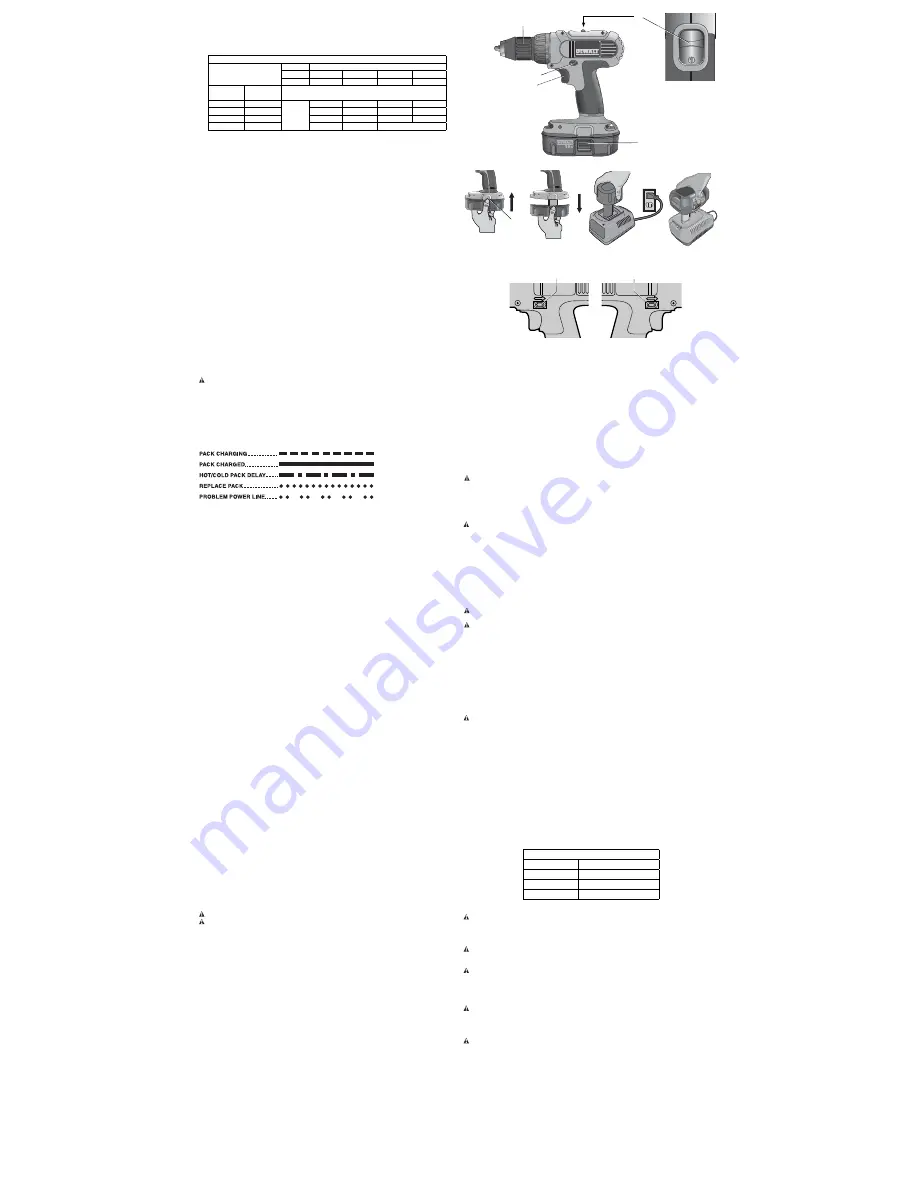

Dual Range Gearing (Fig. 1)

The dual range feature of your driver/drill allows you to shift gears for greater versatility.

To select the low speed, high torque setting, turn the tool off and permit to stop. Slide the gear shifter

(D) forward (towards the chuck). To select the high speed, low torque setting, turn the tool off and

permit to stop. Slide the gear shifter back (away from chuck).

NOTE:

Do not change gears when the tool is running. If you are having trouble changing gears,

make sure that the dual range gear shifter is either completely pushed forward or completely

pushed back.

Keyless Single Sleeve Chuck

Your tool features a keyless chuck with one rotating sleeve for one-handed operation of the chuck. To

insert a drill bit or other accessory, follow these steps.

1. Lock the trigger in the OFF position as previously described.

2. Grasp the black sleeve of the chuck with one hand and use the other hand to secure the tool.

Rotate the sleeve counterclockwise far enough to accept the desired accessory.

3. Insert the accessory about 3/4" (19 mm) into the chuck and tighten securely by rotating the chuck

sleeve clockwise with one hand while holding the tool with the other. Your tool is equipped with an

automatic spindle lock mechanism. This allows you to open and close the chuck with one hand.

To release the accessory, repeat step 2 above.

WARNING:

Do not attempt to tighten drill bits (or any other accessory) by gripping the front part of

the chuck and turning the tool on. Damage to the chuck and personal injury may result. Always lock

off trigger switch when changing acces sories.

Be sure to tighten chuck with one hand on the chuck sleeve and one hand holding the tool for

maximum tightness.

OPERATION

WARNING: To reduce the risk of serious personal injury, turn tool off and remove the

battery pack before making any adjustments or removing/installing attachments or

accessories.

An accidental start-up can cause injury.

Installing and Removing the Battery Pack (Fig. 2)

NOTE:

Make sure your battery pack is fully charged.

To install the battery pack into the tool handle

, align the notch inside the tool’s handle with the

battery pack and slide the battery pack firmly into the handle until you hear the lock snap into place.

To remove the battery pack from the tool

, press the release buttons (E) and firmly pull the

battery pack out of the tool handle. Insert it into the charger as described in the charger section of

this manual.

Drill Operation

WARNING:

To reduce the risk of serious personal injury, turn tool off and disconnect tool from

power source before making any adjustments or removing/installing attachments or accessories.

WARNING: To reduce the risk of personal injury, ALWAYS

ensure workpiece is anchored

or clamped firmly. If drilling thin material, use a wood “back-up” block to prevent damage to the

material.

Turn the collar to the drill bit symbol for drilling. Select the desired speed/torque range using the gear

shifter to match the speed and torque to the planned operation.

1. Use sharp drill bits only. For WOOD, use the low speed setting and twist drill bits, spade bits,

power auger bits, or hole saws. For METAL, use the low speed setting and steel twist drill bits

or hole saws. For MASONRY, such as brick, cement, cinder block, etc., use carbide-tipped

bits. Use low speed for bits greater than 3/8" (10 mm).

2. Always apply pressure in a straight line with the bit. Use enough pressure to keep drill biting,

but do not push hard enough to stall the motor or deflect the bit.

3. Hold tool firmly with both hands to control the twisting action of the drill. If model is not equipped

with side handle, grip drill with one hand on the handle and one hand on the battery pack.

CAUTION:

Drill may stall if overloaded causing a sudden twist. Always expect the stall. Grip the

drill firmly to control the twisting action and avoid injury.

4.

IF DRILL STALLS,

it is usually because it is being overloaded or improperly used.

RELEASE

TRIGGER IMMEDIATELY,

remove drill bit from work, and determine cause of stalling.

DO

NOT CLICK TRIGGER ON AND OFF IN AN ATTEMPT TO START A STALLED DRILL —

THIS CAN DAMAGE THE DRILL.

5. To minimize stalling or breaking through the material, reduce pressure on drill and ease the bit

through the last fractional part of the hole.

6. Keep the motor running when pulling the bit back out of a drilled hole. This will help prevent

jamming.

7. With variable speed drills there is no need to center punch the point to be drilled. Use a slow

speed to start the hole and accelerate by squeezing the trigger harder when the hole is deep

enough to drill without the bit skipping out.

Operation as a Screwdriver

Select the desired speed/torque range using the dual range gear shifter on the top of tool to match

the speed and torque to the planned operation.

Insert the desired fastener accessory into the chuck as you would any drill bit. Make a few practice

runs in scrap or unseen areas to determine the proper position of the clutch collar.

MAXIMUM RECOMMENDED CAPACITIES

DC759, DC970

WOOD

1-1/2"

STEEL

1/2"

MASONRY

1/4"

MAINTENANCE

WARNING: To reduce the risk of serious personal injury, turn tool off and remove the

battery pack before making any adjustments or removing/installing attachments or

accessories.

An accidental start-up can cause injury.

Cleaning

WARNING:

Blow dirt and dust out of all air vents with clean, dry air at least once a week. To

minimize the risk of eye injury, always wear ANSI Z87.1 approved eye protection when performing

this.

WARNING:

Never use solvents or other harsh chemicals for cleaning the non-metallic parts

of the tool. These chemicals may weaken the plastic materials used in these parts. Use a cloth

dampened only with water and mild soap. Never let any liquid get inside the tool; never immerse

any part of the tool into a liquid.

CHARGER CLEANING INSTRUCTIONS

WARNING:

Shock hazard. Disconnect the charger from the AC outlet before cleaning. Dirt and

grease may be removed from the exterior of the charger using a cloth or soft non-metallic brush.

Do not use water or any cleaning solutions.

Accessories

WARNING:

Since accessories, other than those offered by D

E

WALT, have not been tested with

this product, use of such accessories with this tool could be hazardous. To reduce the risk of injury,

only D

E

WALT recommended accessories should be used with this product.

Recommended accessories for use with your tool are available at extra cost from your local dealer or

authorized service center. If you need assistance in locating any accessory, please contact D

E

WALT

Industrial Tool Co., 701 East Joppa Road, Towson, MD 21286, call 1-800-4-D

E

WALT (1-800-433-

9258) or visit our website: www.dewalt.com.

Repairs

The charger and battery pack are not serviceable.

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including brush

inspection and replacement) should be performed by a D

E

WALT factory service center, a D

E

WALT

authorized service center or other qualified service personnel. Always use identical replacement

parts.

Register Online

Thank you for your purchase. Register your product now for:

•

WARRANTY SERVICE:

Registering your product will help you obtain more efficient warranty

service in case there is a problem with your product.

16 gauge has more capacity than 18 gauge. An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. When using more than one extension to make up

the total length, be sure each individual extension contains at least the minimum wire size. The

following table shows the correct size to use depending on cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier the

cord.

Minimum Gauge for Cord Sets

Ampere Rating

Volts

Total Length of Cord in Feet (meters)

120V

25 (7.6)

50 (15.2)

100 (30.5)

150 (45.7)

240V

50 (15.2)

100 (30.5)

200 (61.0)

300 (91.4)

More

Than

Not More

Than

AWG

0

6

18

16

16

14

6

10

18

16

14

12

10

12

16

16

14

12

12

16

14

12

Not Recommended

•

Do not place any object on top of charger or place the charger on a soft surface that

might block the ventilation slots and result in excessive internal heat.

Place the charger

in a position away from any heat source. The charger is ventilated through slots in the top and

the bottom of the housing.

•

Do not operate charger with damaged cord or plug

.

•

Do not operate charger if it has received a sharp blow, been dropped, or otherwise

damaged in any way.

Take it to an authorized service center.

•

Do not disassemble charger; take it to an authorized service center when service or

repair is required.

Incorrect reassembly may result in a risk of electric shock, electrocution or fire.

•

Disconnect the charger from the outlet before attempting any cleaning. This will

reduce the risk of electric shock.

Removing the battery pack will not reduce this risk.

•

NEVER

attempt to connect two chargers together.

•

The charger is designed to operate on standard 120 volt household electrical power.

Do not attempt to use it on any other voltage.

This does not apply to the vehicular charger.

Using Automatic Tune-Up™ Mode

The automatic Tune-Up™ Mode equalizes or balances the individual cells in the battery pack

allowing it to function at peak capacity. Battery packs should be tuned up weekly or after

10 charge/discharge cycles or whenever the pack no longer delivers the same amount of work. To

use the automatic Tune-Up™, place the battery pack in the charger and leave it for at least 8 hours.

The charger will cycle through the following modes.

1. The red light will blink continuously indicating that the 1-hour charge cycle has started.

2. When the 1-hour charge cycle is complete, the light will stay on continuously and will no longer

blink. This indicates that the pack is fully charged and can be used at this time.

3. If the pack is left in the charger after the initial 1-hour charge, the charger will begin the

Automatic Tune-Up™ mode. This mode continues up to 8 hours or until the individual cells in

the battery pack are equalized. The battery pack is ready for use and can be removed at any

time during the Automatic Tune-Up™ mode.

4. Once the Automatic Tune-Up™ mode is complete, the charger will begin a maintenance

charge; the red indicator will remain lit.

Chargers

Your tool uses a D

E

WALT charger. Be sure to read all safety instructions before using your charger.

Consult the chart at the end of this manual for compatibility of chargers and battery packs.

Charging Procedure (Fig. 3)

DANGER:

Electrocution hazard. 120 volts are present at charging terminals. Do not probe with

conductive objects. Electric shock or electrocution may result.

1. Plug the charger into an appropriate outlet before inserting battery pack.

2. Insert the battery pack into the charger, as shown in Figure 3, making sure the pack is fully

seated in charger. The red (charging) light will blink continuously indicating that the charging

process has started.

3. The completion of charge will be indicated by the red light remaining on continuously. The pack

is fully charged and may be used at this time or left in the charger.

Indicator Light Operation

Charge Indicators

Some chargers are designed to detect certain problems that can arise with battery packs.

Problems are indicated by the red light flashing at a fast rate. If this occurs, re-insert battery pack

into the charger. If the problem persists, try a different battery pack to determine if the charger is

OK. If the new pack charges correctly, then the original pack is defective and should be returned to

a service center or other collection site for recycling. If the new battery pack elicits the same trouble

indication as the original, have the charger tested at an authorized service center.

HOT/COLD PACK DELAY

Some chargers have a Hot/Cold Pack Delay feature: when the charger detects a battery that is

hot, it automatically starts a Hot Pack Delay, suspending charging until the battery has cooled.

After the battery has cooled, the charger automatically switches to the Pack Charging mode. This

feature ensures maximum battery life. The red light flashes long, then short while in the Hot Pack

Delay mode.

PROBLEM POWER LINE

Some chargers have a Problem Power Line indicator. When the charger is used with some portable

power sources such as generators or sources that convert DC to AC, the charger may temporarily

suspend operation,

flashing the red light with two fast blinks followed by a pause

. This

indicates the power source is out of limits.

LEAVING THE BATTERY PACK IN THE CHARGER

The charger and battery pack can be left connected with the red light glowing indefinitely. The

charger will keep the battery pack fresh and fully charged.

NOTE:

A battery pack will slowly lose its charge when kept out of the charger. If the battery pack

has not been kept on maintenance charge, it may need to be recharged before use. A battery pack

may also slowly lose its charge if left in a charger that is not plugged into an appropriate AC source.

WEAK BATTERY PACKS:

Chargers can also detect a weak battery pack. Such batteries are still

usable but should not be expected to perform as much work. The charger will indicate to replace

battery pack.

Important Charging Notes

1. Longest life and best performance can be obtained if the battery pack is charged when the air

temperature is between 65 °F and 75 °F (18 °–24 °C). DO NOT charge the battery pack in an

air temperature below +40 °F (+4.5 °C), or above +104 °F (+40°C). This is important and will

prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch while charging. This is a normal

condition, and does not indicate a problem. To facilitate the cooling of the battery pack after

use, avoid placing the charger or battery pack in a warm environment such as in a metal shed,

or an uninsulated trailer.

3. If the battery pack does not charge properly:

a.

Check operation of receptacle by plugging in a lamp or other appliance;

b.

Check to see if receptacle is connected to a light switch which turns power off when you turn

out the lights;

c.

Move charger and battery pack to a location where the surrounding air temperature is

approximately 65 °F–75 °F (18 °– 24 °C);

d.

If charging problems persist, take the tool, battery pack and charger to your local service

center.

4. The battery pack should be recharged when it fails to produce sufficient power on jobs which

were easily done previously. DO NOT CONTINUE to use under these conditions. Follow the

charging procedure. You may also charge a partially used pack whenever you desire with no

adverse affect on the battery pack.

5. Under certain conditions, with the charger plugged into the power supply, the exposed

charging contacts inside the charger can be shorted by foreign material. Foreign materials of a

conductive nature such as, but not limited to, grinding dust, metal chips, steel wool, aluminum

foil, or any buildup of metallic particles should be kept away from charger cavities. Always

unplug the charger from the power supply when there is no battery pack in the cavity. Unplug

charger before attempting to clean.

6. Do not freeze or immerse charger in water or any other liquid.

WARNING:

Shock hazard. Don’t allow any liquid to get inside charger. Electric shock may result.

WARNING:

Burn hazard. Never attempt to open the battery pack for any reason. If the plastic

housing of the battery pack breaks or cracks, return to a service center for recycling.

Storage Recommendations

1. The best storage place is one that is cool and dry away from direct sunlight and excess heat

or cold.

2. For long storage, it is recommended to store a fully charged battery pack in a cool dry place

out of the charger for optimal results.

NOTE:

Battery packs should not be stored completely depleted of charge. The battery pack will

need to be recharged before use.

SAVE THESE INSTRUCTIONS FOR FUTURE USE

COMPONENTS

Variable Speed Switch (Fig. 1)

To turn the tool on

, squeeze the trigger switch (A).

To turn the tool off,

release the trigger switch.

Your tool is equipped with a brake. The chuck will stop as soon as the trigger switch is fully released.

NOTE:

Continuous use in variable speed range is not recommended. It may damage the switch

and should be avoided.

Forward/Reverse Control Button (Fig. 1, 4)

A forward/reverse control button (B) determines the direction of the tool and also serves as a lock off

button. To select forward rotation, release the trigger switch and depress the forward/reverse control

button on the right side of the tool. To select reverse, depress the forward/reverse control button on

the left side of the tool. The center position of the control button locks the tool in the off position. When

changing the position of the control button, be sure the trigger is released.

NOTE:

The first time the tool is run after changing the direction of rotation, you may hear a click on start

up. This is normal and does not indicate a problem.

Torque Adjustment Collar (Fig. 1)

The torque adjustment collar (C) is clearly marked with numbers and a drill bit symbol.The collar should

be rotated until the desired setting is located at the top of the tool (Fig. 1). Locators are provided in the

collar to eliminate the guess work when selecting fastening torque. The higher the number on the collar,

the higher the torque and the larger the fastener which can be driven. To lock the clutch for drilling

operations, move to the drill bit position.

NOTE:

When using the drill/driver for drilling holes, be sure that the torque adjusting collar is set so

the figure of the drill is aligned with the center line on the top of the tool. Failure to do this will allow the

clutch to slip while attempting to drill.

FIG. 4

DEPRESS FOR REVERSE

ENFONCER POUR LA

ROTATION ARRIÈRE

ADELANTE

DEPRESS FOR FORWARD

ENFONCER POUR LA

ROTATION AVANT

ATRÁS

FIG. 1

FIG. 3

FIG. 2

E

D

A

B

C

E