Page 6 SB-2-293-C

ACCESSORIES

TROUBLESHOOTING (continued)

CONDITION

CAUSE

CORRECTION

Thin, sandy coarse finish

Gun too far from surface.

Check distance. Normally approx. 8".

drying before it flows out

Too much air pressure.

Reduce air pressure and check spray pattern.

Improper thinner being used.

Follow paint manufacturer's mixing instructions.

Thick, dimpled finish "orange

Gun too close to surface.

Check distance. Normally approx. 8".

peel".

Too much material coarsely atomized.

Increase air pressure or decrease fluid pressure.

Air pressure too low.

Increase air pressure or reduce fluid pressure.

Improper thinner being used.

Follow paint manufacturer's mixing instructions.

Material not properly mixed.

Follow paint manufacturer's mixing instructions.

Surface rough, oily, dirty.

Properly clean and prepare.

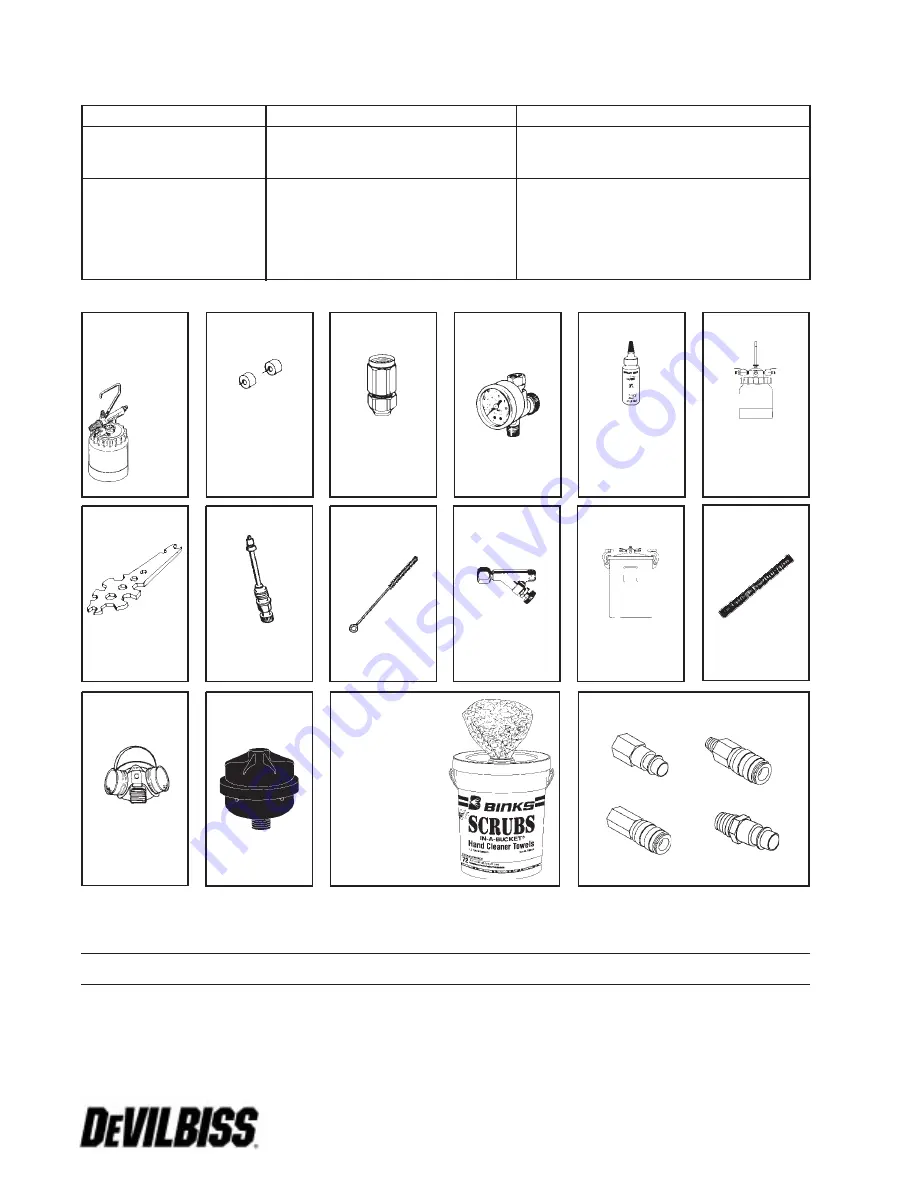

KB-555 Alum. &

KB-545-SS

Stainless Steel

2 Qt.

Pressure Feed Cups

Includes

a 0-30 psi

gauge.

JGA-52-K10

Leather Packings

Used when abrasive

materials are

sprayed (i.e. porce-

lain enamel). Use

(2) JGA-52 packings

in place of JGV-463

packing.

HAV-500 or

HAV-501

Adjusting Valve

(HAV-501 Shown)

Use to control air

pressure at gun.

(HAV-500 has no

gauge.)

Compatible with all

paint materials:

contains no silicone

or petroleum distil-

lates to contaminate

paint. MSDS avail-

able upon request.

Spray Gun Lube

SSL-10 (2 oz. bottle)

2 Quart Hose

Cleaner used to

clean the inside of

hose and material

passages of gun. 2

Gallon galvanized

also available.

HD-503

SolventSaver™

VS-531

Low Pressure

Strainers

The VS-531 Low

Pressure Fluid

S t r a i n e r

provides a final fil-

ter for trapping for-

eign particles in the

paint supply.

Enables user to con-

trol and reduce air

usage at the gun.

Ideal for low pres-

sure spraying.

P-H-5516 Air

Adjusting Valve

42884-214-K5 (3/8")

&

42884-215-K10 (5/8")

Cleaning Brushes

These brushes are

helpful in cleaning

threads and re-

cesses of gun body.

GTI-415

Air Adjusting Valve

Allows air adjust-

ment at the gun.

Replaces JGA-132

plug.

Contains all neces-

sary tip, hose and

nut sizes used on or

with gun.

WR-103 Wrench

QMGZ

SolventSaver™

Hose/Gun Cleaner

2 Gallon galvanized

tank used to clean

the inside of hose

and material pas-

sages of the gun.

Provides reduced

spring force (4 lbs.

versus 6 lbs.) for

easier trigger pull.

MSA-4-K10 Fluid

Needle Spring

(replaces MBD-19)

NIOSH-Certified

(TC-84A-1623) for

respiratory protec-

tion in atmospheres

not immediately

dangerous to life.

Millennium 3000

Twin Cartridge,

Paint Spray

Respirator

HAF-507

Whirlwind™

In-Line Air Filter

Removes water,

oil, and debris

from the air line.

HC-4419

1/4" NPS(F)

HC-4699 1/4" NPT(M)

HC-4700

1/4" NPT(F)

HC-1166

1/4" NPT(M)

Quick Disconnect Approved for

HVLP Guns (Air)

High Flow Ball and Ring Type

6/04 ©2004

Inc. All rights reserved. Printed in U.S.A.

WARRANTY

This product is covered by DeVilbiss' 1 Year Limited Warranty.

DeVilbiss Worldwide Sales and Service Listing: www.devilbiss.com

Industrial Finishing

DeVilbiss has authorized distributors throughout the world. For

technical assistance or the distributor nearest you, see listing below.

U.S./Canada Technical Service Office:

195 Internationale Blvd., Glendale Heights, IL 60139

Toll-Free Telephone: 1-888-992-4657 (U.S.A. and Canada only)

Toll-Free Fax: 1-800-368-8401

Scrubs® are a pre-

moistened hand

cleaner towel for

painters. No water is

needed.

29-3100 Scrubs

®

Hand Cleaner Towels