3

WARNING:

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated timber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals: work in a well ventilated area, and work with approved safety equipment, such

as those dust masks that are specially designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction

activities. Wear protective clothing and wash exposed areas with soap and water.

Allowing dust to get

into your mouth, eyes, or lay on the skin may promote absorption of harmful chemicals.

WARNING:

Use of this tool can generate and/or disburse dust, which may cause serious and permanent

respiratory or other injury. Always use NIOSH/OSHA approved respiratory protection appropriate for the dust

exposure. Direct particles away from face and body.

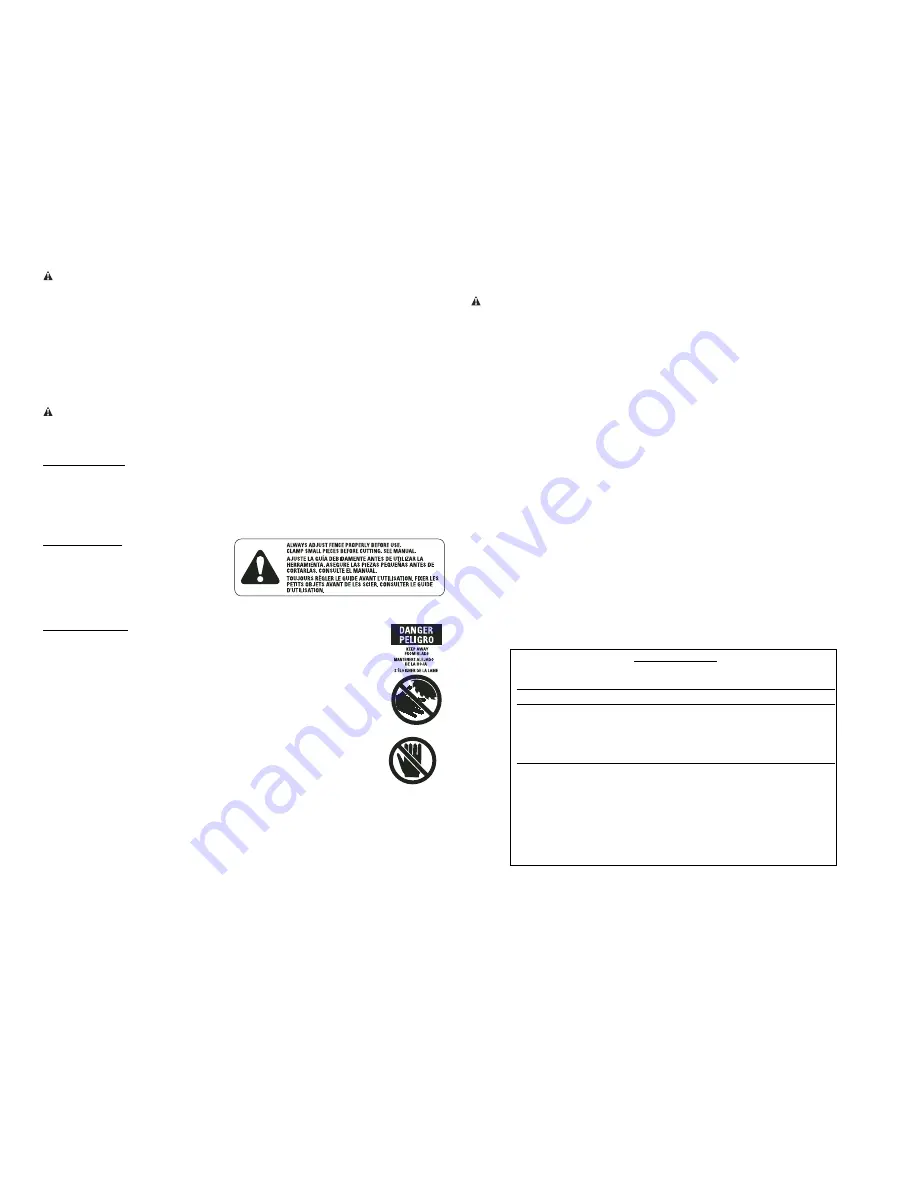

For your convenience and safety, the following warning labels are on your miter saw.

ON MOTOR HOUSING:

WARNING: FOR YOUR OWN SAFETY, READ INSTRUCTION MANUAL BEFORE OPERATING SAW.

WHEN SERVICING, USE ONLY IDENTICAL REPLACEMENT PARTS.

DO NOT EXPOSE TO RAIN OR USE IN DAMP LOCATIONS.

ALWAYS WEAR EYE PROTECTION.

ON MOVING FENCES:

ALWAYS ADJUST FENCE PROPERLY BEFORE USE.

Clamp small pieces before cutting. See manual.

ON GUARD: DANGER – KEEP AWAY FROM BLADE.

ON UPPER GUARD: PROPERLY SECURE BRACKET

WITH BOTH SCREWS BEFORE USE.

ON TABLE: (2 PLACES)

ALWAYS TIGHTEN ADJUSTMENT KNOBS BEFORE USE.

KEEP HANDS 150MM (6") FROM PATH OF SAW BLADE.

NEVER PERFORM ANY OPERATION FREEHAND.

NEVER CROSS ARMS IN FRONT OF BLADE.

THINK! YOU CAN PREVENT ACCIDENTS.

DO NOT OPERATE SAW WITHOUT GUARDS IN PLACE.

TURN OFF TOOL, KEEP SAW HEAD DOWN AND WAIT FOR SAW TO

STOP BEFORE MOVING HANDS, WORKPIECE OR CHANGING SETTINGS.

UNPLUG TOOL BEFORE CHANGING BLADE, MOVING OR SERVICING UNIT.

Electrical Safety

The electric motor has been designed for one voltage only. Always check that the power supply corresponds to

the voltage on the rating plate. 230 V AC means your tool will operate on alternating current. As little as 10%

lower voltage can cause loss of power and can result in overheating. All D

E

WALT tools are factory tested; if this

tool does not operate, check the power supply. Your D

E

WALT tool is double insulated, therefore no earth wire is

required.

•

Young children and the infirm.

This appliance is not intended for use by young children or infirm persons

without supervision. Young children should be supervised to ensure that they do not play with this appliance.

•

Replacement of the supply cord.

If the supply cord is damaged, it must be replaced by the manufacturer or

an authorised D

E

WALT Service Centre in order to avoid a hazard.

Accessories

Recommended accessories for use with your tool are available at extra cost from your local service center.

CAUTION:

The use of any non-recommended accessory may be hazardous. Dado sets, molding cutters or

abrasive wheels should not be used on your miter saw.

If you need any assistance in locating any accessory, please contact: D

E

WALT Industrial Tool Co., 20 Fletcher

Road, Mooroolbark, VIC 3138 Australia, call 1800 654 155 or 21 Hugo Johnston Drive, Penrose, Auckland, New

Zealand, call 09 5797600.

Optional Accessories

The following accessories, designed for your saw, may be helpful. In some cases, other locally obtained work

supports, length stops, clamps, etc., may be more appropriate. Use care in selecting and using accessories.

Laser Guide System: DW7187

Laser is available at extra cost from D

E

WALT Service Centers and your home improvement retailer.

Instructions for installation are included with the accessory. Read and follow all directions for safe

installation and use.

Extension, Work Support: DW7080 (page 4)

Used to support long overhanging workpieces, the work support is user assembled. Your saw table is

designed to accept two work supports; one on each side.

Adjustable Length Stop: DW7051 (page 4)

Requires the use of one work support (see drawing). It is used to make repetitive cuts of the same length

from 0 to 1067mm (0 to 42").

Clamp: DW7082 (similar model included)

Used for firmly clamping workpiece to the saw table for precision cutting.

Dust Bag: DW7053 (Included with some models)

Equipped with a zipper for easy emptying, the dust bag will capture the majority of the sawdust produced

(not shown).

NOTE:

Deflector on dust spout channels debris to ground. Spout has a provision to attach a vacuum hose to

collect sawdust. Lift dust spout to connect hose.

Crown Molding Fence: DW7084 (Not available in Australia or New Zealand)

Used for precision cutting of crown molding.

SAW BLADES: ALWAYS USE 305mm (12") SAW BLADES WITH 25.4mm (1") ARBOR HOLES. SPEED RATING

MUST BE AT LEAST 4800 RPM. Never use a smaller diameter blade. It will not be guarded properly.

* Currently not available in Australia or New Zealand

BLADE DESCRIPTIONS

TOOTH

APPLICATION

MODEL #

TEETH

GRIND

Construction Saw Blades

(thin kerf with anti-stick rim)

General Purpose

DW3123

32

ATB

Fine Crosscuts

DW3126

60

ATB

Fine Crosscuts

DW3128

80

ATB

Woodworking Saw Blades

(provide smooth, clean cuts)

Fine crosscuts

DW7648

60

ATB

*Fine crosscuts

DW7649

80

ATB

*Ultra-fine crosscuts

DW7650

96

ATB

*Laminates

DW7661

80

TCG

*Solid surface

and plastics

DW7668

80

Mod TCG

*Non-ferrous metals

DW7666

80

TCG