5

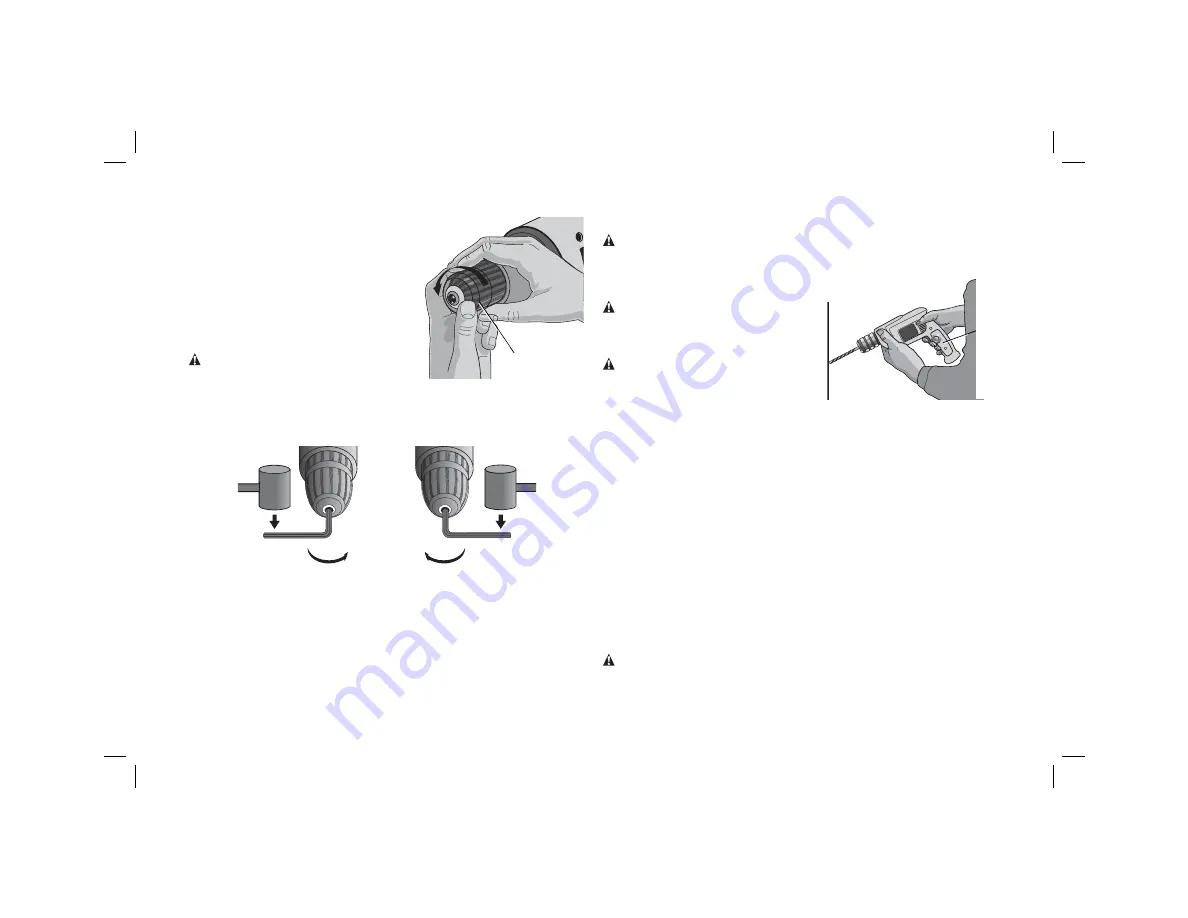

2. Insert the bit or other accessory about

D

FIG. 2

19 mm (3/4") into the chuck and tighten

securely by holding the rear half of the

chuck and rotating the front portion in the

clockwise direction. When the chuck is

nearly tightened, you will hear a clicking

sound. After 4–6 clicks, the chuck is

securely tightened around the accessory.

3. To release the accessory, repeat step 1

listed above.

WARNING:

Do not attempt to tighten drill

bits (or any other accessory) by gripping the

front part of the chuck and turning the tool on.

Damage to the chuck and personal injury may

result.

FIG. 3

FIG. 4

KEYLESS CHUCK REMOVAL (FIG. 3)

Tighten the chuck around the shorter end of a hex key (not supplied). Using a soft

hammer or piece of wood, strike the longer end in the counterclockwise direction.

This will loosen the chuck so that it can be unscrewed by hand.

KEYLESS CHUCK INSTALLATION (FIG. 4)

Screw the chuck on by hand as far as it will go. Tighten the chuck around the shorter

end of a hex key (not supplied) and strike the longer end in the clockwise direction

with a soft hammer.

OPERATION

WARNING: To reduce the risk of serious personal injury, turn tool off and

disconnect tool from power source before making any adjustments or removing/

installing attachments or accessories.

Proper Hand Position (fig. 5)

G

FIG. 5

WARNING:

To reduce the risk of

serious personal injury,

ALWAYS

use

proper hand position as shown in

figure 5.

WARNING:

To reduce the risk of

serious personal injury,

ALWAYS

hold

securely in anticipation of a sudden

reaction.

Proper hand position requires one hand under the the housing, with the other hand on

the main handle (G).

Trigger Switch (fig. 1)

To start the drill, depress the trigger switch; to stop the drill, release the trigger switch.

NOTE:

Use lower speeds for starting holes without a center punch, drilling in metal or

plastics, driving screws or drilling ceramics. Higher speeds are better for drilling wood

and composition boards and using abrasive and polishing accessories.

VARIABLE SPEED

A variable speed trigger switch (A) permits speed control—the farther the trigger is

depressed, the higher the speed of the drill.

For continuous operation, press and hold the variable speed switch, move the lock-on

button (B) up, then release the switch.

To stop continuous operation, press the switch briefly and release it. Always switch

the tool off when work is finished and before unplugging.

Drilling

WARNING:

To reduce the risk of serious personal injury, turn tool off and

disconnect tool from power source before making any adjustments or removing/

installing attachments or accessories.

Summary of Contents for DWDO14S-XE

Page 1: ...DWDO14S XE VARIABLE SPEED REVERSIBLE DRILL INSTRUCTION MANUAL ...

Page 2: ......

Page 10: ...8 ...

Page 11: ...9 ...