D

E

WALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 (DEC06) Form No. 635693-00 Copyright © 2006 D

E

WALT

The following are trademarks for one or more D

E

WALT power tools: the yellow and black color scheme; the “D” shaped air intake grill; the array of

pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

IF YOU HAVE ANY QUESTIONS OR COMMENTS CALL US TOLL

FREE AT:

1-800-4-D

E

WALT (1-800-433-9258)

JAW REPLACEMENT INSTRUCTIONS

DC495

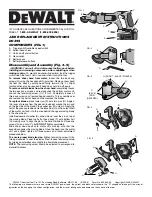

COMPONENTS (FIG. 1)

A. Trigger switch/variable speed switch

B. Swivel head shear

C. On/Lock-off control button

D. Hex wrench

E. Battery pack

F. Battery release buttons

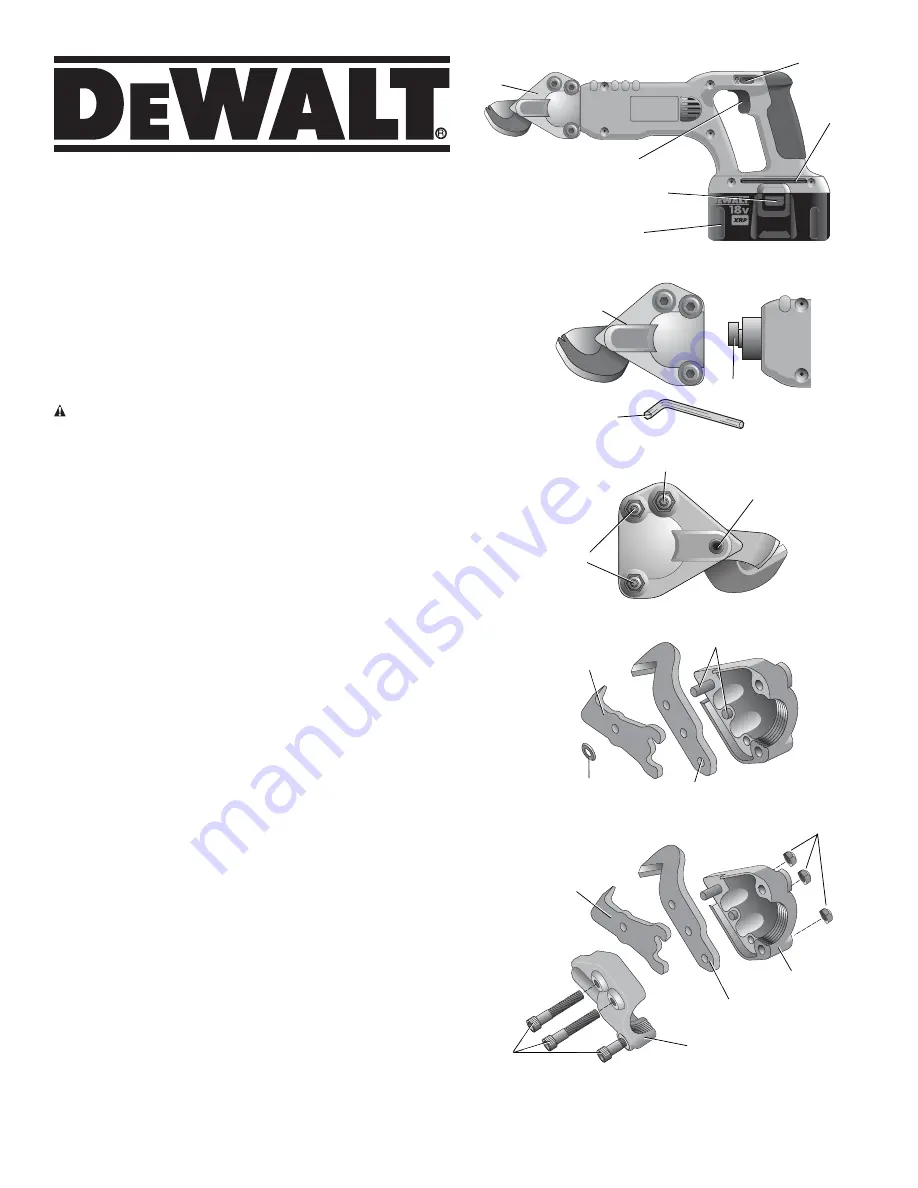

Disassembly and Assembly (Fig. 2–5)

WARNING: Turn unit off and disconnect battery pack before

installing and removing accessories, before adjusting or when

making repairs.

To prevent inadvertant operation, lock the trigger

switch when the tool is not in use and when storing the tool.

To remove shear head from motor,

loosen the two back cap

screws (G) using the hex wrench (D) provided. Remove shear head

(B) from the body by pulling head firmly forward (Fig. 2). Slight

twisting action may be required if head does not slide off easily.

To remove cutter blades from the shear head,

completely loosen

the two back cap screws and remove shear head from motor unit.

Loosen the tensioning screw (O) 1/2 turn. Completely loosen all

three cap screws and remove head assembly. Turn assembly over

and remove top half of head and then remove the blades.

To replace blades,

place lower jaw (P) onto two pins (R). Apply a

thin layer of grease from the packet (included) around the pin and

on the top side of the blade. Place upper jaw (Q) onto pin. Apply the

rest of the grease provided onto the eccentric (L) on the output shaft

of the motor unit and into the area behind the upper moving blade

in the shear head.

Install replacement washer (S), cone side up, over the pin on top of

the moving blade. Place top half of head back (T) onto bottom half

(U), making sure to align the pin to the hole. Reinstall all three cap

screws (G) and nuts (V), but

DO NOT

tighten completely.

Slide shear head back onto motor unit, making sure that the

eccentric engages the moving blade. Once the head is on the motor

unit and aligned, tighten all three screws and follow adjustment

procedure below.

To ensure proper blade tension,

tighten tensioning screw (O) by

turning clockwise to seat the blades. Next, loosen tensioning screw

by turning counterclockwise slightly to allow blade movement.

NOTE

: The tensioning screw should be adjusted to correspond to

material thickness.

A

E

B

C

D

F

L

FIG. 2

B

D

G

(BACK)

(DOS)

(REVERSO)

G (FRONT / AVANT / FRENTE)

O

FIG. 3

FIG. 5

N

G

P

Q

T

U

FIG. 1

FIG. 4

S

P

Q

R