SB-2-226-B Page 11

8.

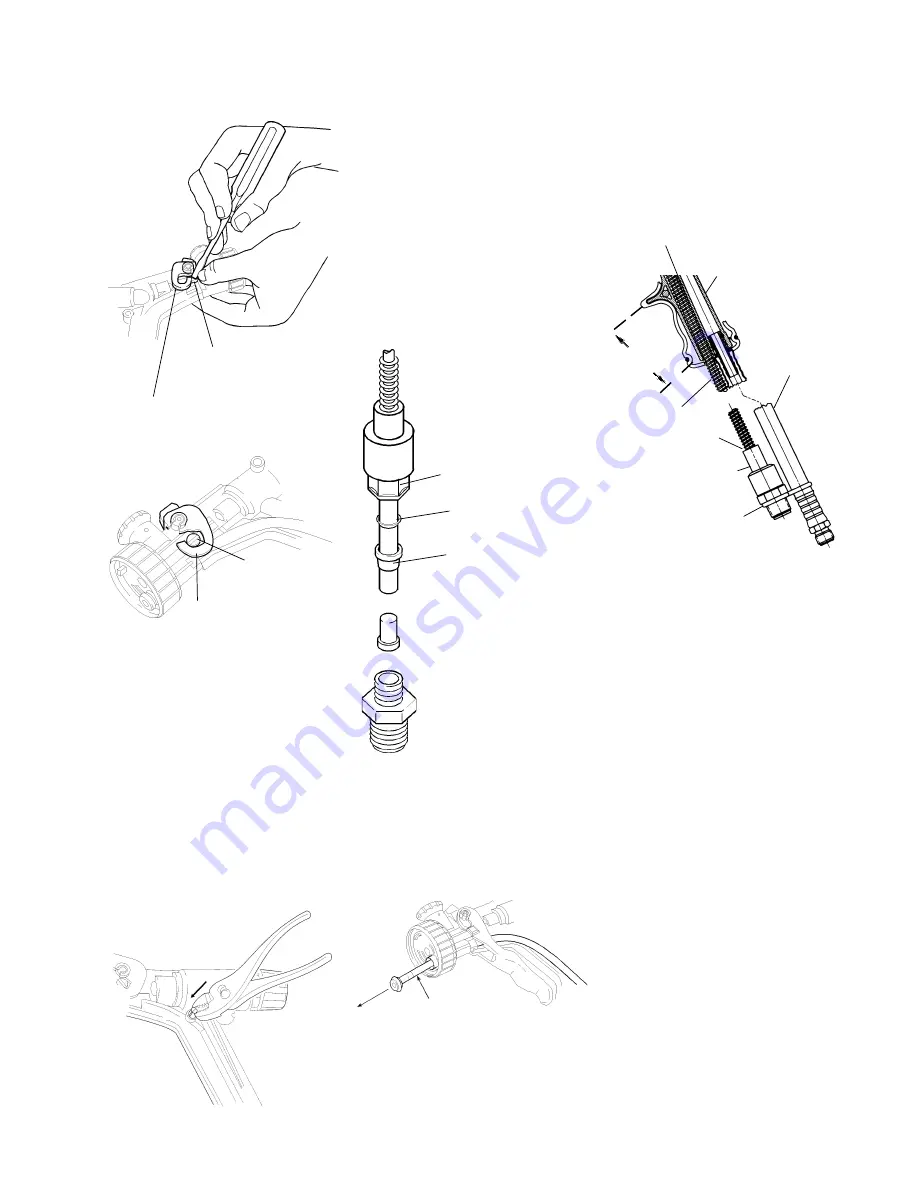

Slide kink guard spring over end of

fluid tube. Spring should extend

approximately 3" into skeleton as

shown in illustration. Press spring

(requires a little force) into slot at

base of skeleton.

Figure 21

9. Install left and right grips onto gun

using grip clips.

1 0 . Compress spring guard on opposite

end to expose nylon tube.

11. Slide spring retainer over tube

against spring.

12. Assemble fluid connector to tube.

13. Push spring retainer tightly over

fluid connector.

14. Push spring into opening of spring

retainer with a twisting action.

Insert a minimum of 1/2".

15. Install “S” clip to air hose and fluid

connector.

1 6 . Install spray head.

Air Fitting (42)

1.

Refer to gun grips procedure and

remove gun grips (38 and 39).

2.

Pull lower spring clip (44) from gun

body handle, and pull air fitting (42)

from gun handle.

3 .

Install end of air fitting (42) into gun

body handle.

4 .

Push on air fitting until you can see

daylight through lower spring clip

hole and install lower spring clip (44)

into gun body.

5.

Refer to gun grips procedure and

install gun grips (38 and 39).

Figure 16

Figure 17

Pneumatic Trigger Module (52)

1.

Refer to gun grip procedure and

remove gun grips (37) and (38).

2.

To remove pneumatic trigger mod-

ule (52), squeeze the retaining barbs

with a pair of pliers and push to-

wards the skeleton (Figure 18). Pull

valve out of skeleton from the

opposite side.

3.

Install new pneumatic valve (52) by

locating valve body into skeleton,

then pushing until retaining barbs

engage on opposite side of skeleton.

Lube O-ring with SSL-10 gun lube

prior to assembly.

4.

Refer to gun grip procedure and in-

stall gun grips (37) and (38).

Figure 18

Fluid Tube and Spring Guard Assembly

1 .

Refer to gun grips procedure and re-

move gun grips (38 and 39).

2 .

Refer to fluid head and needle assem-

bly procedure and remove head and

needle.

3 .

Remove packing/spring (7).

4 .

Remove spring retainer and tube con-

nector (48) from fluid tube. Remove

connector nut, ferrule, ferrule

washer, and P-tube, Figure 19,

from fluid tube.

5.

Pull fluid tube through loops of

spring.

Figure 19

6 .

Pull fluid tube out from front of gun

body, Figure 20.

7 .

Install fluid tube assembly (47) into

round hole at bottom of gun

skeleton.

Figure 20

T-Block

Actuator

Arm

T-Block

Actuator

Arm

Ferrule Washer

Ferrule

P-Tube

Connector Nut

Connector

Note:

Be sure to screw connector

nut completely onto connector un-

til it bottoms out. Also, be sure

tube is bottomed out into

connector.

Fluid Tube

Press spring

into skeleton.

Skeleton

Approx. 3"

Spring Guard

Push spring

tightly

into retainer

Spring Retainer

Fluid

Connector

Air Hose

(Ref.)