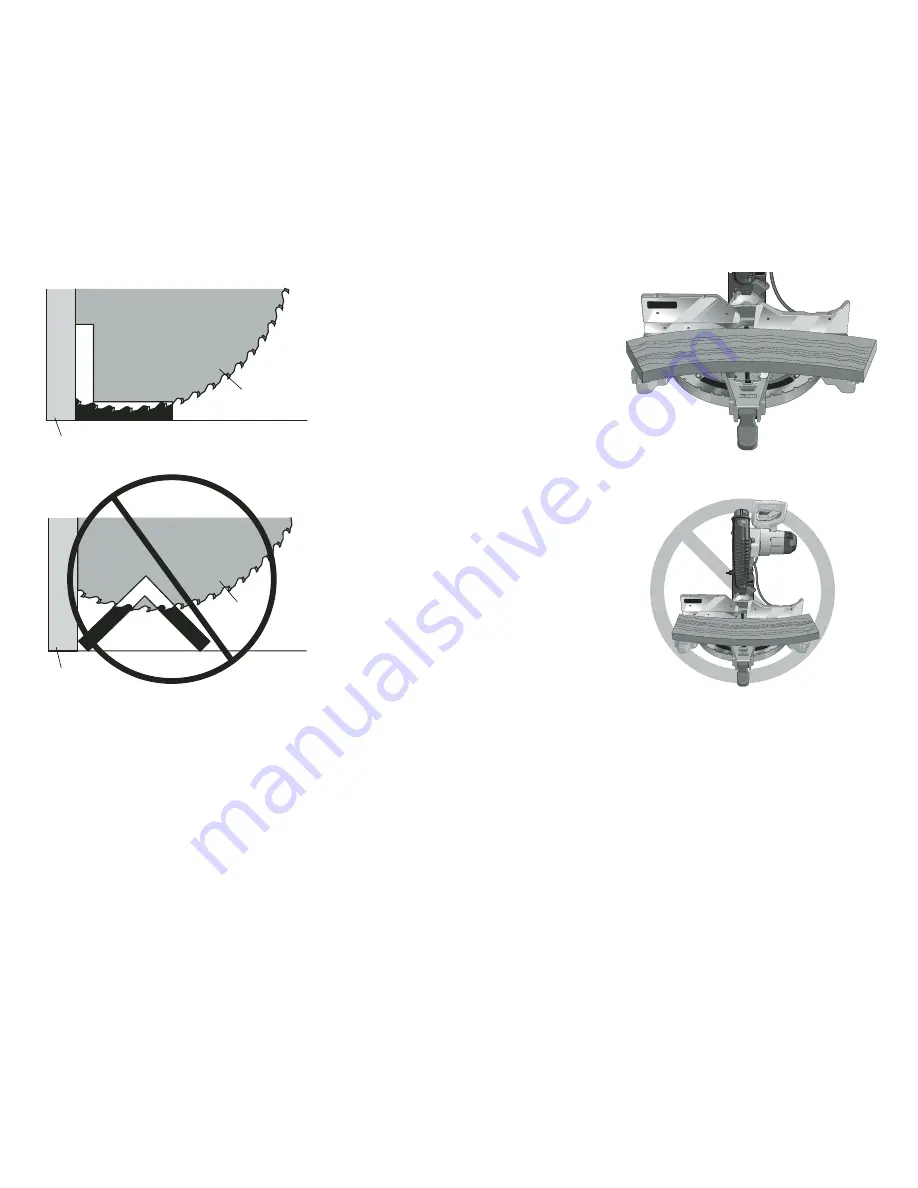

FIG. 21

FIG. 21A

RIGHT

WRONG

12

Special Cuts

NEVER MAKE ANY CUT UNLESS THE MATERIAL IS SECURED ON THE

TABLE AND AGAINST THE FENCE.

ALUMINUM CUTTING

ALWAYS USE THE APPROPRIATE SAW BLADE MADE ESPECIALLY FOR

CUTTING ALUMINUM. Certain workpieces, due to their size, shape or

surface finish, may require the use of a clamp or fixture to prevent

movement during the cut. Position the material so that you will be cutting

the thinnest cross section, as shown in Figure 20. Figure 20A illustrates

the wrong way to cut these extrusions. Use a stick wax cutting lubricant

when cutting aluminum. Apply the stick wax directly to the saw blade

before cutting. Never apply stick wax to a moving blade.

The wax, available at most hardware stores and industrial mill supply

houses, provides proper lubrication and keeps chips from adhering to the

blade.

Be sure to properly secure workpiece. Refer to page 3 for correct saw

blade.

FIG. 20

BLADE

FENCE

RIGHT

FIG. 20A

BLADE

FENCE

WRONG

Normal wear parts are not covered in this service. Carbon brushes worn

more then 50% will be replaced.

NOTE:

Three Year Warranty is not applicable to items deemed as con-

sumables. Radial arm saws are covered by a one (1) year warranty only.

D

E

WALT Reserves the right to review its warranty policy |prior to launch

of any new business

development products.

30 DAY NO SATISFACTION GUARANTEE

If you are dissatisfied with any D

E

WALT power tool, laser or nailer, for any

reason, simply return it to

the point of purchase with your sales receipt within 30 days for a replace-

ment unit or a full refund.

FREE WARNING LABEL REPLACEMENT:

If your warning labels become

illegible or are missing, call (AUS) 1800 654 155 or (NZ) 09 526 2556

for a free replacement.

BOWED MATERIAL

When cutting bowed material always position it as shown in Figure 21

and never like that shown in Figure 21A. Positioning the material incor-

rectly will cause it to pinch the blade near the completion of the cut.

CUTTING PLASTIC PIPE OR OTHER ROUND MATERIAL

Plastic pipe can be easily cut with your saw. It should be cut just like

wood and

CLAMPED OR HELD FIRMLY TO THE FENCE TO KEEP IT

FROM ROLLING

. This is extremely important when making angle cuts.

CUTTING LARGE MATERIAL

Occasionally you will encounter a piece of wood a little too large to fit

beneath the blade guard. If this occurs, simply place your right thumb on

the upper side of the guard and roll the guard up just enough to clear the

workpiece, as shown in Figure 16. Avoid doing this as much as possible,

but if need be, the saw will operate properly and make the bigger cut.

NEVER TIE, TAPE, OR OTHERWISE HOLD THE GUARD OPEN WHEN

OPERATING THIS SAW.

Maintenance

1. All bearings are sealed. They are lubricated for life and need no

further maintenance.

2. Periodically clean all dust and wood chips from around AND UNDER

the base and the rotary table. Even though slots are provided to allow

debris to pass through, some dust will accumulate.

3. The brushes are designed to give you several years of use. If they

ever need replacement follow the instructions on page 7 or return the

tool to the nearest service center for repair. Service center locations

are packed with your tool.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustments should be performed by a D

E

WALT factory service center, a

D

E

WALT authorized service center or other qualified service personnel.

Always use identical replacement parts.

Guarantee

Applicable to hand held Power Tools, Lasers and Nailers.

Three Year Limited Warranty

D

E

WALT will repair, without charge, any defects due to faulty materials or

workmanship for three years from the date of purchase. Please return the

complete unit, transportation prepaid, to any D

E

WALT Service Centre, or

any authorised service station.

For warranty repair information, call (AUS) 1800 654 155 or (NZ) 09 526

2556.

This warranty does not apply to

• Accessories

• Damage caused where repairs have been made or attempted by

others.

• Damage due to misuse, neglect, wear and tear, alteration or

modification.

This warranty gives you specific legal rights and you may have other rights

under the provisions of the Consumer Guarantee Act 1993 (New Zealand

only), Trade Practices Act 1974 and State Legislation (Australia only).

In addition to the warranty, D

E

WALT tools are covered by our:

FREE ONE YEAR SERVICE CONTRACT

D

E

WALT will also maintain the tool for free at any time during the first

year of purchase. This includes labour, parts and lubrication required to

restore the product to sound mechanical and/or electrical condition.