•

Make sure that cord is located so that it will not be stepped on, tripped over, or oth-

erwise subjected to damage or stress.

•

Do not use an extension cord unless it is absolutely necessary.

Use of improper exten-

sion cord could result in risk of fire, electric shock, or electrocution.

•

An extension cord must have adequate wire size (AWG or American Wire Gauge) for

safety.

The smaller the gauge number of the wire, the greater the capacity of the cable, that

is 16 gauge has more capacity than 18 gauge. When using more than one extension to

make up the total length, be sure each individual extension contains at least the minimum

wire size.

Recommended Minimum Wire Size for Extension Cords

Total Length of Cord

25 ft.

50 ft.

75 ft.

100 ft.

125 ft.

150 ft.

175 ft.

7.6 m 15.2 m

22.9 m

30.5 m

38.1 m 45.7 m

53.3 m

Wire Size AWG

18 18 16

16 14 14

12

•

Do not place any object on top of charger or place the charger on a soft surface that

might block the ventilation slots and result in excessive internal heat.

Place the charg-

er in a position away from any heat source. The charger is ventilated through slots in the

top and the bottom of the housing.

•

Do not operate charger with damaged cord or plug

— have them replaced immediately.

•

Do not operate charger if it has received a sharp blow, been dropped, or otherwise

damaged in any way.

Take it to an authorized service center.

•

Do not disassemble charger; take it to an authorized service center when service or

repair is required.

Incorrect reassembly may result in a risk of electric shock, electrocution

or fire.

•

Disconnect the charger from the outlet before attempting any cleaning. This will

reduce the risk of electric shock.

Removing the battery pack will not reduce this risk.

•

NEVER

attempt to connect 2 chargers together.

•

The charger is designed to operate on standard household electrical power (120

Volts). Do not attempt to use it on any other voltage.

This does not apply to the vehic-

ular charger.

Using Automatic Tune-Up™ Mode

The Automatic Tune-Up™ Mode equalizes or balances the individual cells in the battery pack

allowing it to function at peak capacity. Battery packs should be tuned up weekly or after 10

charge/discharge cycles or whenever the pack no longer delivers the same amount of work.

To use the Automatic Tune-Up™, place the battery pack in the charger and leave it for at least

8 hours. The charger will cycle through the following modes.

1. The red light will blink continuously indicating that the 1-hour charge cycle has started.

2. When the 1-hour charge cycle is complete, the light will stay on continuously and will no

longer blink. This indicates that the pack is fully charged and can be used at this time.

3. Whenever the pack is left in the charger after the initial 1-hour charge, the charger will begin

the Automatic Tune-Up™ Mode. This mode continues up to 8 hours or until the individual

cells in the battery pack are equalized. The battery pack is ready for use and can be

removed at any time during the Tune-Up™ Mode.

4. Once the Automatic Tune-Up™ Mode is complete the charger will transition to a main-

tenance charge; the indicator light shuts off when the Automatic Tune-Up™ Mode is

complete.

SAVE THESE INSTRUCTIONS

FOR FUTURE USE

Chargers

Your tool uses an 9.6-18 Volt D

E

WALT Charger. Your battery can be charged in D

E

WALT 1

Hour Chargers, 15 Minute Chargers or Vehicular 12 volt charger. Be sure to read all safety

instructions before using your charger. Consult the chart on the back cover of this manual for

compatibility of chargers and battery packs.

Charging Procedure

DANGER:

Electrocution hazard. 120 volts are present at charging terminals. Do not probe

with conductive objects.

1. Plug the charger into an appropriate outlet before inserting battery pack.

2. Insert the battery pack into the charger (Fig. 1). The red (charging) light will blink continu-

ously indicating that the charging process has started.

3. The completion of charge will be indicated by the red light remaining ON continuously. The

pack is fully charged and may be used at this time or left in the charger.

Indicator Light Operation

Charge Indicators

Some chargers are designed to detect certain problems that can arise with battery packs.

Problems are indicated by the red light flashing at a fast rate. If this occurs, re-insert battery pack

into the charger. If the problem persists, try a different battery pack to determine if the charger

is OK. If the new pack charges correctly, then the original pack is defective and should be

returned to a service center or other collection site for recycling. If the new battery pack elicits

the same trouble indication as the original, have the charger tested at an authorized service

center.

HOT/COLD PACK DELAY

Some chargers have a Hot/Cold Pack Delay feature: when the charger detects a battery that

is hot, it automatically starts a Hot Pack Delay, suspending charging until the battery has

cooled. After the battery has cooled, the charger automatically switches to the Pack Charging

mode. This feature ensures maximum battery life. The red light flashes long, then short while

in the Hot Pack Delay mode.

PROBLEM POWER LINE

Some chargers have a Problem Power Line indicator. When the charger is used with some

portable power sources such as generators or sources that convert DC to AC, the charger may

temporarily suspend operation,

flashing the red light with two fast blinks followed by a

pause

. This indicates the power source is out of limits.

LEAVING THE BATTERY PACK IN THE CHARGER

The charger and battery pack can be left connected with the red light glowing indefinitely. The

charger will keep the battery pack fresh and fully charged.

NOTE:

A battery pack will slowly lose its charge when kept out of the charger. If the battery

pack has not been kept on maintenance charge, it may need to be recharged before use. A

battery pack may also slowly lose its charge if left in a charger that is not plugged into an

appropriate AC source.

WEAK BATTERY PACKS:

Chargers can also detect a weak battery. Such batteries are still

usable but should not be expected to perform as much work. In such cases, about 10 seconds

after battery insertion, the charger will beep rapidly 8 times to indicate a weak battery condi-

tion. The charger will then go on to charge the battery to the highest capacity possible.

Important Charging Notes

1. Longest life and best performance can be obtained if the battery pack is charged when the

air temperature is between 65°F and 75°F (18°- 24°C). DO NOT charge the battery pack

in an air temperature below +40°F (+4.5°C), or above +105°F (+40.5°C). This is important

and will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch while charging. This is a nor-

mal condition, and does not indicate a problem.

3. If the battery pack does not charge properly:

a. Check current at receptacle by plugging in a lamp or other appliance

b. Check to see if receptacle is connected to a light switch which turns power off when you

turn out the lights.

c. Move charger and battery pack to a location where the surrounding air temperature is

approximately 65°F - 75°F (18°- 24°C).

d. If charging problems persist, take the tool, battery pack and charger to your local serv-

ice center.

4. The battery pack should be recharged when it fails to produce sufficient power on jobs

which were easily done previously. DO NOT CONTINUE to use under these conditions.

Follow the charging procedure. You may also charge a partially used pack whenever you

desire with no adverse affect on the battery pack.

5. Under certain conditions, with the charger plugged into the power supply, the exposed

charging contacts inside the charger can be shorted by foreign material. Foreign materials

of a conductive nature such as, but not limited to, steel wool, aluminum foil, or any buildup

of metallic particles should be kept away from charger cavities. Always unplug the charg-

er from the power supply when there is no battery pack in the cavity. Unplug charger before

attempting to clean.

6. Do not freeze or immerse charger in water or any other liquid.

WARNING:

Shock hazard. Do not allow any liquid to get inside charger.

CAUTION:

Never attempt to open the battery pack for any reason. If the plastic housing of

the battery pack breaks or cracks, return to a service center for recycling.

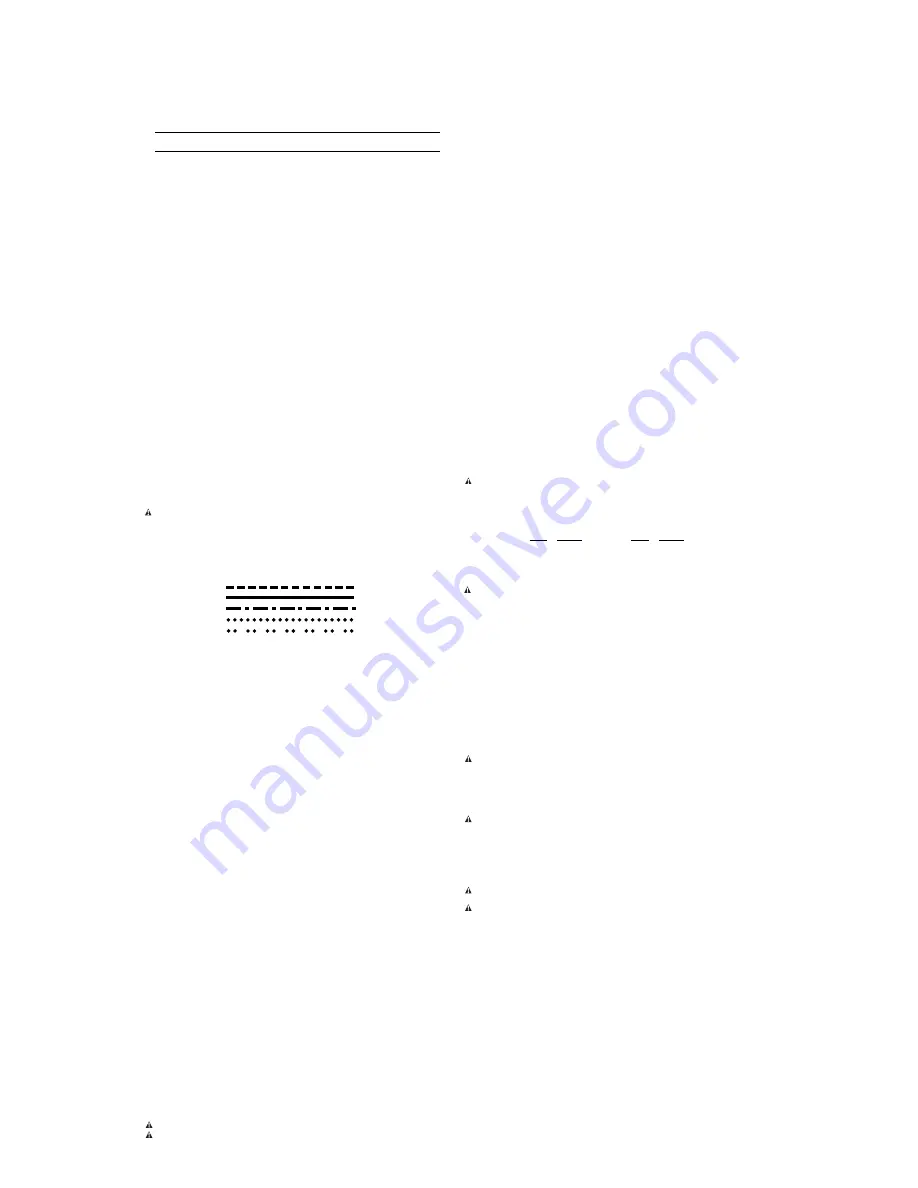

PACK CHARGING...................

FULLY CHARGED...................

HOT/COLD PACK DELAY........

REPLACE PACK......................

PROBLEM POWER LINE........

Motor

Voltage decrease of more than 10% will cause loss of power and overheating. All D

E

WALT

tools are factory tested; if this tool does not operate, check your battery pack.

Installing and Removing the Battery Pack

NOTE:

Make sure your battery pack is fully charged.

To install the battery pack into the tool handle

, align the base of the tool with the notch

inside the tool’s handle (Fig. 2) and slide the battery pack firmly into the handle until you hear

the lock snap into place (Fig. 3).

To remove the battery pack from the tool

, press the release buttons (A) and firmly pull

the battery pack out of the tool handle. Insert it into the charger as described in the charger

manual.

OPERATION

Switch - DW059 (Fig. 4)

Pressing the BOTTOM part of the rocker switch (B) runs the tool in forward (right hand thread)

direction. Pressing the TOP of the switch reverses motor direction. This allows “rocking”

fasteners to break them loose.

Variable Speed Trigger Switch (Fig. 4)

To turn the tool on, squeeze the trigger switch. To turn the tool off, release the trigger switch.

Your tool is equipped with a brake. The chuck will stop as soon as the trigger switch is fully

released. The variable speed switch enables you to select the best speed for a particular appli-

cation. The more you squeeze the trigger, the faster the tool will operate. Use lower speeds for

starting holes without a center punch, drilling in metals or plastics, or driving screws. For max-

imum tool life, use variable speed only for starting holes or fasteners.

NOTE:

Continuous use in variable speed range is not recommended. It may damage the

switch and should be avoided.

Forward/Reverse Control Button (Fig. 4)

A forward/reverse control button determines the direction of the tool and also serves as a lock

off button.

To select forward rotation,

release the trigger switch and depress the

forward/reverse control button on the right side of the tool.

To select reverse,

depress the for-

ward/reverse control button on the left side of the tool. The center position of the control button

locks the tool in the OFF position. When changing the position of the control button, be sure the

trigger is released.

NOTE:

The first time the tool is run after changing the direction of rotation, you may hear a

click on start up. This is normal and does not indicate a problem.

Quick Release Chuck – DW050, DW052, DW054, DW056

(Fig. 5)

NOTE:

The chuck accepts 1/4" (6.35 mm) hex accessories only.

Place the switch in the locked off (center) position or remove battery pack before changing

accessories.

To install an accessory

, pull the chuck collar away from the front of the tool, insert the acces-

sory, and release the collar. The accessory is locked in place.

To remove an accessory

, pull the chuck collar away from the front of the tool. Remove the

accessory and release the collar.

Anvil With Detent Pin – DW053, DW055, DW057, DW059

(Fig. 6)

Place the switch in the locked off (center) position or remove battery pack before changing

accessories.

To install a socket on the anvil,

align the hole in the side of the socket with the detent pin

(C) on the anvil (D). Press the socket on until the detent pin engages in the hole. Depression

of detent pin may be necessary to aid installation of socket.

CAUTION:

Use only impact sockets. Non-impact sockets may break and cause a haz-

ardous condition. Inspect sockets prior to use to ensure that it contains no cracks.

To remove a socket,

depress the detent pin through the hole, using a small pointed object,

and pull the socket off.

Usage

Your impact tool generates the following output torque:

Cat #

Ft.-Lbs.

Cat #

Ft.-Lbs.

DW050

75

DW055

129

DW051

100

DW056

98

DW052

83

DW057

138

DW053

117

DW059

300

DW054

96

CAUTION:

Ensure fastener and/or system will withstand the level of torque generated by

the tool. Excessive torque may cause breakage and possible personal injury.

1. Place the socket on the fastener head. Keep the tool pointed straight at the fastener.

2. Press rocker switch to start operation. Always check torque with a torque wrench, as the

fastening torque is affected by many factors including the following:

•

Voltage:

Low voltage, due to a nearly discharged battery, will reduce fastening torque.

•

Socket size:

Failure to use the correct socket size will cause a reduction in fastening

torque.

•

Bolt Size:

Larger bolt diameters generally require higher fastening torque. Fastening

torque will also vary according to length, grade, and torque coefficient.

•

Bolt:

Ensure that all threads are free of rust and other debris to allow proper fastening

torque

•

Material:

The type of material and surface finish of the material will affect fastening

torque.

•

Fastening Time:

Longer fastening time results in increased fastening torque. Using a

longer fastening time than recommended could cause the fasteners to be overstressed,

stripped or damaged.

MAINTENANCE

Cleaning

CAUTION:

Blow dirt and dust out of all air vents with dry air at least once a week. Wear safe-

ty glasses when performing this procedure. Never use solvents or other harsh chemicals for

cleaning the non-metallic parts of the tool. These chemicals may weaken the plastic materials

used in these parts. Use a cloth dampened only with water and mild soap. Do not use gaso-

line, turpentine, lacquer or paint thinner, dry cleaning fluids or similar products. Never let any

liquid get inside the tool; never immerse any part of the tool into a liquid.

CHARGER CLEANING INSTRUCTIONS

WARNING:

Disconnect the charger from the AC outlet before cleaning. Dirt and grease may

be removed from the exterior of the charger using a cloth or soft non-metallic brush. Do not

use water or any cleaning solutions.

Accessories

Recommended accessories for use with your tool are available at extra cost from your local

service center. If you need any assistance in locating any accessory, please contact D

E

WALT

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286, call 1-800-4-D

E

WALT (1-800-

433-9258) or visit our website www.dewalt.com.

CAUTION:

Use only impact sockets. Non-impact sockets may break and cause a

hazardous condition. Inspect sockets prior to use to ensure that it contains no cracks.

CAUTION:

The use of any other accessory not recommended for use with this tool could be

hazardous.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustments (includ-

ing brush inspection and replacement) should be performed by a D

E

WALT factory service cen-

ter, a D

E

WALT authorized service center or other qualified service personnel. Always use iden-

tical replacement parts.

Three Year Limited Warranty

D

E

WALT will repair, without charge, any defects due to faulty materials or workmanship for

three years from the date of purchase. This warranty does not cover part failure due to normal

wear or tool abuse. For further detail of warranty coverage and warranty repair information,

visit www.dewalt.com or call 1-800-4-D

E

WALT (1-800-433-9258). This warranty does not apply

to accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain

states or provinces.

In addition to the warranty, D

E

WALT tools are covered by our:

1 YEAR FREE SERVICE

D

E

WALT will maintain the tool and replace worn parts caused by normal use, for free, any time

during the first year after purchase.

2 YEARS FREE SERVICE ON

XRP™ BATTERY PACKS

DC9096, DC9091 and DC9071

If you are not completely satisfied with the performance of your D

E

WALT Power Tool, Laser,

or Nailer for any reason, you can return it within 90 days from the date of purchase with a

receipt for a full refund – no questions asked.

LATIN AMERICA:

This warranty does not apply to products sold in Latin America. For prod-

ucts sold in Latin America, see country specific warranty information contained either in the

packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT:

If your warning labels become illegible or are

missing, call 1-800-4-D

E

WALT for a free replacement.