20

English

Glossary

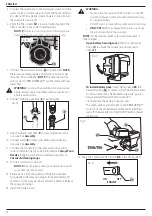

Bypass mode:

Allows water to re-circulate within pump when

the engine is running and the spray gun trigger is not pulled.

Chemical/soap hose:

Feeds chemical/cleaning soap

into the pump to mix with the water. Refer to

Chemicals/

Cleaning soaps

section.

Chemical injection system:

Mixes chemical/cleaning soap

with water to improve cleaning effectiveness.

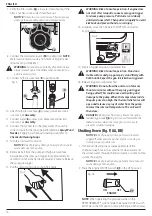

Choke control:

Opens and closes carburetor choke valve.

nOTE:

The choke adjust automatically when operating in the

PRESSUREREADY® system mode, only adjuste the choke when

operating in Manual Mode.

CU:

Cleaning Units. GPM multiplied by psi. (GPM x PSI = CU)

Fuel valve lever:

Opens/closes connection between fuel tank

and carburetor.

gPM*

: Gallons Per Minute. The unit of measure for the flow rate

of water.

Psi*:

Pounds per Square Inch. The unit of measure for water

pressure. Also used for air pressure, hydraulic pressure, etc.

* Complies with CETA Performance Standard CPC-100. Values are

within manufacturing tolerance of +/- 10%.

Troubleshooting Guide

This section provides a list of the more frequently encountered malfunctions, their causes and corrective actions. The operator or

maintenance personnel can perform some corrective actions, and others may require assistance, contact us at: AUST 1800 841 749 /

NZ 0800 467 813 for assistance.

Problem

Troubleshooting Key #

Engine will not start

1, 2, 3, 4, 5, 6, 7, 8, 10, 16, 29, 30

(refer to the engine's instruction manual for further engine troubleshooting)

No or low pressure (initial use)

9, 10, 11, 12, 13, 14, 15, 16

Will not draw chemical/cleaning soaps

16, 17, 18, 19, 20, 21

No or low pressure (after period of normal use)

22, 23, 24

Water leaking at gun/spray wand connection

25, 26

Water leaking at pump

25, 26, 27, 28

Pump Pulsates

12

Troubleshooting Key #

Key #

POssiBlE CAUsE

POssiBlE sOlUTiOn

1

No fuel.

Add fuel.

2

Low or no oil.

NOTE:

This pressure washer is equipped with a low oil sensor. If the

oil is low or the unit is not level the unit will shut off or fail to start.

Add required amount of oil.

Ensure the pressure washer is placed on a level surface.

3

Manual mode only:

Pressure builds up after two pulls on the

recoil starter or after initial use.

Squeeze spray gun trigger to relieve pres sure.

4

Choke in the OPEN position.

Move choke to the CLOSED po si tion.

5

Spark plug wire not attached.

Attach spark plug wire.

6

Engine ON/OFF switch in OFF po si tion.

Place engine ON/OFF switch in ON position.

kPa (kilopascal):

Metric pressure measurement. 1 kilopascal

equal 1000 pascals.

Quick-connect spray wand:

Allows the user to quickly change

out high pressure nozzles. Refer to

spray Wand nozzles

.

Thermal relief valve (Manual mode only):

When the

temperature inside the pump rises too high the valve will open

and release a gush of water in an effort to lower the temperature

inside the pump. The valve will then close.

Cold water supply:

All pressure washers must have a source of

cold water. The minimum requirements for a water supply are 20

psi (138 kPa) and 5 gallons per minute.

PREssUREADY® system mode:

This mode uses an advanced

electronic system to stop and start the pressure washer

when the spray gun trigger is squeezed and released. The

PRESSUREADY® system also communicates with the user

through fault codes to help diagnose and solve issues with the

pressure washer.

Manual mode:

This mode starts the pressure washer without

the use of the battery and the PRESSUREADY® system.

Summary of Contents for DCB107

Page 1: ...145mm 210mm ...

Page 2: ...B Copyright DeWALT English original instructions 1 ...

Page 26: ...24 ...

Page 27: ...25 ...

Page 28: ...7113784 03 20 AUST 1800 841 749 NZ 0800 467 813 ...