6

LOW SPEED/HIGH

TORQUE

0-450 rpm (position 1)

HIGH SPEED/LOW

TORQUE

0-1400 rpm (position 2)

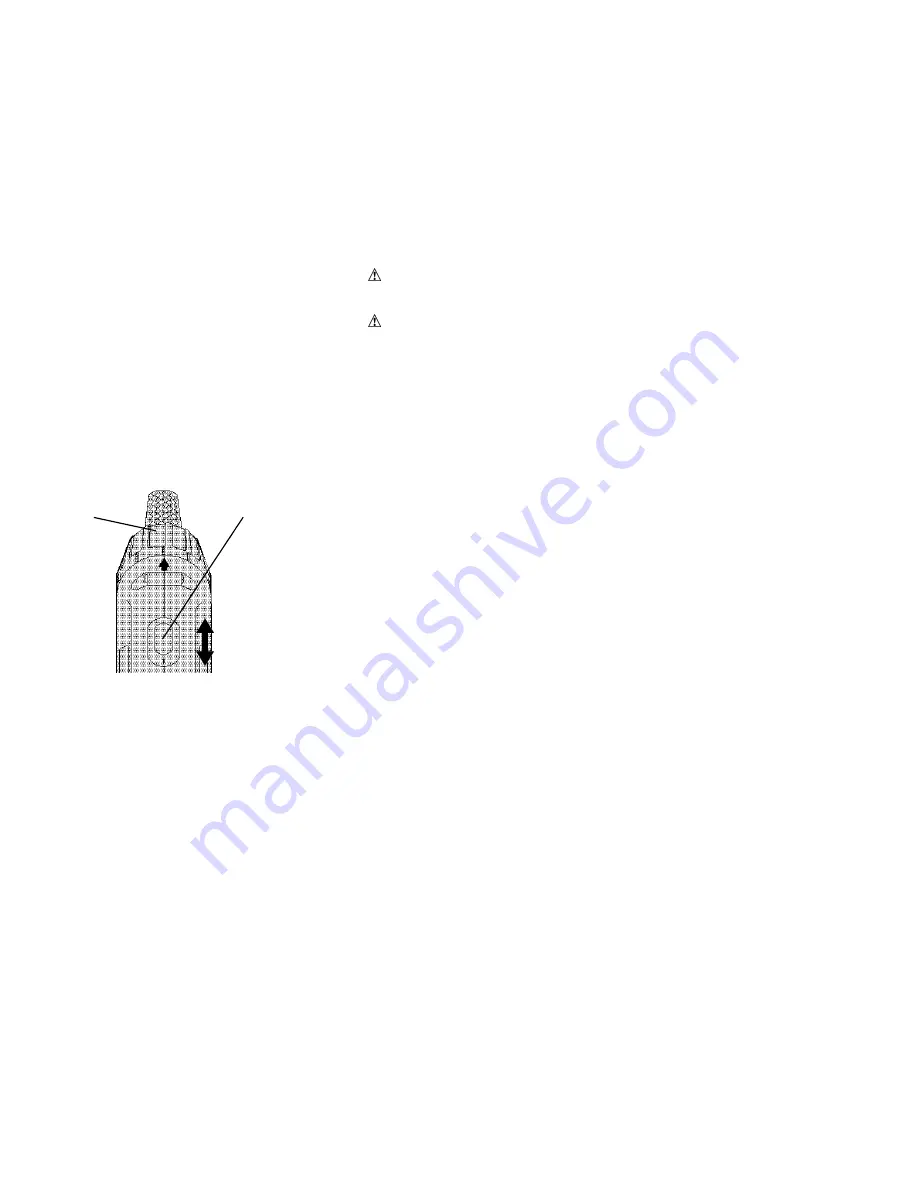

DUAL RANGE

GEAR SHIFTER

FIG. 5

TORQUE

ADJUSTMENT

COLLAR

is important and will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to touch while

charging. This is a normal condition, and does not indicate a prob-

lem.

3. If the battery pack does not charge properly — (1) Check current

at receptacle by plugging in a lamp or other appliance, (2) Check

to see if receptacle is connected to a light switch which turns

power off when you turn out the lights. (3) Move charger and bat-

tery pack to a location where the surrounding air temperature is

approximately 65°F - 75°F (18°- 24°C). (4) If charging problems

persist, take or send the tool, battery pack and charger to your

local service center.

4. The battery pack should be recharged when it fails to produce suf-

ficient power on jobs which were easily done previously. DO NOT

CONTINUE to use under these conditions. Follow the charging

procedure. You may also charge a partially used pack whenever

you desire with no adverse affect on the battery pack.

6. Do not immerse charger in water or any other liquid.

WARNING: Don't allow any liquid to get inside charger. Electric

shock may result. To facilitate the cooling of the battery pack after

use, avoid placing the charger or battery pack in a warm

environment such as in a metal shed, or an uninsulated trailer.

CAUTION: Never attempt to open the battery pack for any

reason. If the plastic housing of the battery pack breaks or

cracks, return to a service center for recycling.

Operation

Forward/Reverse Control Button

A forward/reverse control button determines the direction of the

tool and also serves as a “lock off” button. To select forward

rotation, release the trigger switch and depress the

forward/reverse control button on the right side of the tool, as

shown in Figure 4.

To select reverse, depress the forward/reverse control button on

the left side of the tool as shown in Figure 4. The center position of

the control button locks the tool in the “OFF” position as shown in

Figure 4.

When changing the position of the forward/reverse control button,

be sure the trigger is released.

NOTE: The first time the tool is run after changing the direction of

rotation, you may hear a click on start up. This is normal and does

not indicate a problem. See Fig. 4.

Torque Adjustment Collar

Your driver/drill has an adjustable torque screwdriver mechanism

for driving and removing a wide array of fastener shapes and

sizes.

Circling the collar are numbers ranging from 0 to 5, and a drill bit

symbol. These numbers (and half numbers designated by dots on

the collar) are used to designate a torque range set within the tool.

The higher the number on the collar, the higher the torque and the

Summary of Contents for DW970

Page 1: ......