12

English

S

S

EE

2. Use brush to remove carbon deposits from the spark arrester

screen. Inspect the spark arrester screen for holes or tears.

Replace the spark arrester if necessary.

WARNING:

Always wear certified safety equipment: ANSI Z87.1 eye

protection (CAN/CSA Z94.3) with side shields when removing carbon

deposits.

Drain Carburetor bowl (Fig. 1)

1. Place the fuel valve lever (J, if equipped) in the closed position.

2. Place an

OSHA-ap proved con tain er suitable for fuel under the

carburetor bowl (M).

notE:

Using a funnel will allow the fuel to flow

into the container with less spillage.

3. Remove the carburetor bowl drain (L).

4. Fuel will drain from carburetor bowl.

5. When drained, replace carburetor bowl drain.

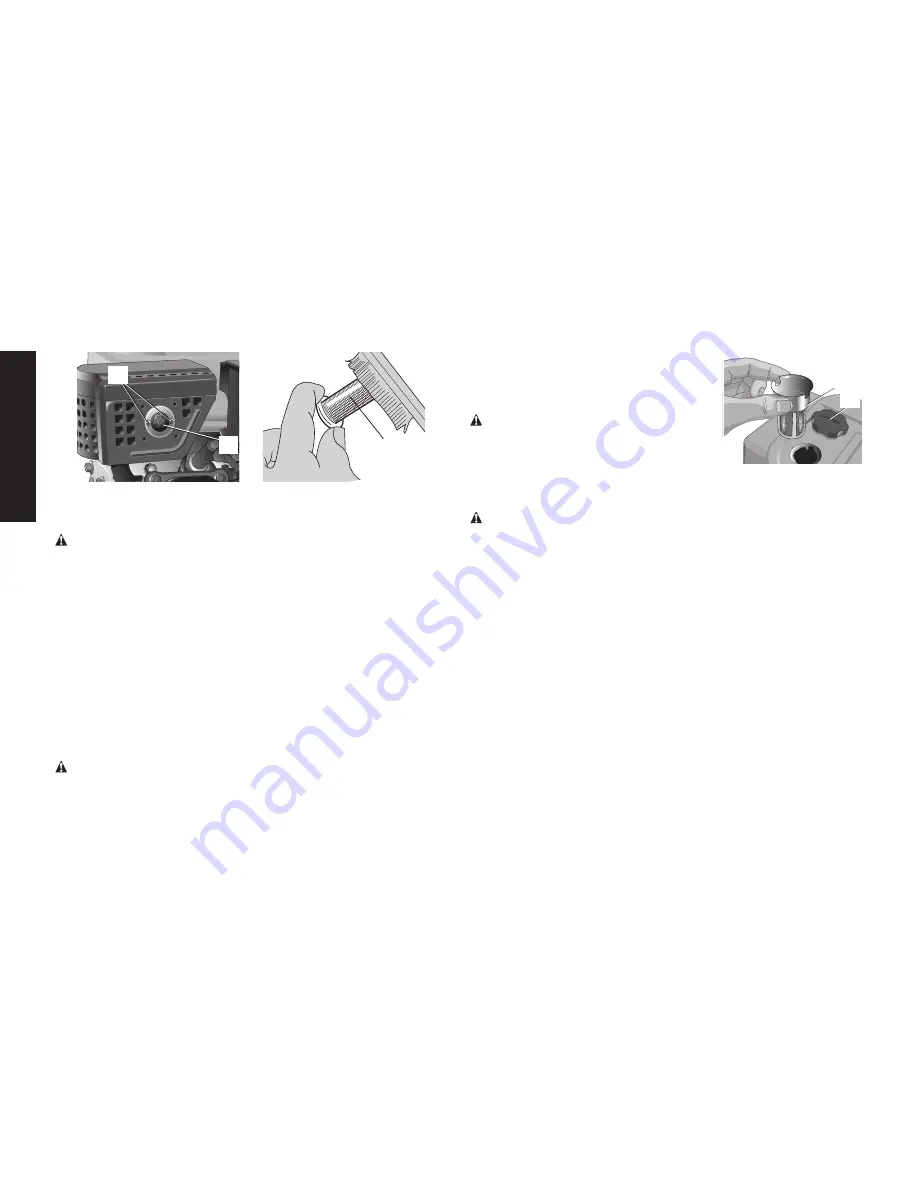

Cleaning Debris Screen (if equipped)

(Fig. 1)

WARNING:

Risk of explosion or fire. Gasoline vapor is highly flam-

mable. Refuel outdoors only in well-ventilated areas. Do not refuel or

check gasoline level while the engine is running. Do not store, spill, or

use gasoline near an open flame, a source of sparks (such as weld-

ing), or near operating electrical equipment.

1. Remove fuel cap (A).

2. Remove debris screen (P).

P

A

3. Clean debris screen. Use compressed

air to blow off debris.

WARNING

: When using compressed

air, user always must wear eye protec-

tion that conforms to ANSI Z87.1. (CAN/

CSA Z94.3).

4. Replace debris screen and fuel cap.

Storage

WARNING:

If the engine has been running, the muffler will be

very hot. To reduce the risk of injury, allow engine to cool before

proceeding.

If storing the unit for more than thirty days drain all fuel out of fuel

lines, tank and carburetor bowl. Drain oil and refill with fresh, clean

oil.

IMportAnt:

Fuel will oxidize and deteriorate in storage. If fuel

is allowed to deteriorate during storage the carburetor and fuel

related parts will need to be serviced.

notE:

Fuel stabilizer can

be used to lengthen the fuel life, follow the fuel stabilizer’s recom-

mended instructions.

repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement)

should be performed by authorized service centers or other qualified

service personnel, always using identical replacement parts.

Summary of Contents for DW13LAG

Page 47: ......