Page 2 SB-2-319-C

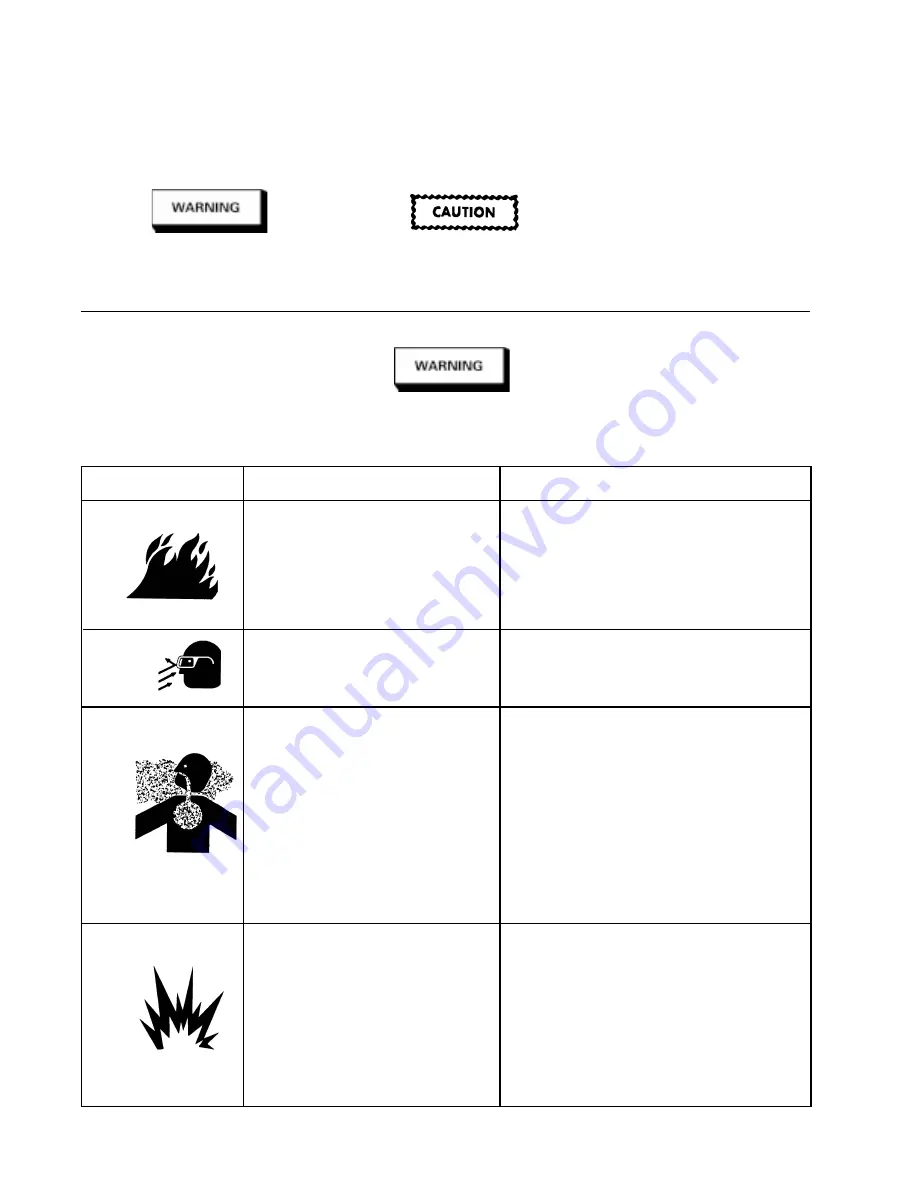

HAZARD

CAUSE

SAFEGUARDS

Fire

Solvent and coatings can be highly

Adequate exhaust must be provided to keep

flammable or combustible, especially

air free of accumulations of flammable vapors.

when sprayed.

Smoking must never be allowed in the spray area.

Fire extinguishing equipment must be present

in the spray area.

Solvent Spray

During cleaning and flushing, sol-

Wear eye protection.

vents can be forcefully expelled

from fluid and air passages. Some

solvents can cause eye injury.

Inhaling Toxic Substances

Certain materials may be harmful

Follow the requirements of the Material Safety

if inhaled, or if there is contact

Data Sheet supplied by your coating material

with the skin.

manufacturer.

Adequate exhaust must be provided to keep the

air free of accumulations of toxic materials.

Use a mask or respirator whenever there is a

chance of inhaling sprayed materials. The mask

must be compatible with the material being

sprayed and its concentration. Equipment must

be as prescribed by an industrial hygienst or safety

expert, and be NIOSH approved.

Explosion Hazard -

Halogenated hydrocarbon solvents

This gun can be used with these solvents.

- for example; methylene chloride

However, aluminum is widely used in other spray

and 1, 1, 1 - Trichloroethane can

application equipment - such as, material pumps,

chemically react with aluminum.

cups, regulators, valves, etc. Check all other equip-

The chemical reaction caused by

ment items before use and make sure they can

these solvents reacting with aluminum

also be used safely with these solvents. Read the

can become violent and lead to an

label or material data sheet for the material you

equipment explosion.

intend to spray. If in doubt as to whether or not a

coating or cleaning material is compatible, contact

your material supplier.

SAFETY PRECAUTIONS

This manual contains information that is improtant for you to know and understand. This information relates to USER SAFETY and

PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the following symbols. Please pay particular

attention to these sections.

Important information that tells how to

prevent damage to equipment, or how

to avoid a situation that may cause

minor inury.

Note

Information that you should pay spe-

cial attention to.

Important safety information - A hazard

that may cause serious injury or loss of

life.

The following hazards may occur during the normal use of this equipment.

Please read the following chart before using this equipment.