MAINTENANCE & TROUBLESHOOTING

PAGE 2

MAINTENANCE & TROUBLESHOOTING

PAGE 2

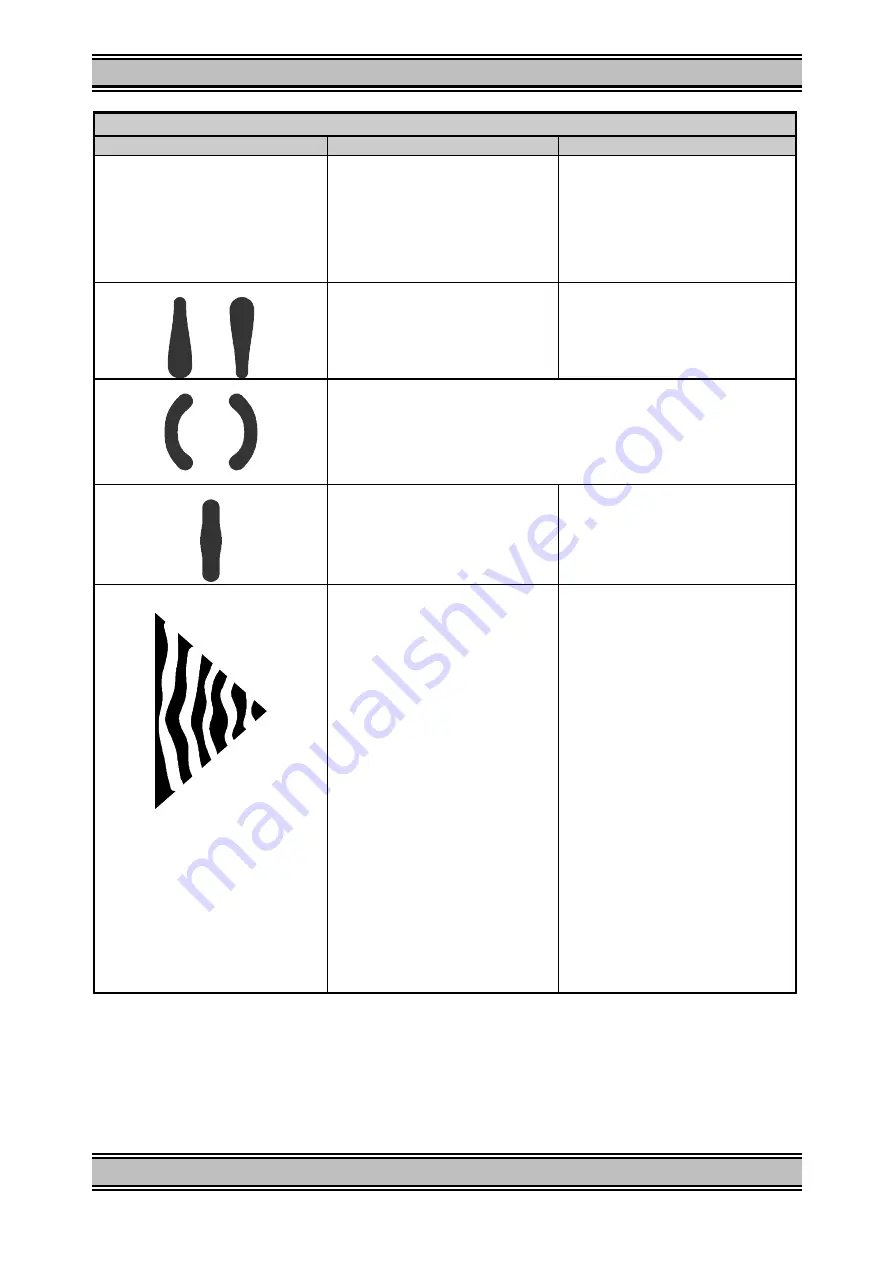

SPRAY FAULTS

Condition

Cause

Correction

Improper spray pattern

Gun Improperly adjusted.

Dirty air cap

Fluid tip obstructed

Sluggish needle

Readjust gun, follow instructions carefully.

Clean air cap.

Clean

Lubricate (see lubrication section) or

loosen packing nut.

Heavy top or bottom pattern

Material build-up on air cap, partially

plugged horn holes, centre holes or jets.

Material build-up on fluid tip or partially

plugged fluid tip

Soak cap or tip in suitable solvent and wipe

clean. To clean orifice, use a broom straw

or toothpick. Never use a wire or hard

instruments. This damages holes and

distorts spray pattern.

Heavy right or left side pattern

Note: To determine where material build-up is, invert cap and test spray. If pattern shape

stays in same position, the condition is caused by material build-up on fluid tip. If pattern

changes with cap movement, the condition is in the air cap.

Heavy centre pattern

Too much material

Material too thick

Reduce fluid flow by turning fluid needle

adjusting screw clockwise. Reduce fluid

pressure or increase atomisation pressure.

Thin

Intermittent or ‘fluttering’ spray fan

Loose fluid tip

Fluid tip not seated correctly in gun head

Gun (with cup) tipped at excessive angle.

Obstructed fluid passage or hose.

Loose or cracked fluid tube in cup or

tank.

Insufficient fluid in cup or pressure tank.

Too heavy fluid for suction feed.

Dry or worn packing or loose packing nut.

Plugged vent on suction feed cup.

Gun fluid inlet loose or not sealed/seated

correctly

Fluid hose or cup not fitted correctly to

gun fluid inlet connector

Tighten to 17 Nm (150 ibf/in)

Remove tip, clean components, check

cone seating on tip and gun for damage or

contamination

Do not tip excessively or rotate fluid tube.

Clean

Tighten or replace

Fill cup or tank

Thin material or change to pressure feed

Lubricate or replace. Tighten

Clean vent hole in cup lid.

Tighten to 8 Nm (70 lbf/in)

Remove, check mating surfaces and re-

tighten