Variable Speed Switch

To turn the tool on, squeeze the trigger switch. To turn the tool off,

release the trigger switch. Your tool is equipped with a brake. The

chuck will stop as soon as the trigger switch is fully released.

The variable speed switch enables you to select the best speed for

a particular application. The farther you squeeze the trigger, the

faster the tool will operate. Use lower speeds for starting holes

without a centerpunch, drilling in metals or plastics, driving screws

and drilling ceramics, or in any application requiring high torque.

Higher speeds are better for drilling in wood, wood compositions

and for using abrasive and polishing accessories. For maximum tool

life, use variable speed only for starting holes or fasteners.

NOTE: Continuous use in variable speed range is not recommended.

It may damage the switch and should be avoided.

Forward/Reverse Control Button

(FIG. 4) A forward/reverse control button determines the direction of

the tool and also serves as a lock off button. To select forward

rotation, release the trigger switch and depress the forward/reverse

control button on the right side of the tool.To select reverse, depress

the forward/reverse control button on the left side of the tool. The

center position of the control button locks the tool in the off position.

When changing the position of the control button, be sure the trigger

is released. NOTE: The first time the tool is run after changing the

direction of rotation, you may hear a click on start up. This is normal

and does not indicate a problem.

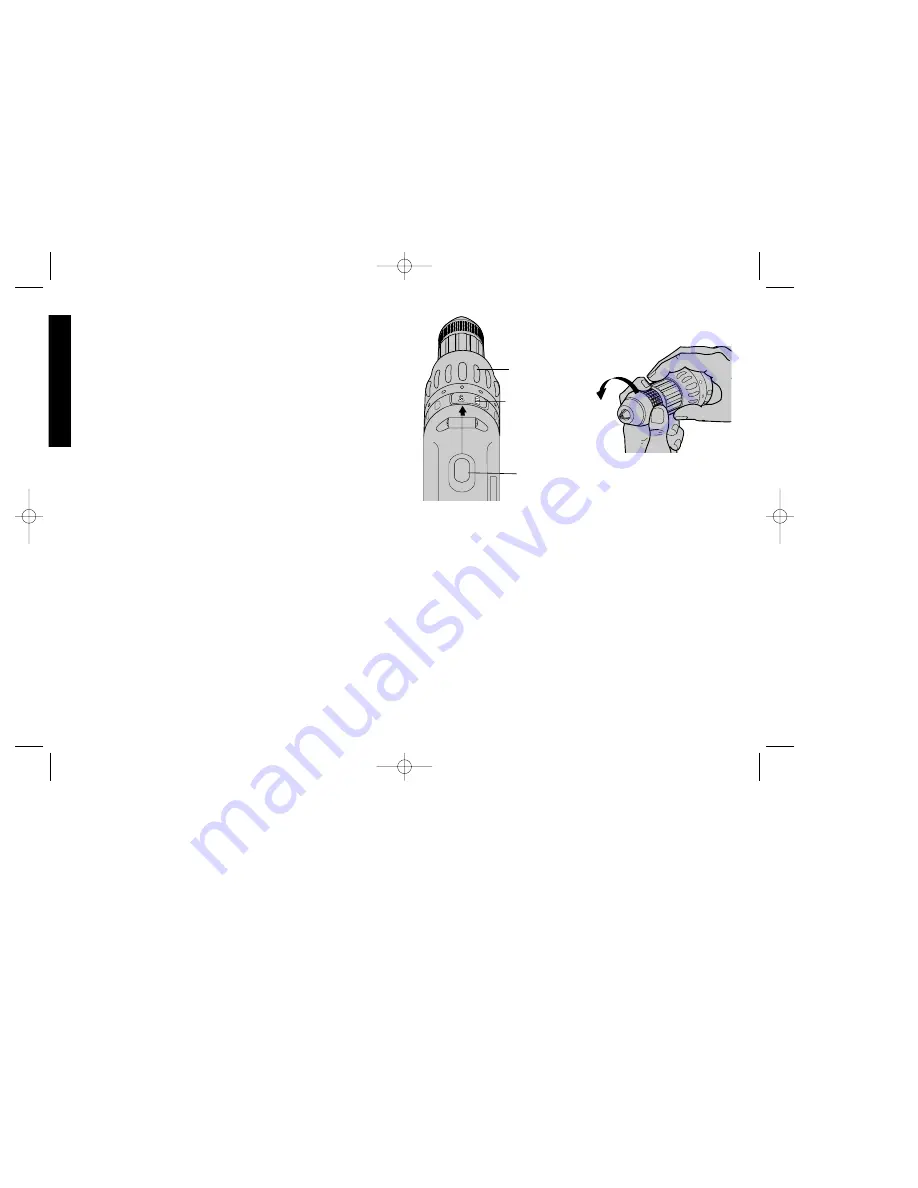

Torque Adjustment Collar

The Versa Clutch feature of your Driver/Drill is an adjustable torque

screwdriver mechanism for driving and removing a wide array of

fastener shapes and sizes. The Versa Clutch allows you to

instantaneously regulate the torque, based on the force applied.

Circling the collar are numbers ranging from 0 to 11. These numbers

(and half numbers designated by dots on the collar) are used to set

the clutch to deliver a torque range. The higher the number on the

6

English

4

3

2

5

collar, the higher the torque and the larger the fastener which can be

driven. To select any of the numbers, rotate until the desired number

aligns with the selector, shown in FIG. 5.

Dual Range Gearing

The dual range feature of your Driver/Drill allows you to shift gears for

greater versatility. To select the low speed, high torque setting

(position 1), turn the tool off and permit to stop. Push the button

forward towards the chuck, as shown in FIG. 5. To select the high

speed, low torque setting (position 2), turn the tool off and permit to

stop. Slide the gear shifter back (away from chuck).

NOTE: Do not change gears when the tool is running. If you are

having trouble changing gears, make sure that the dual range gear

button is either completely pushed forward or completely pushed

back.

Clutch Lock

To lock the clutch for drilling operations, simply move the Driver/Drill

3

2

4

FIG. 5

TORQUE

ADJUSTMENT

COLLAR

DUAL RANGE

GEAR

SHIFTER

DRIVER/DRILL

SELECTOR

FIG. 6

385360/DW974 etc 5/2/02 11:25 AM Page 6