Page 6

SB-2-169-D

42884-214-K5 3/8"

42884-215-K10 5/8"

Cleaning Brushes

These brushes are helpful

in cleaning threads and re-

cesses of gun body.

HAV-500 OR

HAV-501

Adjusting Valve

(HAV-501 SHOWN)

HAV-500 does not have

pressure gauge. Use to con-

trol air usage at gun.

WR-103

Wrench

Spray Gun Lube

SSL-10 (2 oz. bottle)

GH-407 Gun

Holder

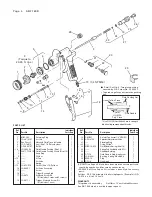

Millennium 3000

Premium Paint Spray

Respirator

HAF-507

Whirlwind™

In-Line Air Filter

Removes water, oil,

and debris from the

air line.

OMX-70-K48 Paint Cup

Liner Kit

Allows quick & easy clean-up.

Consists of:

1 - Piercing Tool

48 - Disposable Liners

48 - Drain Bushings

GH-505 Gun Holder

KK 5033-57

Air Cap Test Kit

The purpose of this

test kit is to measure

air cap atomizing air

pressure at the center

air port of the air cap.

Used to confirm code

compliance and as a

Gun holders are made

to hold standard paint

cups, gravity feed

guns and cups, and

paint filters.

Protection against organic

vapors, fumes, dusts, and mists.

(1) Wall mount bracket

included with GH-407.

Contains all necessary

tip, hose and nut sizes

used on or with gun.

Compatible with all paint

materials; contains no sili-

cone or petroleum distil-

lates to contaminate paint.

MSDS Sheet available

upon request.

GFC-501 (Acetal) 20 Oz. Cup

GFC-502 (Aluminum) 32 Oz. Cup

Gravity Feed Cups

TROUBLESHOOTING (Continued)

CONDITION

CAUSE

CORRECTION

Fluid dripping or leaking from

bottom of cup

Runs and sags

Thin, sandy coarse finish drying

before it flows out

Thick, dimpled finish "orange

peel"

Cup loose on gun.

Washer worn or missing below cup.

Cup threads dirty.

Too much material flow.

Material too thin.

Gun tilted on an angle, or gun motion too

slow.

Gun too far from surface.

Too much air pressure.

Improper thinner being used.

Gun too close to surface.

Air pressure too low.

Improper thinner being used.

Material not properly mixed.

Surface rough, oily, dirty.

Tighten.

Replace washer.

Clean.

Adjust gun or reduce fluid flow.

Mix properly or apply light coats.

Hold gun at right angle to work and adapt to

proper gun technique.

Check distance. Normally approx. 8".

Reduce air pressure and check spray pattern.

Follow paint manufacturer's mixing instrs.

Check distance. Normally approx. 8".

Too much material coarsely atomized.

Increase air pressure or reduce fluid flow.

Follow paint manufacturer's mixing instrs.

Follow paint manufacturer's mixing instrs.

Properly clean and prepare.

Joins any single piece DeVilbiss air

cap with latest version MBC-368 or

MSA-1 retaining ring. Helps prevent

parts loss and provides easier

assembly.

JGA-156-K10

Spring Clips

These gravity feed cups are designed to

be used with the GFG gravity feed spray

gun.

ACCESSORIES

Spray Gun and Cup Combinations

GFG-517 Spray Gun is sold in the following

combinations:

Each Kits includes (1) GFG-517

Spray Gun and (1) GFG-502 Cup:

GFG-618-57DFF

GFG-618-57DFW

GFG-618-57DE

Quick Disconnect Approved For

HVLP Guns (Air)

High Flow Ball and Ring Type.

HC-4700

1/4" NPT(F)

HC-1166

1/4" NPT(M)

HC-4419

1/4" NPS(F)

HC-4699

1/4" NPT(M)

Scrubs

®

are a

pre-moistened

hand cleaner

towel for paint-

ers. No water is

needed.

29-3100 Scrubs

®

Hand Cleaner Towels

WARRANTY

This product is covered by DeVilbiss' 1 Year Limited Warranty.

DeVilbiss Worldwide Sales and Service Listing: www.devilbiss.com

Industrial Finishing

DeVilbiss has authorized distributors throughout the world. For

technical assistance or the distributor nearest you, see listing below.

U.S./Canada Technical Service Office:

195 Internationale Blvd., Glendale Heights, IL 60139

Toll-Free Telephone: 1-888-992-4657 (U.S.A. and Canada only)

Toll-Free Fax: 1-800-368-8401

9/04 ©2004

Inc. All rights reserved. Printed in U.S.A.