5

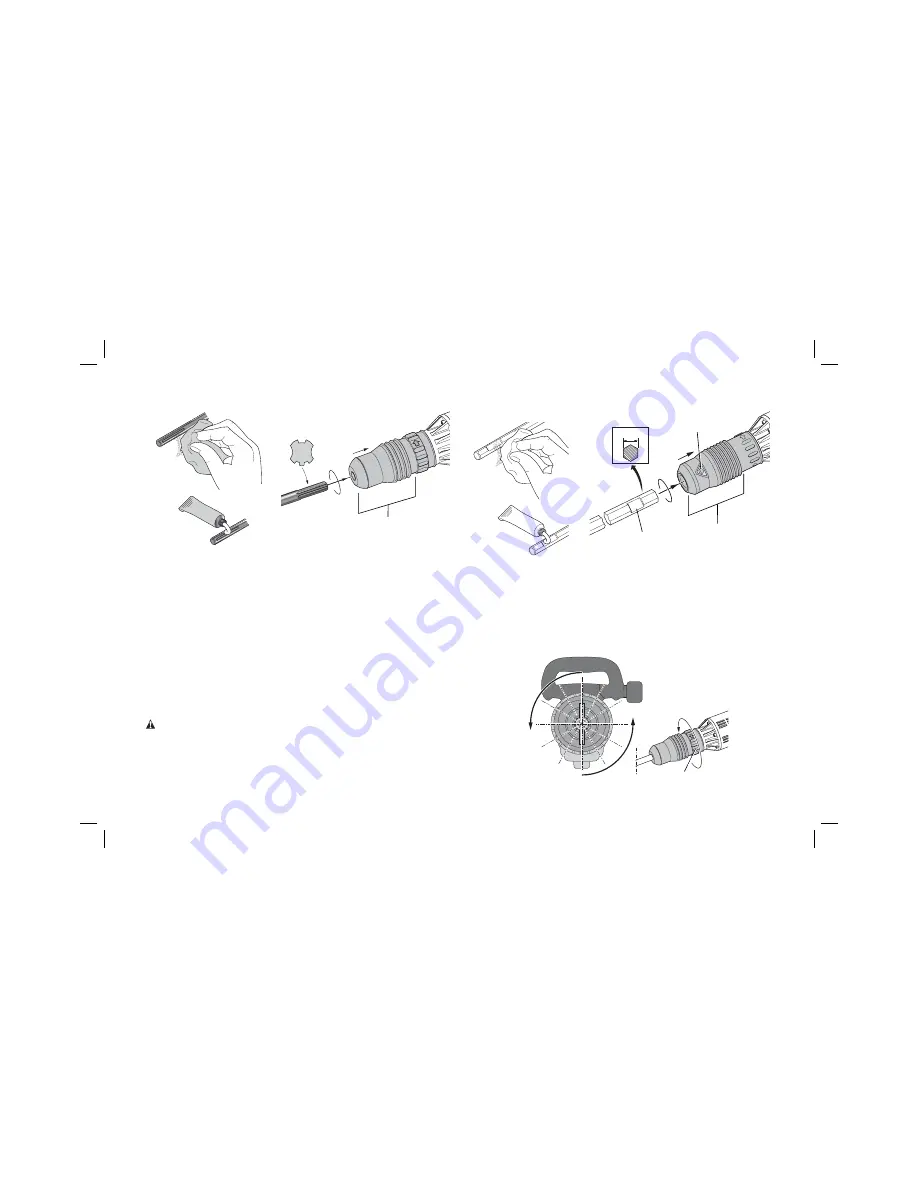

FIG. 3

D25901

E

FIG. 2

D25901

2. Insert the chisel shank into the tool holder/sleeve (E). Press and turn the chisel

slightly until the sleeve snaps into position.

3. Pull on the chisel to check if it is properly locked. The hammering function

requires the chisel to be able to move axially several centimeters when locked in

the tool holder.

4. To remove a chisel, pull back the tool holder/sleeve (E) and pull the chisel out of

the tool holder.

Inserting and Removing 19 mm Hex Accessories

CAUTION:

To reduce the risk of tool damage, only use 19 mm (3/4

"

) hex shank

accessories with the D25941.

D25941 (FIG. 4, 5)

This machine uses chisels with a 19 mm hex shank (refer to the inset in Figure 5

for a cross-section of a chisel shank).

1. Clean and grease the chisel shank.

CAUTION:

Do not apply lubricant to the machine.

2. Pull back the tool holder/sleeve (E), align the groove (G) with the yellow marker

(H) and insert the chisel shank into the tool holder. Release the locking sleeve.

3. Pull on the chisel to check if it is properly locked. The hammering function

requires the chisel to be able to move axially several centimetres when locked in

the tool holder.

FIG. 4

D25941

19 mm

FIG. 5

G

H

D25941

E

4. To remove a chisel, pull back the tool holder/sleeve (E) and pull the chisel out of

the tool holder.

Indexing the Chisel Position (Fig. 6)

The chisel can be indexed and locked into 12 different positions.

1. Insert the chisel as described above.

2. Rotate the chisel position collar (D) in the direction of the arrow until the chisel is

in the desired position.

D

FIG. 6

Summary of Contents for D25901-XE

Page 1: ...D25901 XE D25941 XE DEMOLITION HAMMERS INSTRUCTION MANUAL ...

Page 2: ...FIG 1 C D25901 D E B A F D25941 D E B A ...

Page 10: ...8 ...

Page 11: ...9 ...