8

ASSEMBLY INSTRUCTIONS

Installing Handle, Foot Extension

Bracket, Wheels, Outlet Valve

THE WHEELS AND HANDLE DO NOT PRO-

VIDE ADEQUATE CLEARANCE, STABILITY

OR SUPPORT FOR PULLING THE UNIT UP

AND DOWN STAIRS OR STEPS. THE UNIT

MUST BE LIFTED OR PUSHED UP A RAMP.

Do not use the engine gas tank as a support

for lifting the air compressor.

1.

Insert the handle into pockets under the tank

saddle. Put one set screw through hole in one side

of tank saddle and tighten down on handle.

It may be necessary to brace or support one

end of the outfit when attaching the wheels

and the foot extension bracket because the

air compressor will have a tendency to tip

before both wheels are assembled.

Items Needed for Assembly

•

20 oz. of oil for the engine (see Briggs & Stratton

instructions). Use 10W30 high quality motor oil.

•

16 oz. of compressor oil, SAE 20-20W, non-deter-

gent, low foaming.

•

a 9/16" socket or open-end wrench for attaching the

wheels.

•

a 7/16" open-end wrench for attaching the foot

extension bracket and rubber feet.

•

a 1/4" open-end wrench to tighten handle set

screw.

•

an adjustable wrench for attaching the shut-off

valve and air outlet adapter.

EXCESSIVE TANK VIBRATION CAN WEAK-

EN THE AIR TANK AND CAUSE RUPTURE

OR EXPLOSION. RUBBER FEET MUST BE

INSTALLED.

2.

Attach the rubber feet to the bottom of the foot

extension bracket. Attach foot extension bracket to

the air tank bracket. Use one cap screw, one lock

washer, and one hex nut at each end. Tighten.

3.

The leg bracket on the underside of the air com-

pressor tank has 2 holes on each side for mounting

the wheels. Place one shoulder bolt through the

hole in a wheel. Next, push the bolt through the

LOWER

hole of the leg bracket and screw on one

hex locking nut. The special locking nut does not

turn freely. Tighten the nut firmly until it contacts the

tank leg. See separate Parts Manual. The outfit will

sit level if the wheels are properly installed.

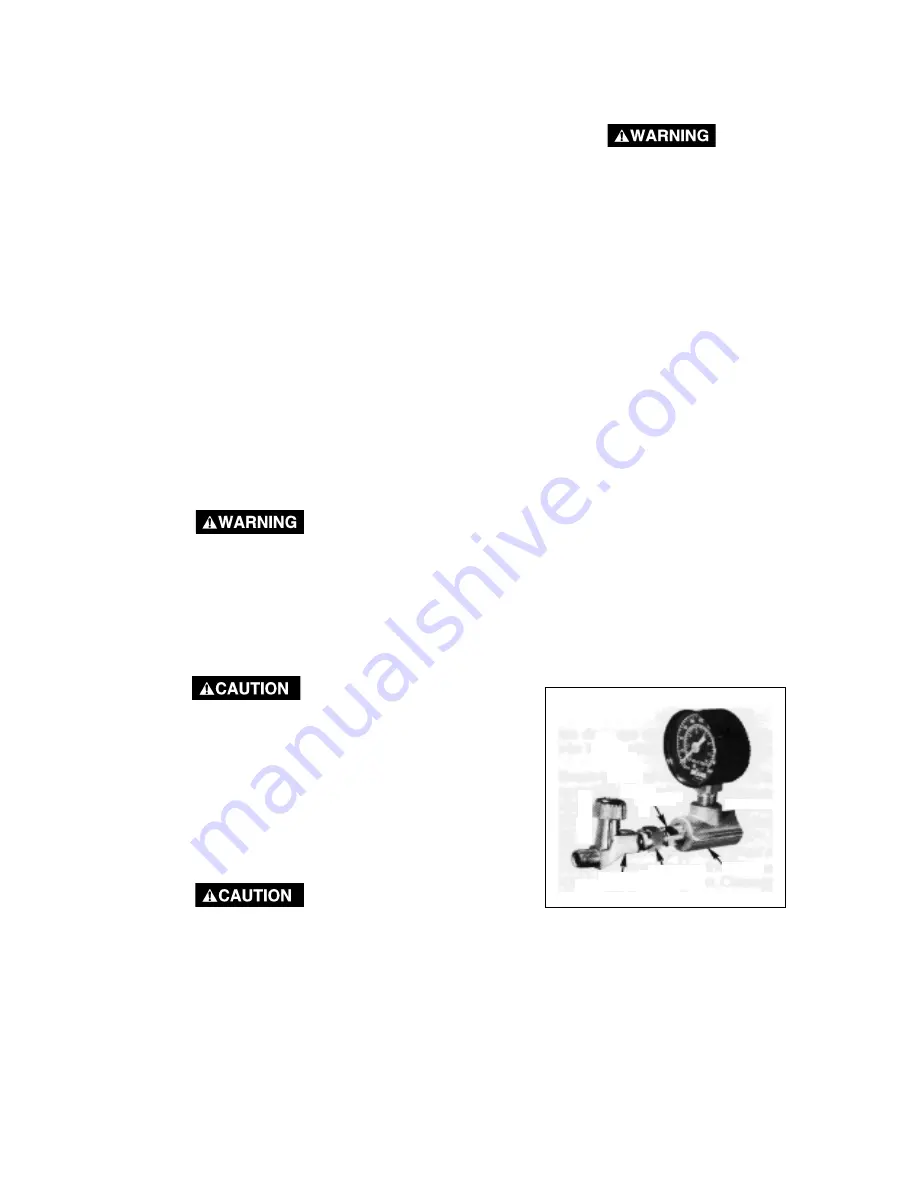

4.

Apply teflon tape to the tapered pipe threads on the

adapter and tighten into the manifold. Install the

swivel connection end of the shut-off valve to the

straight threaded end of the adapter (teflon tape is

not required) and tighten this connection. See photo

below.

5.

Attach the spark plug wire to the spark plug.

ADAPTER

SHUT-OFF

VALVE

MANIFOLD

SWIVEL

CONNECTION

Summary of Contents for MG4-OLENG-2B

Page 18: ...18 SERVICE NOTES...

Page 19: ...19 SERVICE NOTES...