Manual_Revised_V1.0

Page 14

APPLICATION

WARNING:

To reduce the risk of

explosion, before any work check the utility

lines electricity , gas or water supply line

are hidden in the work area.

WARNING:

When working at low

temperatures:

The hammering mechanism begins to operate

only when the tool has reached a minimum

operating temperature.

Press the tip of the hammer bit briefly against

the work surface while the tool is running.

Repeat this procedure if necessary until the

hammering reaches the minimum operating

temperature.

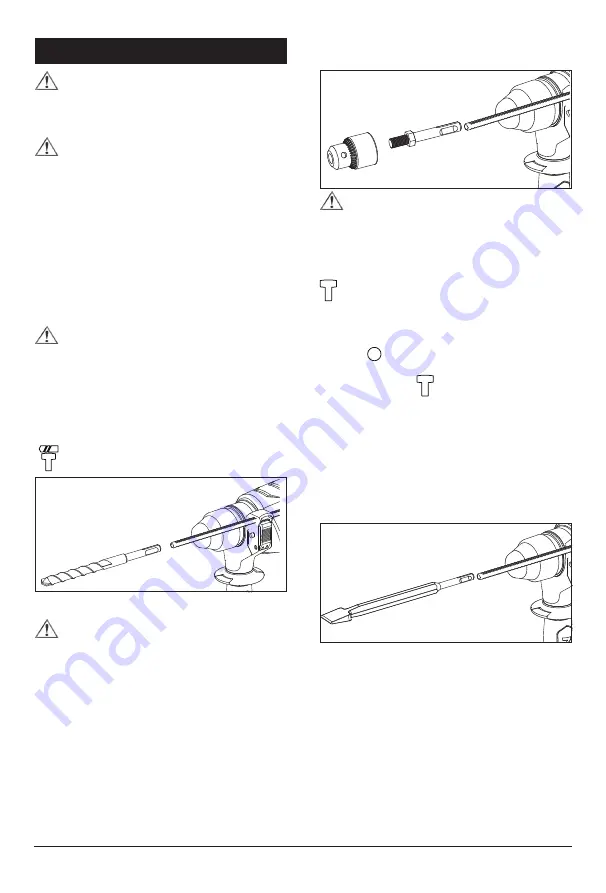

1. Hammer drilling

WARNING:

Do not use tools without SDS-

plus for hammer drilling!

Tools without SDS-plus and their holder and

drill chuck would be damaged by hammer

drilling.

When working with tool without SDS-plus, set

the operating mode selector knob to position

“

”.

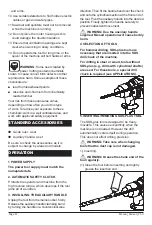

2. Drilling

WARNING:

To work with tools without

SDS-plus (e.g., drill with cylindrical shafts),

a suitable drill chuck must be used.

Screw the SDS-plus adapter shaft (accessory)

into a ring-gear or quick clamping drill chuck.

Clean the adapter shaft and lightly grease the

insertion end before inserting.

Insert the shaft of the assembled drill chuck

with a twisting motion into the tool holder until it

can be heard to lock.

The adapter shaft locks itself. Check the

locking by pulling on drill chuck.

To remove the drill chuck, pull the plastic

sleever to the rear, hold in this position and

remove the drill chuck from the tool holder.

WARNING:

Never use standard chucks

in the Drilling mode.

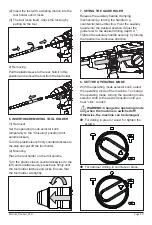

3. Chipping and chiseling

Before inserting the chisel, set the operating

mode selector knob to the “hammering only”

position.

Insert the appropriate chisel. To adjust the

head of the chisel to the desired angle, set

the operating mode selector knob to the “bit

rotation” position and rotate the chisel

by hand. Return the mode selector to the

“hammering only”

position.

Adjust the auxiliary handle as required.

Start on the trigger of tool and start working.

Hold the tool firmly with both hands, Turn

the tool on and apply slight pressure on the

tool so that the tool will not bounce around,

uncontrolled. Pressing very hard on the tool will

not increase the efficiency.

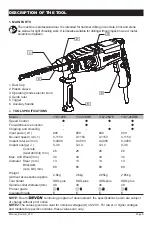

Summary of Contents for 1107-26DE

Page 1: ...PROFESSIONAL TOOLS GB Rotary Hammer 1107 26E 1107 26RE 1107 26DE 1107 26DRE...

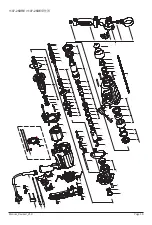

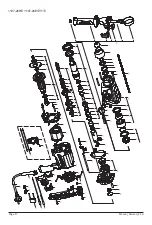

Page 3: ...Manual_Revised_V1 0 Page 2 1 1 2 3 2 1 2 3 4 5 6 RCD RCD 3 1 2 3 4 5 6 7 4 1 2 3 4 5 6 7 5...

Page 5: ...Manual_Revised_V1 0 Page 4 5 SDS plus SDS plus 1 1 2 3 2 6 1 2 7 SDS plus 8...

Page 6: ...Page 5 Manual_Revised_V1 0 9 10 1 2...

Page 7: ...Manual_Revised_V1 0 Page 6 11 2 3 1 SDS plus SDS plus SDS plus 2 SDS plus SDS plus 3...

Page 23: ...Manual_Revised_V1 0 Page 22...

Page 24: ...Page 23 Manual_Revised_V1 0...

Page 25: ...Manual_Revised_V1 0 Page 24...

Page 26: ...Page 25 Manual_Revised_V1 0...

Page 27: ......