flow of dust indicates the proper drilling rate.

Operation as a Screwdriver

Turn the Driver/Drill selector to the symbol of a screw. Select the desired

speed/torque range using the dual range gear shifter on the top of tool to

match the speed and torque to the planned operation. Insert the desired

fastener accessory into the chuck as you would any drill bit. Make a few

practice runs in scrap or unseen areas to determine the proper position of

the clutch collar.

Pressure Activated Chuck

When in the screwdriving mode, THE CHUCK WILL NOT TURN

UNTIL PRESSURE IS APPLIED IN LINE WITH THE FASTENER.

Likewise, the chuck stops when pressure is released. This pressure

activated chuck feature improves accuracy of work and significantly

increases the rate at which screws can be driven.

Maintenance

CLEANING: With the motor running, blow dirt and dust out of all air

vents with dry air at least once a week. Wear safety glasses when

performing this. Exterior plastic parts may be cleaned with a damp

cloth and mild detergent. Although these parts are highly solvent

resistant, NEVER use solvents.

Charger Cleaning Instructions:

WARNING: Disconnect the charger from the AC outlet before

cleaning.

Dirt and grease may be removed from the exterior of the charger

using a cloth or soft non-metallic brush. Do not use water or any

cleaning solutions.

Accessories

Recommended accessories for use with your tool are available at

extra cost from your local service center.

CAUTION: The use of any non-recommended accessory may be

hazardous.

8

English

block, etc., use carbide-tipped bits.

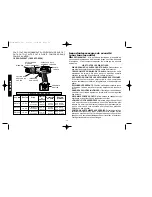

2. Be sure the material to be drilled is anchored or clamped firmly. If

drilling thin material, use a “back-up” block to prevent damage to the

material.

3. Always apply pressure in a straight line with the bit. Use enough

pressure to keep the drill bit biting, but do not push hard enough to

stall the motor or deflect the bit.

4. Hold tool firmly to control the twisting action of the drill.

5. IF DRILL STALLS, it is usually because it is being overloaded.

RELEASE TRIGGER IMMEDIATELY, remove drill bit from work, and

determine cause of stalling. DO NOT CLICK TRIGGER OFF AND ON

IN AN ATTEMPT TO START A STALLED DRILL – THIS CAN

DAMAGE THE DRILL.

6. To minimize stalling or breaking through the material, reduce pressure

on drill and ease the bit through the last fractional part of the hole.

7. Keep the motor running when pulling the bit back out of a drilled hole.

This will help prevent jamming.

8. With variable speed drills there is no need to center punch the point to

be drilled. Use a slow speed to start the hole and accelerate by

squeezing the trigger harder when the hole is deep enough to drill

without the bit skipping out. Operate at full on after starting the bit.

Drilling in Wood

Holes in wood can be made with the same twist drills used for metal.

These bits may overheat unless pulled out frequently to clear chips from

the flutes. For larger holes, use low speed wood bits. Work that is likely to

splinter should be backed up with a block of wood.

Drilling in Metals

Use a cutting lubricant when drilling metals. The exceptions are cast iron

and brass which should be drilled dry. The cutting lubricants that work best

are sulphurized cutting oil or lard oil; bacon grease will also serve the

purpose.

Drilling Masonry

Use carbide tipped masonry bits at low speeds. Keep even force on the

drill but not so much that you crack the brittle materials. A smooth, even

385360/DW974 etc 5/2/02 11:25 AM Page 8