10

ENGLISH

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk

of serious personal injury, turn

tool off and disconnect tool from

power source before making any

adjustments or removing/installing

attachments or accessories.

Be sure

the trigger switch is in the OFF position.

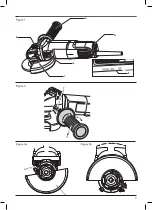

Attaching Side Handle (Fig. 2)

WARNING:

Before using the tool, check

WARNING:

The side handle should

always be used to maintain control of the

Mounting and Removing the Guard

(Fig. 3)

WARNING: To reduce the risk

of serious personal injury, turn

tool off and disconnect tool from

power source before making any

adjustments or removing/installing

attachments or accessories.

Before

reconnecting the tool, depress and

release the trigger switch to ensure that

CAUTION:

Guards must be used with

TO MOUNT THE GUARD

2. Press the guard (C) down (Fig. 3A).

3. Position the guard between your body and

4. Tight the screw (L) holding the cinch collar

firmly around the neck of spindle (Fig. 3B)

TO REMOVE THE GUARD

1. Loosen the screw (L) holding the cinch collar

the screw remains attached to the collar.

remain attached to the collar.

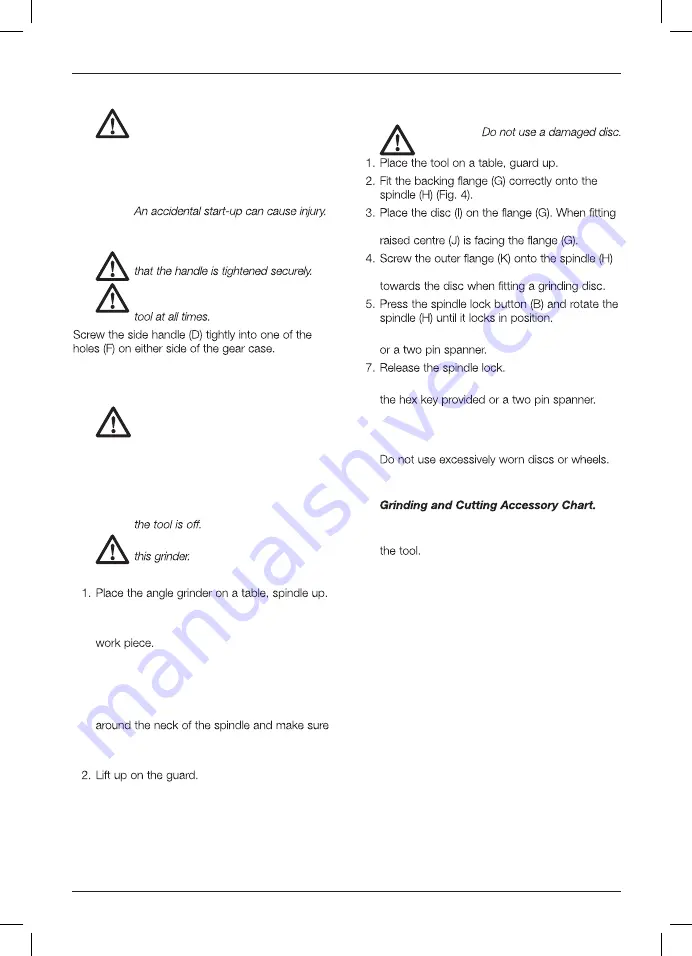

Fitting and Removing a Grinding Disc

(Fig. 1, 4, 5)

WARNING:

a disc with a raised centre, make sure that the

(Fig. 5). The ring on the flange (K) must face

6. Tighten the flange (K) with the hex key provided

8. To remove the disc, loosen the flange (K) with

Prior to Operation

• Install the guard and appropriate disc or wheel.

• Be sure the inner and outer flange are mounted

correctly. Follow the instructions given in the

• Make sure the disc or wheel rotates in the

direction of the arrows on the accessory and

Variable Speed Dial (Fig. 1)

• The variable speed dial (M) offers added tool

control and enables the tool to be used at

optimum conditions to suit the accessory and

material.

Turn the variable speed dial (M) to the desired

level. Turn the dial upward for higher speed

and downward for lower speed.

•

Summary of Contents for DWE4119

Page 1: ...DWE4119 ...

Page 2: ...English 5 original instructions ...

Page 3: ...3 A D E D F C E B D A C M L 2 ...

Page 4: ...4 H G K J I K I H G ...

Page 15: ......

Page 16: ...N855938 05 2020 ...