12

GB

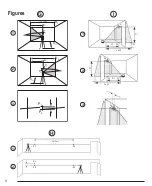

5.

Place the laser 2”–3” (5–8 cm) from the second wall. To test

the front laser dot, make sure the front of the laser is facing

the wall (Figure

K

#2), and adjust the height of the laser

until the laser dot hits point P2.

6.

Turn the laser 180˚ and aim the laser dot near point P1 on

the first wall, and mark point P3

(Figure

K

#2).

7.

Measure the vertical distance between points P1 and P3 on

the first wall.

8.

If your measurement is greater than the

Allowable

Distance Between P1 & P3

for the corresponding

Distance Between Walls

in the following table, the laser

must be serviced at an authorized service center.

Distance Between

Walls

Allowable Distance

Between P1 & P3

20′ (6.0m)

9/64” (3.6mm)

30′ (9.0m)

7/32” (5.4mm)

50′ (15.0m)

11/32” (9mm)

75′ (23.0m)

9/16” (13.8mm)

9.

Repeat steps 2 through 8 to check the accuracy of the right

dot and then the left dot, making sure that the laser dot you

are testing is the laser dot facing each wall.

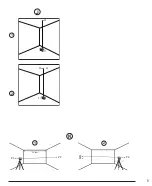

Level Dot Accuracy - Square

Checking the level calibration of the laser unit requires

a room

at least 35’ (10m) long

. A

ll marks can be made on the floor

by placing a target in front of the level or square beam and

transferring the location to the floor.

NOTE

:

To ensure accuracy, the distance (D1) from P1 to P2, P2

to P3, P2 to P4, and P2 to P5 should be equal.

1.

Mark point P1 on the floor at one end of the room, as

shown in Figure

L

#1.

2.

Turn the laser ON and press

once to display dots above,

ahead, and below the laser

.

3.

Place the laser so that the down dot is centered over point

P1 and make sure the front dot points toward the far end of

the room (Figure

L

#1).

4.

Using a target to transfer the front level dot location on the

wall to the floor, mark point P2 on the floor and then point P3

on the floor (Figure

L

#1).

5.

Move the laser

to point P2 and align the front level dot to

point P3 again (Figure

L

#2).

6.

Using a target to transfer the front level dot location on the

wall to the floor, mark the location of two square beams as

points P4 and P5 on the floor

(Figure

L

#2).

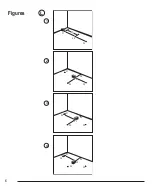

7.

Turn the laser

90° so the front level dot aligns to point P4

(Figure

L

#3).

8.

Mark the location of the first square beam as point P6 on

the floor as close as possible to point P1 (Figure

L

#3).

9.

Measure the

distance between points P1 and P6 (Figure

L

#3).

10.

If your

measurement is greater than the

Allowable

Distance Between P1 & P6

for the corresponding

Distance (D1)

in the following table, the laser must be

serviced at an authorized service center.

Distance (D1)

Allowable Distance Between

P1 & P6

25’ (7.5m)

3/32” (2.2mm)

30’ (9m)

7/64” (2.7mm)

50’ (15m)

3/16”(4.5mm)

11.

Turn the laser

180° so the front level dot aligns to point P5

(Figure

L

#4).

12.

Mark the location of the second square beam as point P7

on the floor as close as possible to point P1 (Figure

L

#4).

13.

Measure the

distance between points P1 and P7 (Figure

L

#4).

14.

If your

measurement is greater than the

Allowable

Distance Between P1 & P7

for the corresponding

Distance (D1)

in the following table, the laser must be

serviced at an authorized service center.

Distance (D1)

Allowable Distance Between

P1 & P7

25’ (7.5m)

3/32” (2.2mm)

30’ (9m)

7/64” (2.7mm)

50’ (15m)

3/16”(4.5mm)

Summary of Contents for DCE0825G

Page 1: ...DEWALT5DotCrossLineLaser DCE0825R DCE0825G GB NL GR I FIN D DK ES NO F SE PT TR www DEWALT eu ...

Page 2: ...1b 1a 3a 3b 3c 3d 3e 3f x3 x2 x1 x2 x3 x1 x2 Figures 2 1 2 A B C 1 2 1 4 20 5 8 11 3 3 ...

Page 3: ...3 D E F DCB121 DCB123 DCB127 ...

Page 5: ...5 J K P2 P2 P3 P1 P1 x x x x x 1 2 P1 P2 P3 P1 P2 x x x x x 20 6m 1 2 ...

Page 6: ...Figures 6 4 L P1 P2 P3 D1 P1 P2 P5 P4 P3 P1 P6 P2 P5 P4 P3 P7 P1 P6 P2 P5 P4 P3 1 2 3 ...