6

FIG. 5

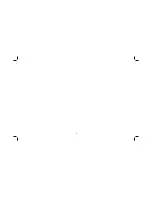

FIG. 4

KEYLESS CHUCK REMOVAL (FIG. 4)

Tighten the chuck around the shorter end of a hex key (not supplied) of 6 mm (1/4")

or greater size. Using a soft hammer or piece of wood, strike the longer end in the

counterclockwise direction. This will loosen the chuck so that it can be unscrewed by

hand.

KEYLESS CHUCK INSTALLATION (FIG. 5)

Screw the chuck on by hand as far as it will go. Tighten the chuck around the shorter

end of a 6 mm (1/4") or larger hex key (not supplied) strike the longer end in the

clockwise direction with a soft hammer.

Keyed Chuck – D21002

Open the chuck jaws by turning collar by hand and insert the shank of the bit about

19 mm (3/4") into chuck. Tighten the chuck collar by hand. Place chuck key in each of

the three holes, and tighten in clockwise direction. It’s important to tighten chuck with

all three holes. To release the bit, turn the chuck counterclockwise in just one hole, then

loosen the chuck by hand.

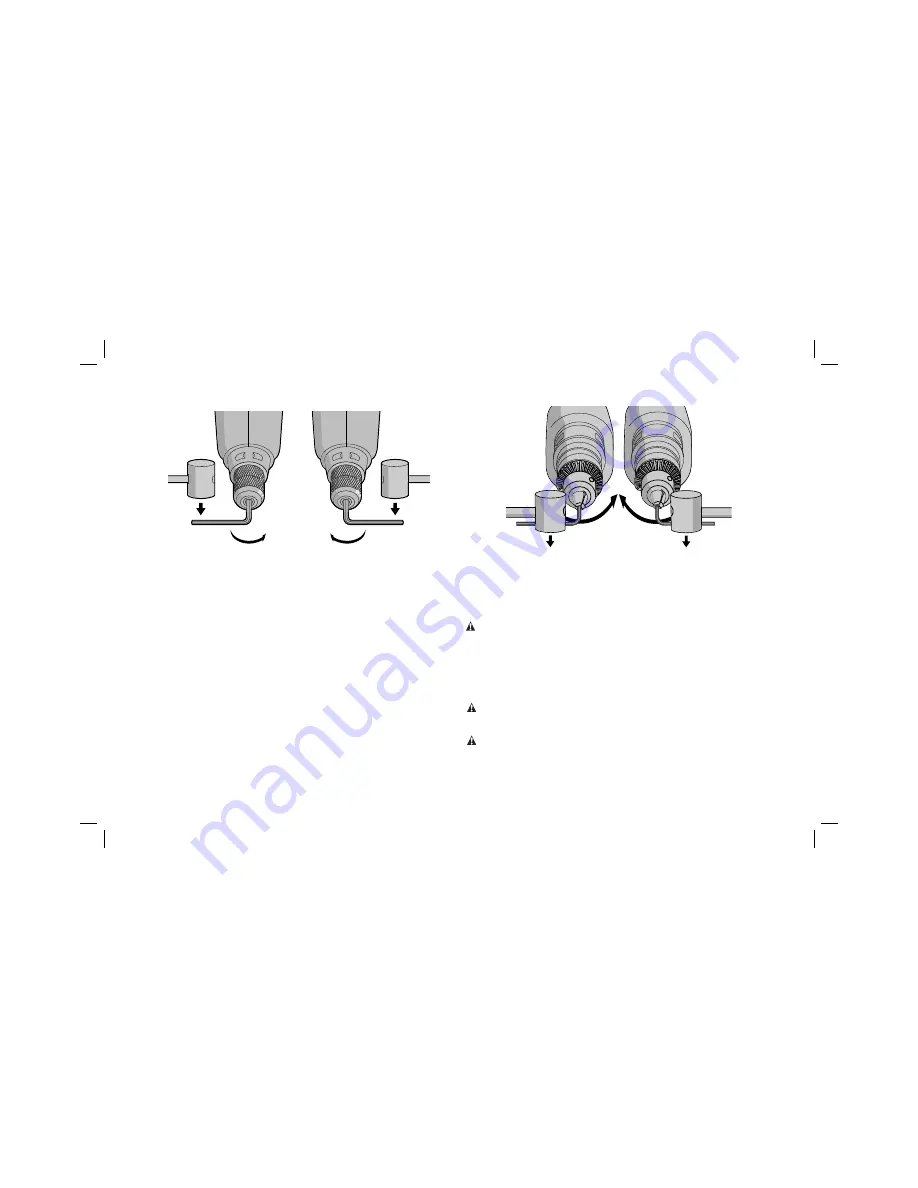

REMOVAL OF KEYED CHUCK (FIG. 6)

Tighten the chuck around the shorter end of a hex key (not supplied) of 6 mm (1/4")

or greater size. Using a soft hammer, strike the key sharply in the counterclockwise

direction when viewed from the front of the tool. This will loosen the chuck so that it

can be removed by hand.

FIG. 6

FIG. 7

KEYED CHUCK INSTALLATION (FIG. 7)

Screw the chuck on by hand as far as it will go. Insert the shorter end of a hex key

(not supplied) of 6 mm (1/4") or greater size and strike it in the clockwise direction

with a soft hammer.

MAINTENANCE

WARNING: Shock Hazard. To reduce the risk of serious personal injury, turn

tool off and disconnect from power source before making any adjustments or

removing/installing attachments or accessories.

Lubrication

Your power tool requires no additional lubrication.

Cleaning

WARNING:

Blow dirt and dust out of all air vents with clean, dry air at least once

a week. To minimize the risk of eye injury, always wear ANSI Z87.1 approved eye

protection when performing this.

WARNING:

Never use solvents or other harsh chemicals for cleaning the

non-metallic parts of the tool. These chemicals may weaken the plastic materials

used in these parts. Use a cloth dampened only with water and mild soap. Never let

any liquid get inside the tool; never immerse any part of the tool into a liquid.

Summary of Contents for D21002-XE

Page 1: ...D21002 XE D21008 XE DRILL INSTRUCTION MANUAL ...

Page 2: ......

Page 10: ...8 ...

Page 11: ...9 ...