7

English

FIG. 9

NOTE:

Certain special cuts of large material will require that

you manually raise the guard. See page 12.

The front section of the guard is louvered for visibility

while cutting. Although the louvers dramatically reduce fly-

ing debris, they are openings in the guard and safety

glasses should be worn at all times when viewing through

the louvers.

Brushes

DISCONNECT PLUG FROM POWER SUPPLY

Inspect carbon brushes regularly by unplugging tool, remov-

ing the motor end cap (Figure 2), lift the brush spring and

withdraw the brush assembly. Keep brushes clean and slid-

ing freely in their guides. Always replace a used brush in the

same orientation in the holder as it was prior to its removal.

Carbon brushes have varying symbols stamped into their

sides, and if the brush is worn down to approximately 1/2

inch, the spring will no longer exert pressure and they must

be replaced. Use only identical D

E

WALT brushes. Use of

the correct grade of brush is essential for proper operation

of electric brake. New brush assemblies are available at

D

E

WALT service centers. The tool should be allowed to “run

in” (run at no load) for 10 minutes before use to seat new

brushes. The electric brake may be erratic in operation until

the brushes are properly seated (worn in). Always replace

the brush inspection cap after inspection or servicing the

brushes.

While “running in” DO NOT TIE, TAPE, OR OTHERWISE

LOCK THE TRIGGER SWITCH ON. HOLD BY HAND

ONLY.

Controls

Your compound miter saw has several main controls, which

will be discussed briefly here. For more information on these

controls, see the respective sections later in the manual.

MITER CONTROL (FIG. 7)

The miter lock/adjustment lever and trigger allows you to

miter your saw 50˚ left and right. To miter the saw, loosen

the miter lock handle (A) by rotating it counterclockwise,

squeeze the detent trigger (B) and set the miter angle

desired on the miter scale. Tighten the miter lock handle by

rotating it clockwise.

TRIGGER SWITCH

The trigger switch (Fig. 2) turns your saw on and off. A hole

is provided in the trigger for insertion of a padlock to secure

the saw.

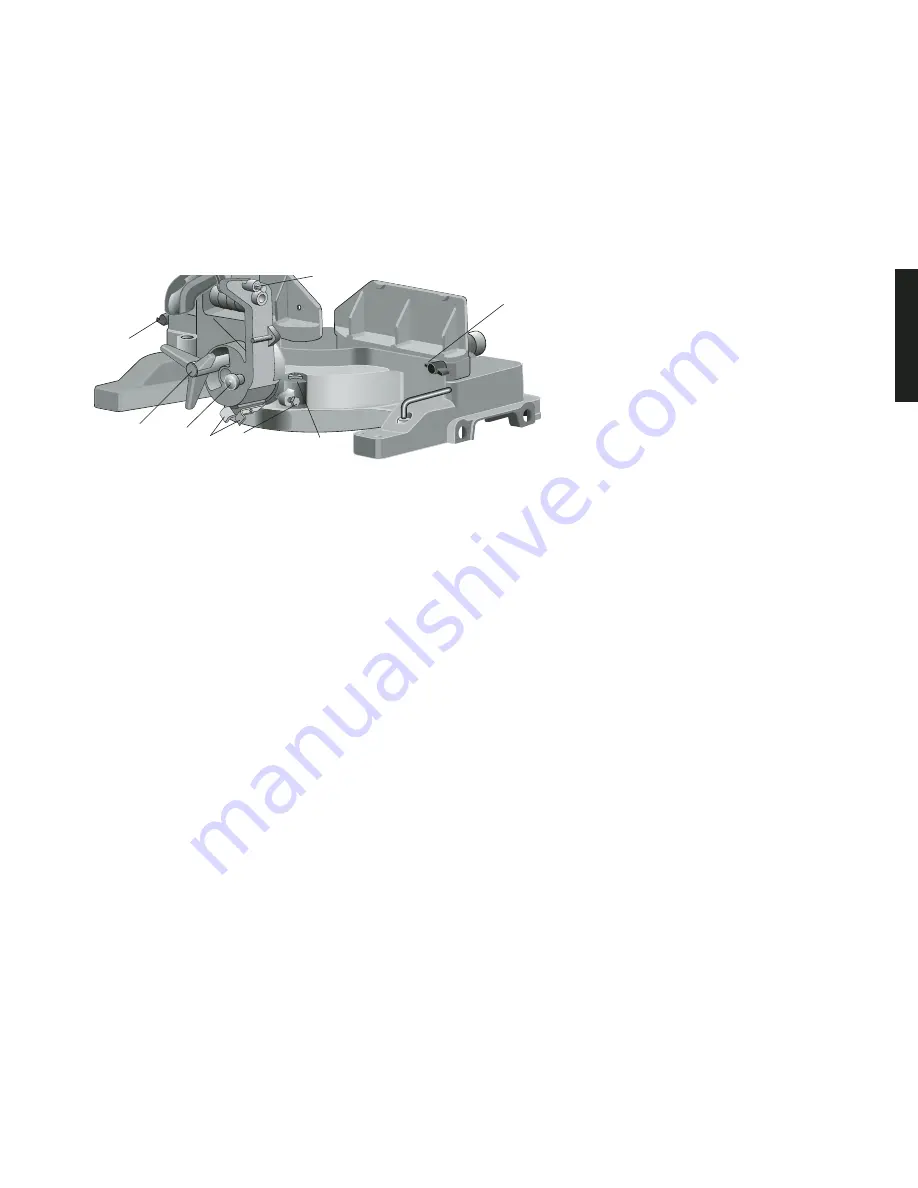

BEVEL LOCK (FIG. 9)

The bevel lock handle (A) allows you to bevel the saw 48˚

left or right. To loosen the handle and adjust the bevel set-

ting, turn the handle counterclockwise, the saw head bevels

easily to the left or to the right once the 0˚ bevel override

knob (B) is pulled. To tighten, turn the handle clockwise.

Bevel degree markings are on the bottom front of the saw

arm. (C-Fig. 7)

0˚ BEVEL OVERRIDE (FIG. 9)

The bevel stop override (B) allows you to bevel the saw to

the right past the 0˚ mark.

The saw will automatically stop at 0˚ when brought up from

the left. To move past 0˚ to the right, pull the bevel stop

knob. The stop knob can be locked out by pulling the knob

out and rotating it 180˚.

45˚ BEVEL STOP OVERRIDES (FIG. 9)

The bevel stop overrides are held secure with their attach-

ment screw to prevent inadvertent movement. Use the bit on

the blade wrench to loosen the attachment screw. This

allows the slides, (G) to be pulled outward and the saw head

to pivot past the 45˚ mark. Be sure to retighten the attach-

ment screw when finished.

A

B

C

C

D

E

F

33.85˚ BEVEL STOPS (FIG. 9)

The two pawls (D) are used to stop the saw head bevel set-

ting at 33.85˚. This setting is used primarily for cutting crown

moldings laid flat on the table.

HEAD DOWNLOCK PIN (FIG. 9)

To lock the saw head in the down position, push the head

down, push the pin (E) in and release the saw head. This

will hold the saw head safely down for moving the saw from

place to place. To release, press the saw head down and

pull the pin out.

Operation

Plug the saw into any household 60 Hz power source. Refer

to the nameplate for voltage. Be sure the cord will not inter-

fere with your work.

SWITCH

To turn the saw on, depress the trigger switch. To turn the

tool off, release the switch. Allow the blade to spin up to full

operating rpm before making the cut. Release the trigger

switch and allow the brake to stop the blade before raising

the saw head. There is no provision for locking the switch

on, but a hole is provided in the trigger for insertion of a pad-

lock to lock the saw off.

CUTTING WITH YOUR SAW

NOTE:

Although this saw will cut wood and many non-fer-

rous materials, we will limit our discussion to the cutting of

wood only. The same guidelines apply to the other materi-

als.

DO NOT CUT FERROUS (IRON AND STEEL) MATE-

RIALS OR MASONRY WITH THIS SAW.

Do not use any

abrasive blades.

CROSSCUTS

Cutting of multiple pieces is not recommended but can be

done safely by ensuring that each piece is held firmly

against the table and fence. A crosscut is made by cutting

wood across the grain at any angle. A straight crosscut is

made with the miter arm at the zero degree position. Set the

miter arm at zero, hold the wood on the table and firmly

against the fence. Turn on the saw by squeezing the trigger.

When the saw comes up to speed (about 1 second) lower

the arm smoothly and slowly to cut through the wood. Let the

blade come to a full stop before raising arm.

Miter crosscuts are made with the miter arm at some angle

other than zero. This angle is often 45 degrees for making

corners, but can be set anywhere from zero to 50 degrees

left or right. After selecting the desired miter angle, be sure

to tighten the miter clamp knob. Make the cut as described

above.

BEVEL CUTS

A bevel cut is a crosscut made with the saw blade at a bevel

to the wood. In order to set the bevel, loosen the bevel

clamp knob and move the saw to the left as desired. (It is

necessary to move the fence to allow clearance). Once the

G