SB-2-293-C Page 3

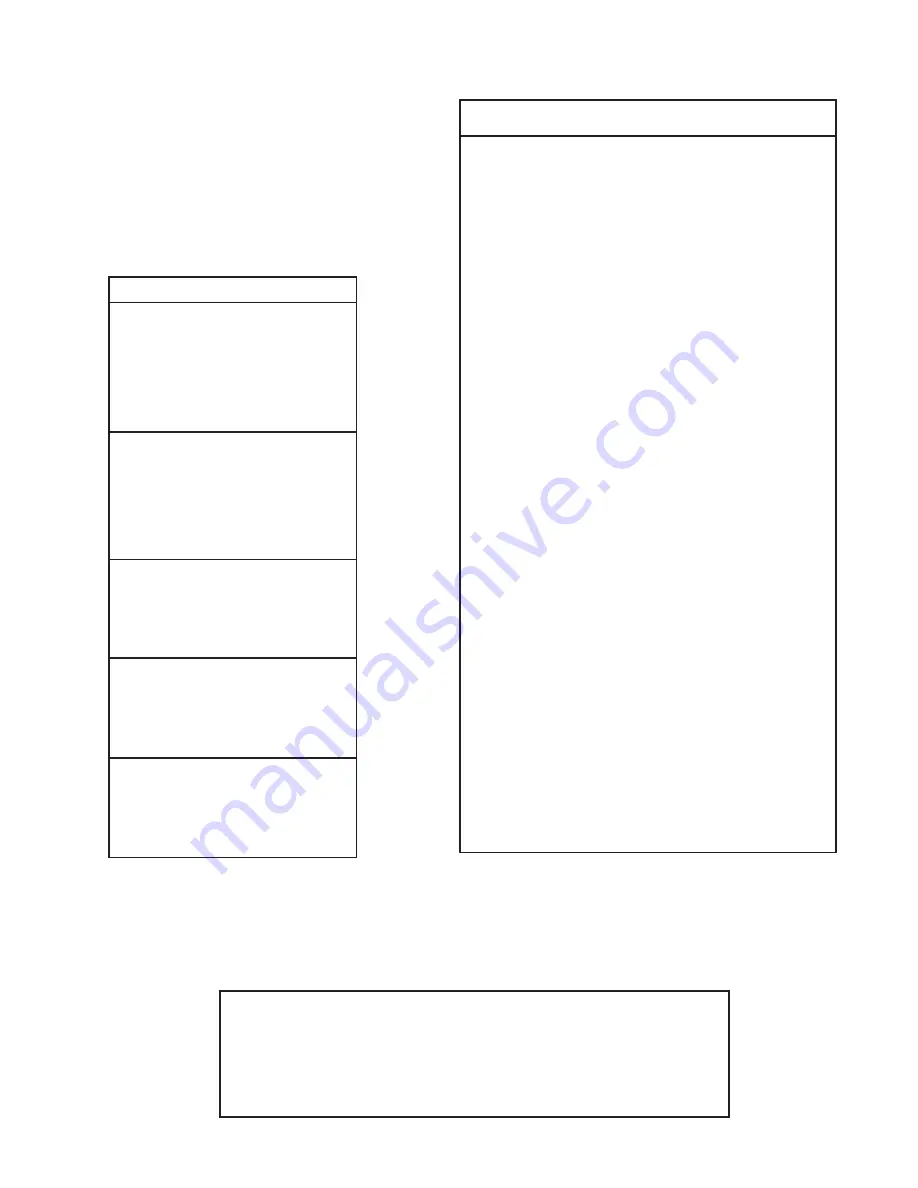

PARTS LIST

Ref.

Replacement

Individual

No.

Part No.

Description

Parts Req

1

54-4160

Retaining Ring

1

2

54-4980

Air Cap

1

3

45-10000

Nozzle Assembly

1

•4

▲

GTI-33-K5

Seal Kit (Kit of 5)

1

5

GTI-425

Baffle Assembly

1

6

MSV-3-K10

Gasket (blue)

1

7

----

Locknut

1

8

----

Fluid Inlet Adapter

1

3/8" NPS(M)

9

JGA-4044

Fluid Inlet and Nut Kit

1

•10

▲

JGV-463-K3

Needle Packing Assembly

1

(Kit of 3)

11

34411-122-K10

Fluid Needle Packing Nut

1

(Kit of 10)

•12

JGA-14-K25

Snap Ring (Kit of 25)

1

•13

JGA-15-K25

Washer (Kit of 25)

1

•14

▲

JGS-26-K25

U-Cup (Kit of 25)

1

•15

JGS-431-K25

Air Valve Assembly (Kit of 25) 1

•16

MBD-12-K25

Spring (Kit of 25)

1

•17

▲

JGS-72-K10

Gasket (Kit of 10) (Teflon)

2

18

JGS-449-1

Air Valve Assembly

1

•19

----

Screw

1

20

----

Trigger Bearing Stud

1

21

JGS-478

Stud and Screw Kit

1

(Kit includes 3 studs

and 5 screws)

22

JGS-477-1

Trigger, Stud & Screw Kit

1

(Kit includes 1 each)

23

JGA-132

Plug

1

24

MSA-3

Connector 1/4" NPS

1

25

54-4162

Air Valve Plug

1

26

JGA-402-E

Fluid Needle

1

27

-----

Gun Body Bushing

1

•28

MBD-19-K10

6# Spring (Kit of 10)

1

MSA-4-K10

4# Spring (Kit of 10)

1

(Optional)

•29

-----

Spring Pad (included

1

with #28 and 31)

30

JGS-16

Fluid Needle Adjusting Screw 1

31

JGA-4041

Bushing, Spring, Knob Kit

1

32

See Chart 1

Spray Tip Assembly

1

•

A quantity of necessary parts is included in

Repair Kit KK-5064. This kit should be kept

on hand for service convenience.

▲

A quantity of necessary parts is included in

Soft Seal Kit KK-5065.

Suffixes -K3, -K5, -K10, etc. designate kits of multiple parts.

(Example) GTI-33-K5 is a kit of 5 seals.

FLUID TIP SELECTION

Factors to consider in selecting a fluid tip for an air-

assisted airless spray gun include: (1) the size of the parts

being sprayed; (2) the production line speed; (3) the

material flow rate and film thickness; (4) the viscosity of

the material applied; (5) the type of material applied; and

(6) the quality of atomization of the coating required. The

selection of a fluid tip necessary to perform a specific

spraying job is best determined through a combination

of experimentation and expert advice from your material

equipment suppliers.

CHART 1

SPRAY TIP SELECTION

PART NO.

SIZE

FAN WIDTH

113-01706

.017

4"-6"

113-01708

.017

6"-8"

113-01710

.017

8"-10"

113-01712

.017

10"-12"

113-01714

.017

12"-14"

113-01716

.017

14"-16"

113-01718

.017

16"-18"

PART NO.

SIZE

FAN WIDTH

113-01906

.019

4"-6"

113-01908

.019

6"-8"

113-01910

.019

8"-10"

113-01912

.019

10"-12"

113-01914

.019

12"-14"

113-01916

.019

14"-16"

113-01918

.019

16"-18"

PART NO.

SIZE

FAN WIDTH

113-02110

.021

8"-10"

113-02112

.021

10"-12"

113-02114

.021

12"-14"

113-02116

.021

14"-16"

113-02118

.021

16"-18"

PART NO.

SIZE

FAN WIDTH

113-02410

.024

8"-10"

113-02412

.024

10"-12"

113-02414

.024

12"-14"

113-02416

.024

14"-16"

113-02418

.024

16"-18"

PART NO.

SIZE

FAN WIDTH

113-02710

.027

8"-10"

113-02712

.027

10"-12"

113-02714

.027

12"-14"

113-02716

.027

14"-16"

113-02718

.027

16"-18"

With an inlet air pressure of 20 p.s.i., the compliant air cap registers 10 p.s.i. of

atomization air. The MSHTE H.V.L.P. gun operates at high transfer efficiencies

and fully complies with all government regulations for H.V.L.P. spray guns.

Maximum dynamic gun inlet pressure:

20 p.s.i.

Important Regulatory Note

PTFE