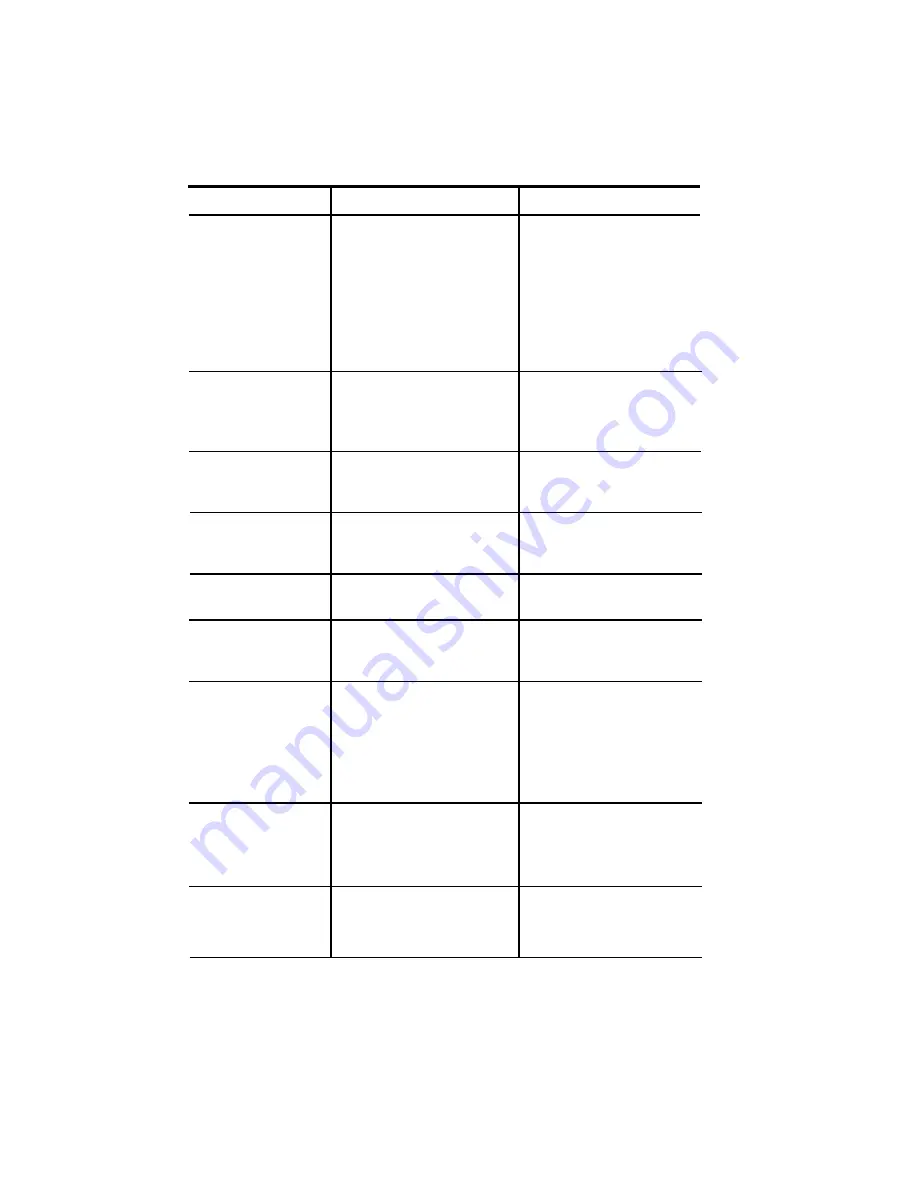

PAGE

16

SOLUTION

Replace feed pawl. Contact an

*AWSC

Replace feed pawl spring.

Fasteners recommended for tool

must be used.

Replace with undamaged

fasteners.

Set platform to correct height.

Adjust air pressure to the correct

PSI for that particular model

nailer/stapler.

Repair trigger action.

Purchase a

Trigger Repair Kit

Tighten screws.

Install head valve piston set.

Contact an

*AWSC

Install head valve piston set.

Contact an

*AWSC

Tighten screws.

Replace bumper or piston

assembly. Purchase a

Bottom

Repair Kit

Check PSI and CFM.

Install head valve piston set.

Contact an

*AWSC

Disassemble and clean cylinder.

Replace bumper.

Purchase

Bottom Repair Kit

Replace piston assembly. On the

NBSNC2x4 contact an

*AWSC

for correct part. All other nailers

purchase

Bottom Repair Kit

.

Check PSI and CFM.

Replace piston assembly. On the

NBSNC2x4 contact

*AWSC

for

correct part. All other nailers

purchase

Bottom Repair Kit

.

Tilting the tool to the left 10° will

eliminate the indention.

PROBLEM

Fasteners are jammed in

tool.

Nailer/Stapler misfires or

sinks two nails/staples at

the same time.

Air leak near top of tool.

Sluggish operation.

Air leak near bottom of

tool.

Tool does nothing.

Poor driver blade return.

Weak Drive.

NBSNC2X4 leaving a

1/4” indention.

CAUSE

Worn/damaged feed pawl.

Worn/damaged feed pawl spring.

Fasteners are not correct size.

Fasteners are bent.

Nail height setting incorrect.

Air pressure regulated too high.

Trigger action faulty.

Loose exhaust cover screws.

O-rings failed on head valve.

O-rings blown on head valve.

Loose driver guide screws.

Bumper or piston o-rings worn.

Air supply inadequate.

O-rings failed on head valve

piston set.

Dirty cylinder.

Worn Bumper.

O-rings worn in piston assembly.

Inadequate air supply.

Worn piston assembly.

Driver blade width is 1/4” making

it possible to use staples and

brad nails in the same tool

TROUBLESHOOTING GUIDE (cont'd)

*AWSC – Authorized Warranty Service Center: see back page for details