airflow Valve

GTI-415-K

1

15

Lock Nut - Kit of 5

JGA-51-K5

1

16

Seal

23165-001

1

17

Fluid Inlet Connector and seal Kit

JGA-159-K

1

18

Seal + Pin kit ( + SST-8434-K5)

GTI-428-K5

2

19

Circlip - Kit of 5

2

20

Circlip - Kit of 5

25746-007-K5

1

+21

Seal - Kit of 5

JGS-72-K5

2

22

Air valve stem assembly

1

23

Spring

JGV-262-K5

1

+ -

Parts included in service Kit KK-4502 (see accessories)

E

E

No

Order No.

G

0.7

FX

1.1

FZ

1.2

FF

1.4

FW

1.6

EE

1.8

EX

1.8

DE

2.0

D

2.2

AC

2.8

Air-

flow

Pressure

bar

30+ AV-4239-30

9

9

9

301

3.0

43

AV-4239-43

9

9

307

3.0

62

MB-4039-62

9

449

3.0

64

MB-4039-64

9

432

3.0

78

MB-4039-78

9

9

457

3.0

80

MB-4039-80

9

311

3.0

186

AV-4239-186

9

9

344

3.0

704 AV-4239-704

9

418

3.0

765 AV-4239-765

9

9

9

476

3.0

777 AV-4239-777

9

9

462

3.0

797 AV-4239-797

9

9

9

9

463

3.0

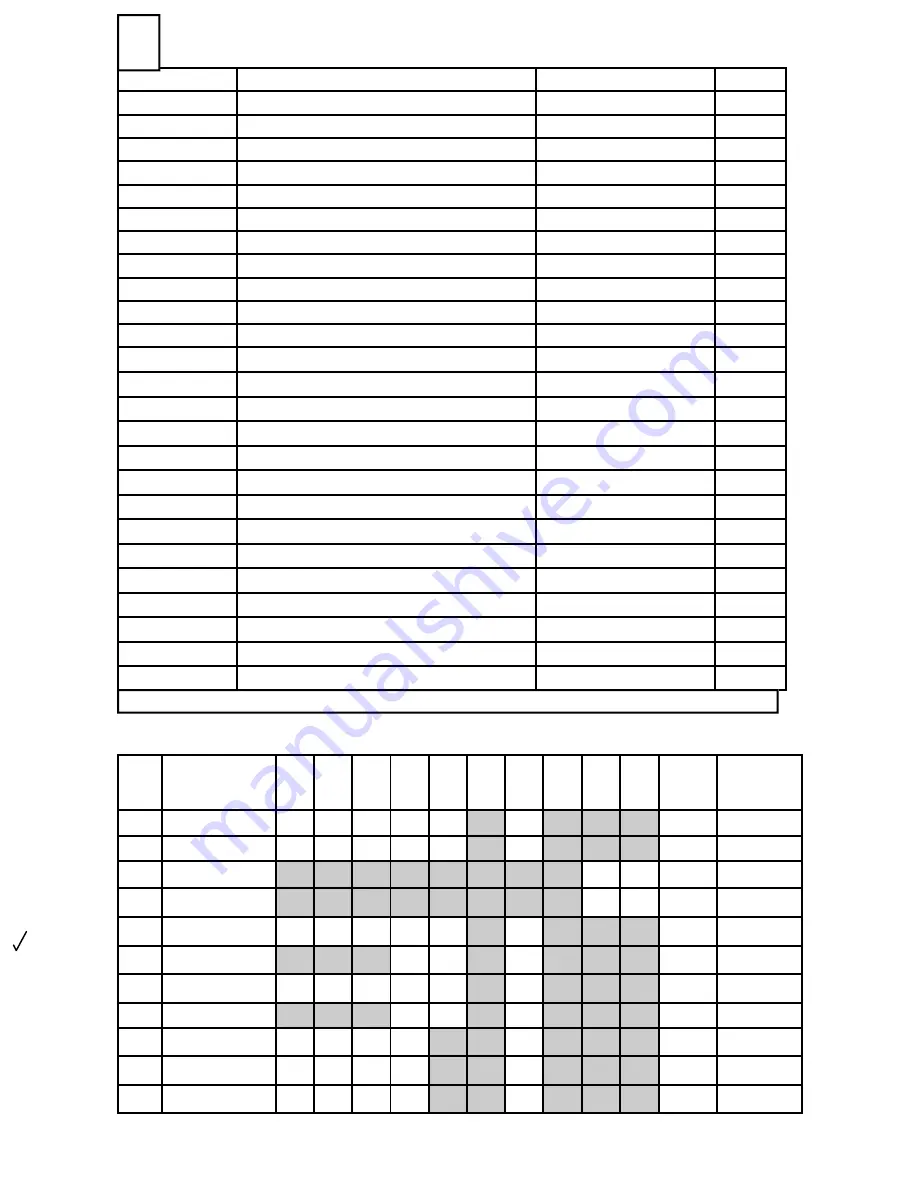

Aircap number and Nozzle size combinations

Chart 2