19

E N G L I S H

en - 5

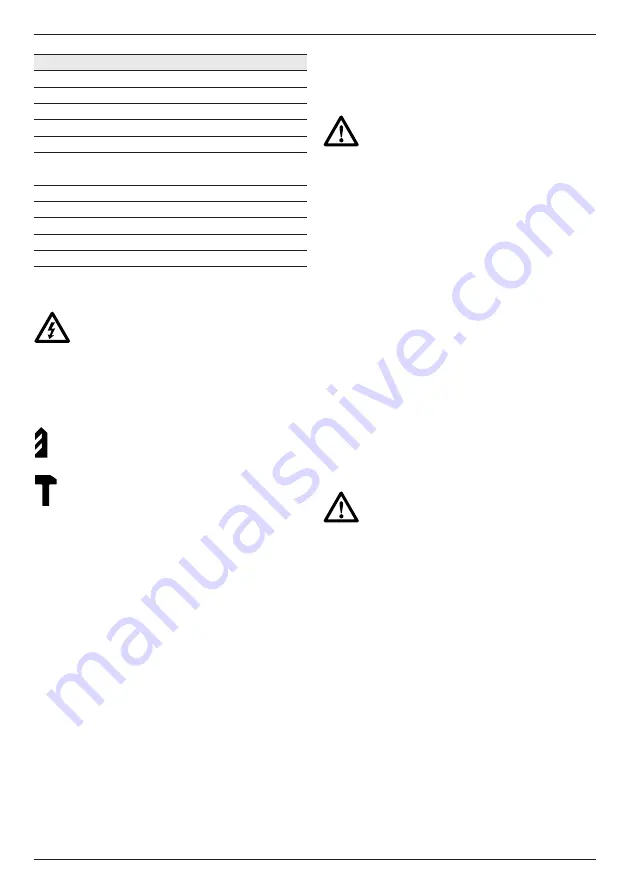

Voltage

Amperes

Cable rating (Amperes)

115

0 - 2.0

6

6

6

6

6

10

2.1 - 3.4

6

6

6

6

15

15

3.5 - 5.0

6

6

10

15

20

20

5.1 - 7.0

10

10

15

20

20

25

7.1 - 12.0

15

15

20

25

25

-

220/240

0 - 2.0

6

6

6

6

6

6

2.1 - 3.4

6

6

6

6

6

6

3.5 - 5.0

6

6

6

6

10

15

5.1 - 7.0

10

10

10

10

15

15

7.1 - 12.0

15

15

15

15

20

20

12.1 - 20.0

20

20

20

20

25

-

Assembly and adjustment

Prior to assembly and adjustment always

unplug the tool.

Selecting the operating mode (fig. B)

The percussion drills can be used in two operating

modes:

Rotary drilling:

for steel, wood and plastics.

Percussion drilling:

simultaneous rotating and impacting for

concrete and masonry drilling operations.

• Select the required operating mode by rotating

the symbol on the mode selector (5) towards the

respective symbol on the gear housing.

Inserting and removing a bit (fig. A)

Keyed chuck

• Open the chuck by turning the sleeve (9)

counterclockwise and insert the bit shank.

• Put the chuck key (10) into each hole in the side

of the chuck and turn clockwise until tight.

Keyless chuck

• Open the chuck by turning the sleeve

counterclockwise and insert the bit shank.

• Tighten firmly by turning the sleeve clockwise.

• To remove the bit, proceed in reverse order.

Fitting the side handle (fig. A)

The side handle (6) can be fitted to suit both

RH- and LH-users.

Always use the Drill with the side handle

properly assembled.

• Loosen the side handle.

• For RH-users, slide the side handle clamp over the

43 mm collar behind the chuck, handle at the left.

• For LH-users, slide the side handle clamp over the

43 mm collar behind the chuck, handle at the right.

• Rotate the side handle to the desired position

and tighten the handle.

Setting the drilling depth (fig. C)

• Insert the required drill bit into the chuck.

• Slacken the side handle (6).

• Fit the depth adjustment rod (7) through the hole

in the side handle clamp.

• Adjust the drilling depth as shown.

• Tighten the side handle.

Forward/reverse slider (fig. D)

• To select forward or reverse rotation, use the

forward/reverse-switch (3) (see arrow on tool).

Always wait until the motor has come to

a complete standstill before changing the

direction of rotation.

Two gear selector (fig. E)

Your tool is fitted with a two gear selector to vary the

speed/torque ratio.

• Release the variable speed switch and select the

required position. This can be done either with

the tool switched OFF or running under no load

condition. Always align the selector with the

arrow on the gear housing:

1 low speed/high torque

(drilling large holes, driving large screws)

2 high speed/low torque

(drilling smaller holes, drilling in wood)

For speed rates, refer to the technical data.

• Do not change gears at full speed or during use.

Summary of Contents for DW513

Page 1: ...86 DW513 DW513K DW515 DW515K ...

Page 3: ...88 ...

Page 4: ...89 A 10 8 8 7 9 1 2 6 4 3 5 ...

Page 5: ...90 B C 5 6 7 ...

Page 6: ...91 D F 3 8 11 10 E ...

Page 7: ...92 11 G ...

Page 89: ...82 ...

Page 90: ...83 ...

Page 91: ...84 ...