Page 6 SB-2-226-B

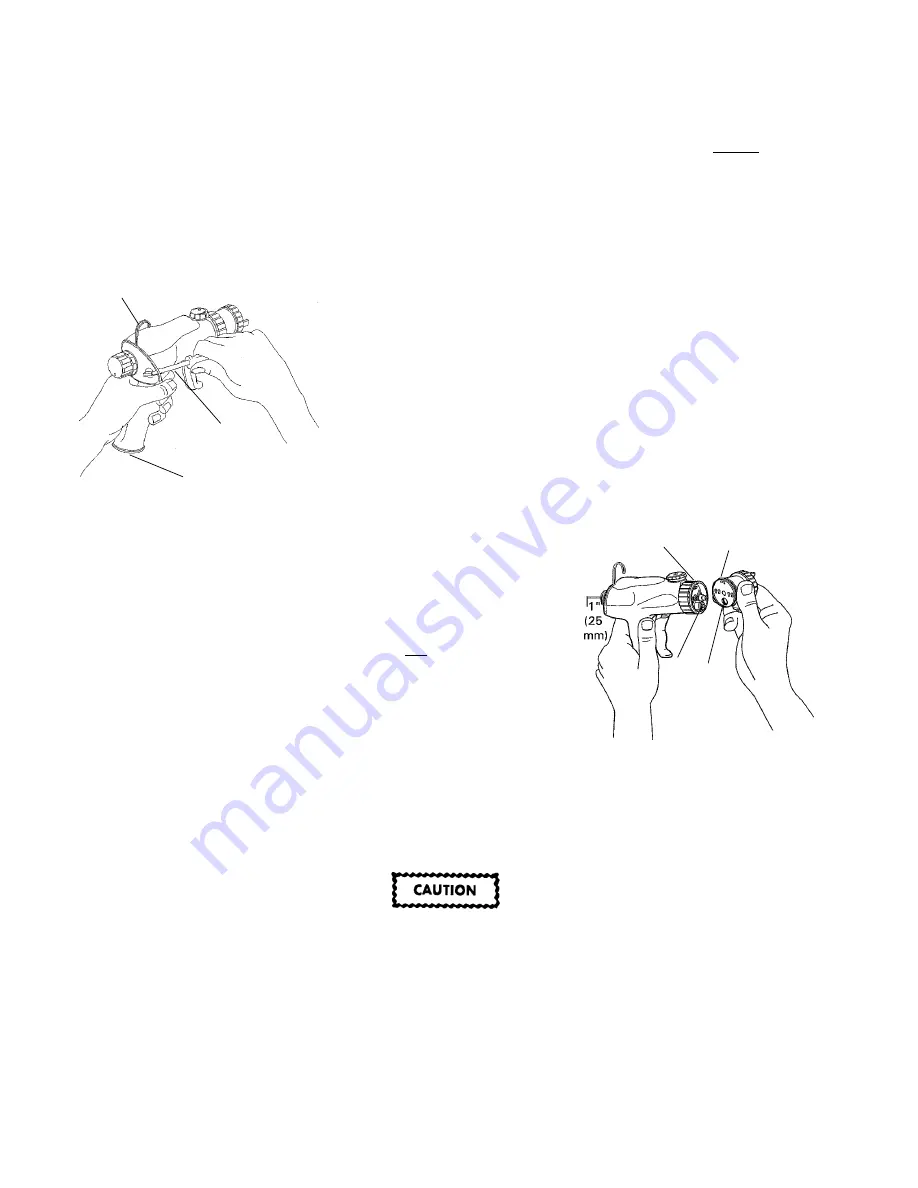

Gun Grips (38 and 39)

1 .

Place 1/4" (6 mm) flat blade screw-

driver, Figure 7, and pry upper clip

out of groove. Expand the bottom

of the clip to remove from the

mounting slots.

2.

To remove the lower clip (41) from

the gun grips, use a pair of external

retaining pliers or push down on the

clip tabs with your thumbs.

3 .

Separate grips at handle and top by

prying christmas tree clips (37).

4.

Pull outward on the back of each

grip to disengage the grips from the

notch at the front of the body under

the fluid head retaining ring (15).

5.

To reassembly grips, install right gun

grip. Push grip down into position.

6 .

Install tab on left gun grip (38) into

slot under retaining ring and push

grip down into position.

7.

Push grips together at christmas

tree clips (37).

8.

Install lower clip (41) and upper clip

(40).

Air Valve Bushing (29), Seal (28), Piston

(30), and Air Seal (33) (Parts included in

Gun Repair Kit KK-5054)

Note

It is recommended that you use

the gun repair kit KK-5054, Fig-

ure 9, when undertaking this pro-

cedure. Use all parts provided in

the kit. Refer to the various pro-

cedures in this manual to access

all kit parts.

1 .

Refer to gun grips procedure and

remove gun grips (38 and 39, Figure

10).

2.

Refer to fluid head and needle

assembly procedure and remove

head and needle assembly.

3.

Remove packing/spring (7), fluid

tube o-ring (10), and baffle seal (11).

16. Install baffle seal (11) into face of

spray gun body.

17. Install o-ring (10) onto fluid tube (47).

Lubricate o-ring with SSL-10 gun lube.

1 8 . Install needle (12) partially into gun

body through rear opening, Figure 8.

Leave about 1" of needle exposed

out rear of gun.

19. Apply two drops of gun lube to fluid

head (6) threads. (Lubrication facili-

tates removal of parts after use.)

20. Place packing/spring (7) on the end

of the needle.

21. Place fluid head against gun body,

ensuring fluid head lines up with fluid

tube opening, Figure 8. Firmly push

fluid head over fluid tube o-ring

and against head retaining ring.

22. Turn head retaining ring (15) coun-

terclockwise to draw fluid head

onto body. Hand tighten head retain-

ing ring until fluid head is drawn

firmly against the gun body.

23. Push needle in completely. Install

needle spring (13) and screw in fluid

control knob (35). Turn knob com-

pletely in clockwise, then back out

1-1/2 to 2 turns for full fluid flow.

Figure 8

25. Apply SSL-10 gun lube to the air cap

threads. Screw the air cap assembly

(1) onto the fluid head (6). Tighten

hand tight, do not overtighten.

26. Refer to gun grip procedure and

install gun grips (38 and 39).

4.

Using a 1-1/16 inch (27 mm) socket

or adjustable wrench, unscrew rear

plug (34) from gun body.

5.

Remove piston return spring (31).

Using your finger, push air seal (33)

out of rear plug (34).

6.

Remove piston assembly (30). You

can either remove the piston by

striking the back of the gun body

against the palm of your hand or by

pulling it out with a pair of needle

nose pliers.

7 .

Remove air valve bushing (29) and

seal (28). To remove, use a dental

pick to catch the center hole, and

pull out.

8.

(OPTIONAL) Pull out air inlet retainer

(24) and remove air inlet plug (25)

with o-ring (26).

9 .

Pull out lower spring clip (44) and

remove air fitting (42). Remove

o-rings (43) from fitting.

Note

When assembling spray gun,

lube all sliding parts with pure

petroleum jelly (petroleum based

grease).

10. Install o-rings (43) into fitting (42), the

lower groove is for lower spring clip.

Lubricate o-rings (43) and slide fitting

into skeleton.

1 1 . Push on fitting until you can see light

through the lower spring clip hole

and install lower spring clip (44) into

skeleton. Install spring clip into gun

body form the left hand side.

12. Apply a thin film of pure petroleum

jelly (petroleum based grease) to in-

side diameter of the skeleton (50) and

outer surface of piston shaft (30).

Install piston assembly (30) into air

valve bushing (29). Slide u-cup seal

(28), grooved end towards bushing,

onto piston shaft.

1 3 . Install assembled air valve bushing

and piston into gun body. Push in

completely.

1 4 . Install air seal (33, Figure 8), tapered

end first, into rear plug (34). Install

spring (31) into plug.

Overtightening can damage the

plug or gun skeleton. When

tightening rear plug into gun

body do not overtighten. Snug

only.

15. Push assembled rear plug into back

of gun body and thread into gun. Use

a 1-1/6 inch (27 mm) socket or cres-

cent wrench to snug rear plug into

gun body, do not overtighten.

Figure 7

Flat Blade

Screwdriver

Upper Clip

Lower Clip

Fluid Head

Head Retaining

Ring

Fluid

Tube

Fluid

Tube

Opening