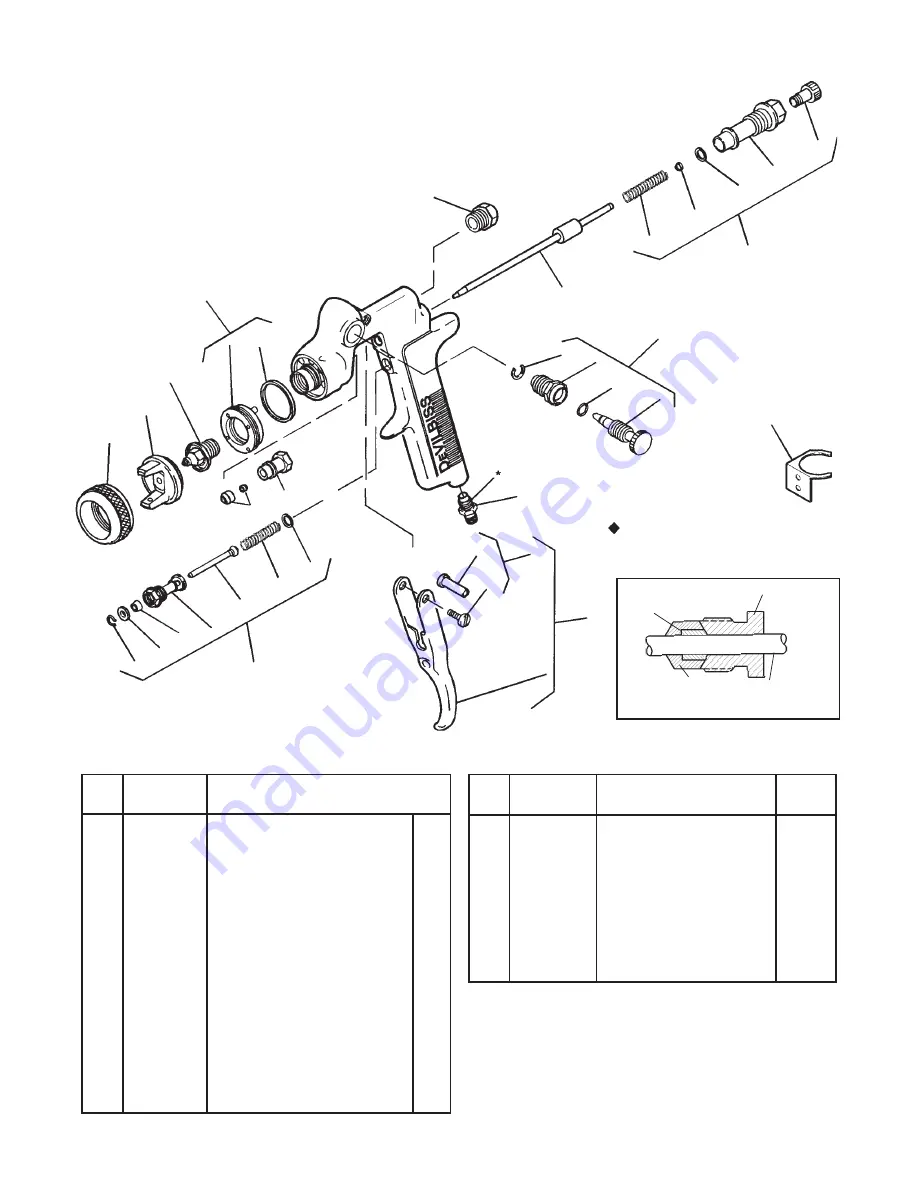

Page 4

SB-2-169-D

PARTS LIST

Ref.

Individual

No.

Part No.

Description

Parts Req.

1

MBC-368

Retaining Ring

1

2

JGHV-101-57

Air Cap

1

3

See Chart 2

Matched Fluid Tip and Needle

1

• 4

JGD-14-K10

Seal (Kit of 10) (Polyethylene)

1

5

GFHV-457-57

Baffle

1

•+ 6

JGV-463-K3

Fluid Needle Packing (Kit of 3)

1

7

34411-122-K10

Fluid Needle Packing Gland (Kit of 10)

1

• 8

——

Snap Ring

1

• 9

——

Washer

1

•+ 10

——

U-Cup

1

• 11

——

Air Valve

1

• 12

——

Spring

1

•+ 13

JGS-72-K10

Gasket (Kit of 10) (Teflon

®

)

2

14

JGS-449-1

Air Valve Assembly

1

• 15

——

Screw

1

16

——

Trigger Bearing Stud

1

17

JGS-478

Stud and Screw Kit

1

(Kit includes 3 studs and 5 screws)

18

JGS-477-1

Trigger, Stud and Screw Kit

1

(Kit includes 1 each)

•KK-5025 Gun Repair Kit includes a quantity of necessary parts and

should be kept on hand for service convenience.

+KK-5036 Soft Gun Repair Kit includes a quantity of necessary

parts.

Suffixes - K5, K10 designate kits of multiple parts. (Example) JGD-

14-K10 is a kit of 10 seals.

WARRANTY

This product is covered by

DeVilbiss' 1 Year Limited Warranty.

See SB-1-000 which is available upon request.

Ref.

Individual

No.

Part No.

Description

Parts Req.

19

P-MB-51

Air Inlet Connector 1/4" NPS(M)

1

20

GFG-413-2

Spreader Adjustment Valve

1

• 21

——

Retaining Ring

1

• +22

——

O-ring (Teflon

®

)

1

• 23

MBD-19-K10

Fluid Needle Spring (Kit of 10)

1

• 24

——

Spring Pad (Included with #23)

1

25

——

Gun Body Bushing

1

26

GTI-14

Fluid Needle Adjusting Screw

1

27

JGA-4041

Bushing, Spring & Knob Kit

1

28

6000-12

Plug

1

29

GFG-6

Gun Hook

1

Detail Ref. No. 6 - Two piece packing

covered by U.S. Patent No. 5,209,501.

+

Tapered edge faces out towards packing

nut.

+Inner Teflon Piece

Fluid Packing Nut

Fluid Needle

Outer

U.H.M.W.

Poly. Piece

* Use QH-130 (Loctite #242 med. strength

blue) sealing compound on threads.

6

7

13

1 2

11

10

16

15

14

9

8

1

2

3

(Torque to

20-25 ft. lbs.)

4

5

28

3

23

24

13

27

25

26

20

22

21

29

19 (1/4 NPS(M)

17

18