4

WARNING:

Never load nails with the contact trip or trigger activated.

Personal injury may result.

1. Lock OFF trigger.

2. Disconnect the air supply from the tool.

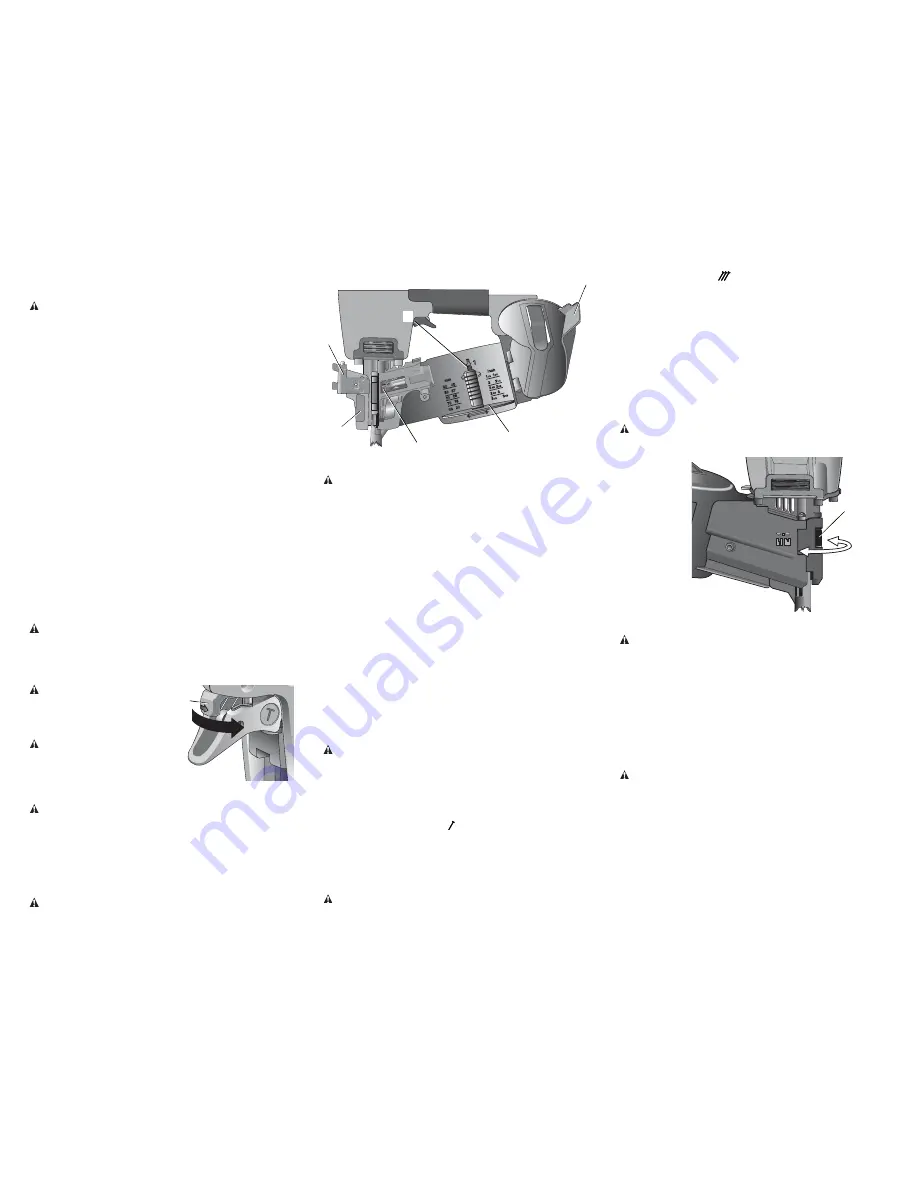

3. Pull the door latch (L) to open the door (K).

4. Rotate the canister door (H) open.

5. Adjust the nail platform (I) to properly accommodate the nail length

being used.

Pull up on the nail platform (I) for shorter nails.

Push in the nail platform adjustment button (G) and push down on the

nail platform (I) for longer nails.

6. Place the coil on the nail platform (I).

7. Uncoil enough nails [approximately 3" (8 cm)] to reach the nose of the

tool.

8. Insert the first nail into the nose and the second nail between the two

rails of the feed pawl (J).

NOTE:

Be careful not to deform the coil of nails during the loading process.

Otherwise, the nail guide door will not close and the nails might not feed

consistently.

9. Close the canister door (H) completely.

10. Close the door (K) making sure the door latch (L) is completely

engaged.

Actuating Tool

WARNING:

To reduce the risk of injury,

ALWAYS

wear proper eye [ANSI

Z87.1 (CAN/CSA Z94.3)] and hearing protection [ANSI S12.6 (S3.19)]

when operating this tool.

The tool can be actuated using one of two modes: single sequential action

trigger mode and bump action trigger mode. The trigger installed on the tool

as described in the

Trigger

section of this manual determines the mode of

operation.

SEQUENTIAL ACTION TRIGGER -

(GRAY)

The sequential action trigger’s intended use is for intermittent nailing where

very careful and accurate placement is desired.

To operate the nailer in sequential action mode:

1. Depress the contact trip firmly against the work surface.

2. Depress the trigger.

WARNING:

A nail will fire each time the trigger is depressed as long as

the contact trip remains depressed.

BUMP ACTION TRIGGER -

(BLACK)

The bump action trigger’s intended use is for rapid nailing on flat, stationary

surfaces.

Using the bump action trigger, two methods are available:

place actuation

and

bump actuation

.

To operate the tool using the PLACE ACTUATION method:

1. Depress the contact trip against the work surface.

2. Depress the trigger.

To operate the tool using the BUMP ACTUATION method:

1. Depress the trigger.

2. Push the contact trip against the work surface. As long as the trigger

is depressed, the tool will fire a nail every time the contact trip is

depressed. This allows the user to drive multiple nails in sequence.

WARNING:

Do not keep trigger depressed when tool is not in use. Keep

the lock-off switch rotated to the right (OFF) when the tool is not in use.

FIG. 5

M

Adjusting Depth (Fig. 5)

WARNING: To reduce risk of serious injury from accidental actuation

when attempting to adjust depth,

ALWAYS:

• Lock OFF trigger.

• Disconnect air supply.

• Avoid contact with trigger during adjustments.

The depth that the fastener is driven can be adjusted using the depth

adjustment next to the trigger of the tool.

1. To drive the nail shallower, rotate the depth setting wheel (M) to the

right.

2. To drive a nail deeper, rotate the depth setting wheel (M) to the left.

Clearing a Jammed Nail (Fig. 4)

WARNING

: Lock off trigger, disconnect air line from tool and remove

fasteners from magazine before making adjustments or personal injury may

result.

If a nail becomes jammed in the nosepiece, keep the tool pointed away

from you and follow these instructions to clear:

1. Lock OFF trigger.

2. Disconnect the air supply from the tool.

3. Open the door (K).

4. Open the canister door (H).

5. Remove the jammed nail.

6. Correct any deformation that may have occurred to the nail coil.

NOTE:

Should nails continue to jam frequently in nosepiece, have tool

serviced by an authorized D

E

WALT service center.

OPERATION

Preparing the Tool

WARNING:

Read the section titled

Important Safety Instructions for

Pneumatic Tools

at the beginning of this manual. Always wear eye and ear

protection when operating this tool. Keep the nailer pointed away from

yourself and others. For safe operation, complete the following procedures

and checks before each use of the nailer.

CAUTION:

To reduce the risk of damage to the tool, only use D

E

WALT

Pneumatic Tool Oil or a non-detergent S.A.E. 20 weight oil. Oil with

additives or detergent will damage tool parts.

1. Before you use the nailer, be sure that the compressor tanks have been

properly drained.

2. Lubricate tool:

a.

Use

D

E

WALT Pneumatic Tool Oil or a non-detergent S.A.E. 20 weight

oil. DO NOT use detergent oil or additives as they will damage O-rings

and rubber parts.

b. Use a filter and regulator when possible.

c. Add 5 to 7 drops of oil in the air fitting a least twice a day.

3. Wear eye and ear protection.

4. Ensure canister is empty of all fasteners.

5. Check for smooth and proper operation of contact trip. Do not use tool

if assembly is not functioning properly. NEVER tamper with the contact

trip. NEVER use a tool that has the contact trip restrained in the actuated

position.

6. Check air supply: Ensure air pressure does not exceed recommended

operating limits; 70 to 120 psi, (4.9 to 8.3 bar, 5 to 8.5 kg/cm

2

).

7. Keep tool pointed away from yourself and others.

8. Lock off trigger.

9. Connect air hose.

10. Check for audible leaks around valves and gaskets. Never use a tool that

leaks or has damaged parts.

WARNING:

To reduce the risk of personal injury, disconnect tool from

air supply before performing maintenance, clearing a jammed fastener,

leaving work area, moving tool to another location or handing the tool to

another person.

Using the Lock-off (Fig. 3)

F

FIG. 3

WARNING:

To reduce the risk of

injury,

ALWAYS

wear proper eye

[ANSI Z87.1 (CAN/CSA Z94.3)] and

hearing protection [ANSI S12.6

(S3.19)] when operating this tool.

WARNING:

Do not keep trigger

depressed when tool is not in use.

Keep the lock-off switch rotated to

the right (OFF) when the tool is not in

use. Serious personal injury may

result.

WARNING:

Lock off trigger, disconnect air line from tool and remove

fasteners from magazine before making adjustments or personal injury

may result.

Each D

E

WALT nailer is equipped with a trigger lock-off switch (F) which

when rotated to the right, prevents the tool from actuating. When the switch

is centered, the tool will be fully operational. The trigger should always be

locked off whenever any adjustments are made or when tool is not in use.

Loading the Tool (Fig. 4)

WARNING:

Keep the tool pointed away from yourself and others. Serious

personal injury may result.

FIG. 4

K

G

H

I

L

J